Integrated structure of steam iron and ironing sleeve

An ironing sleeve and integrated technology, applied in the field of irons, can solve the problems of affecting the ironing temperature, inconvenience for users, burnt clothes, etc., and achieve the effects of saving effort, saving costs, and preventing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

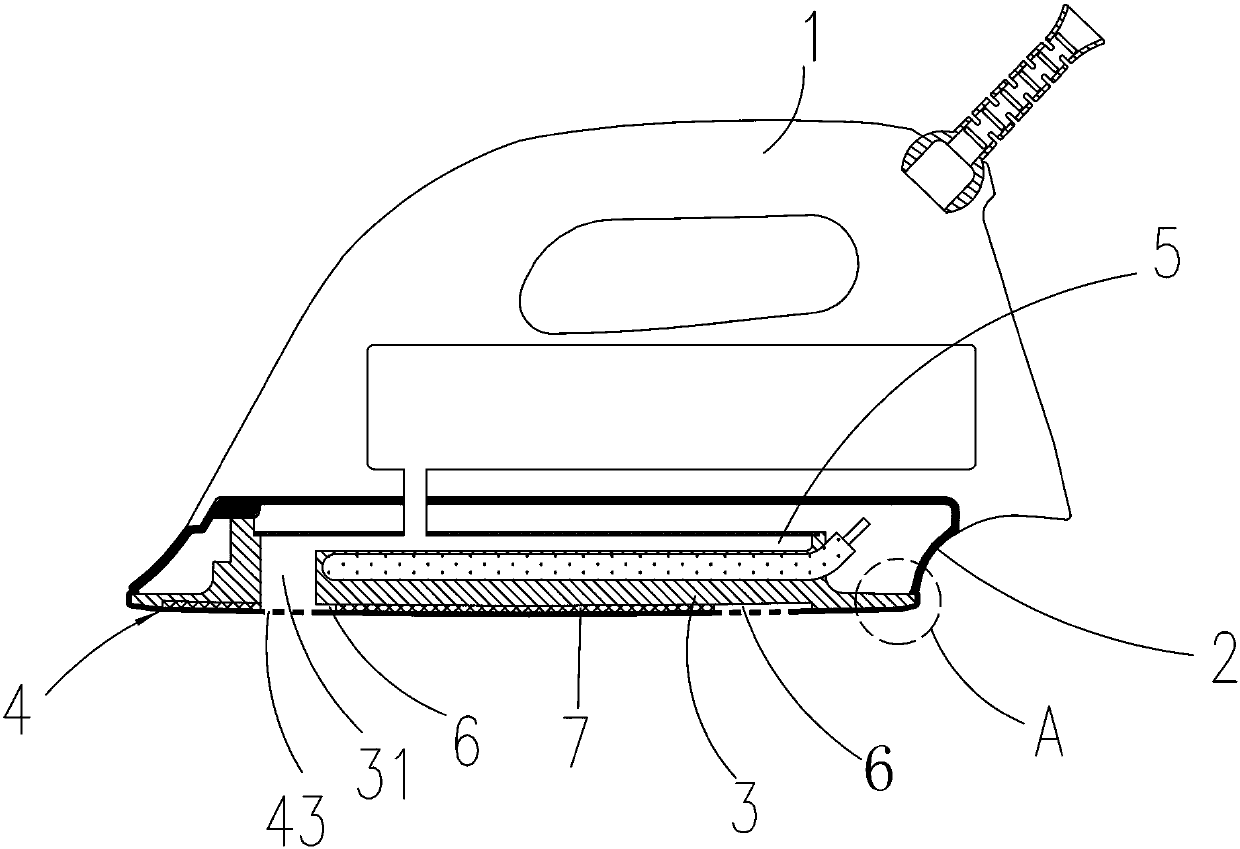

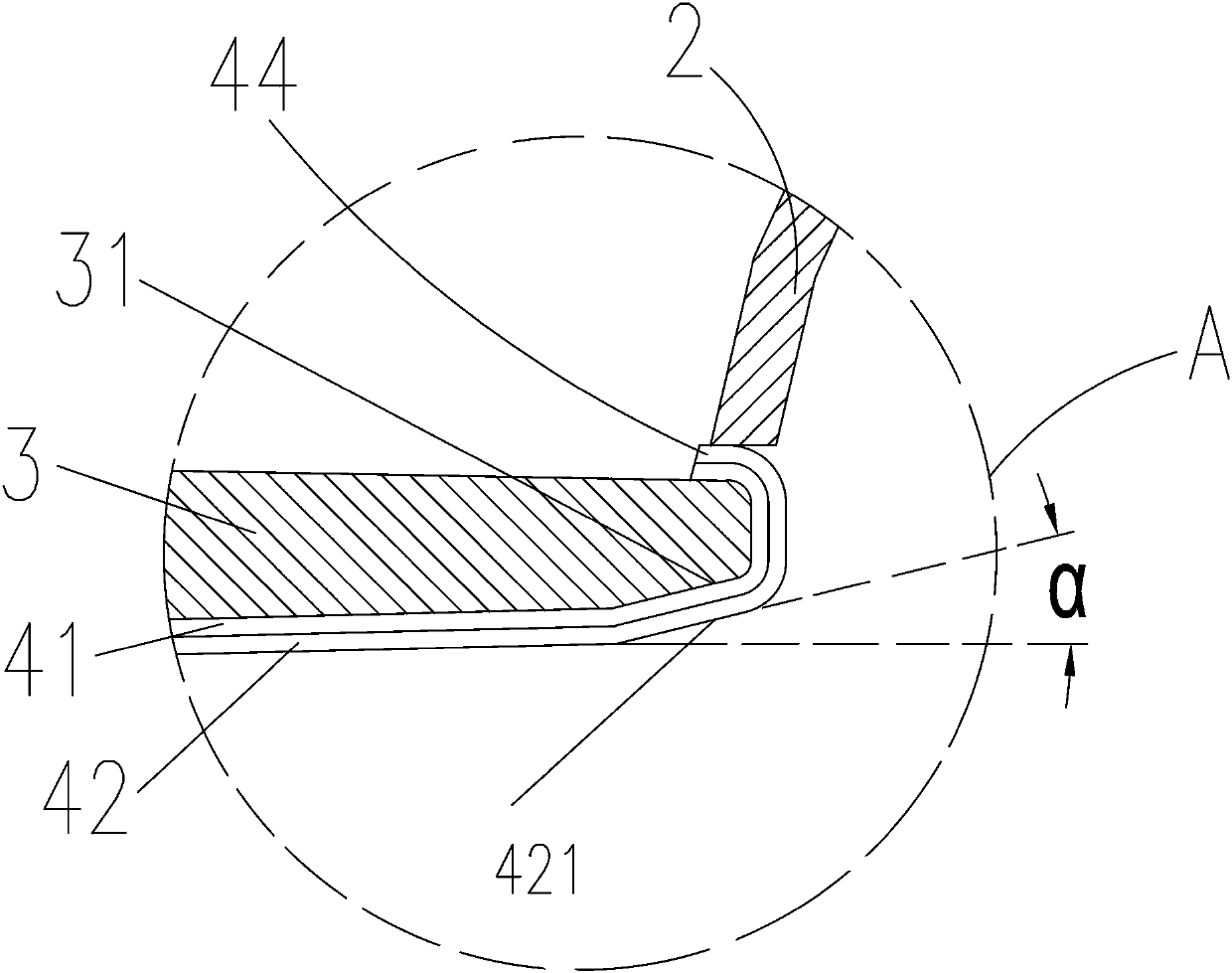

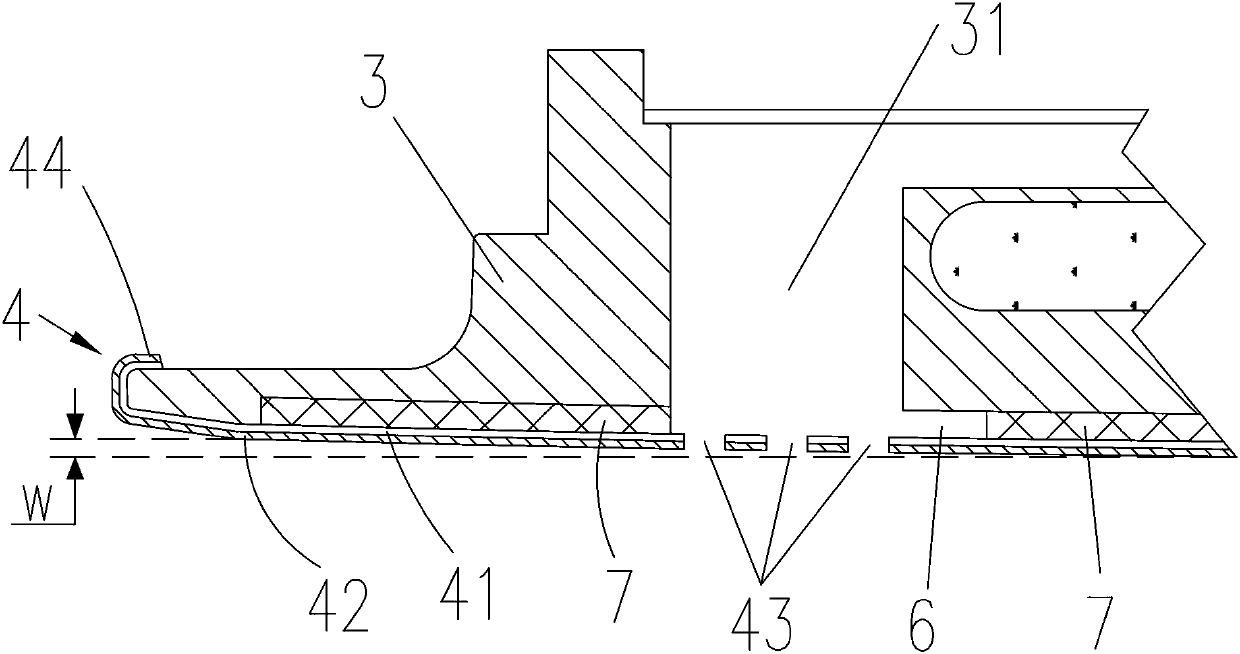

[0035] Such as Figure 1~6 As shown, an integrated structure of a steam iron and an ironing shoe, including an iron main body 1, a heat shield 2 and a bottom plate 3; the heat shield 2 is arranged at the bottom of the main body 1; the bottom plate 3 is fixed on the heat shield 2 At the lower end, the base plate 3 is provided with a steam opening 31; a steam generating space 5 is formed between the base plate 3 and the heat shield 2, and a laminated sheet cover 4 is provided on the base plate 3; the laminated sheet cover 4 includes a heat conducting Layer 41 and heat dissipation layer 42 wrapped outside the heat conduction layer 41; the laminated sheet cover 4 has at least one vent hole 43; the heat conduction layer 41 tightly wraps the bottom edge and the outer periphery of the bottom plate; the heat conduction layer 41 and the bottom plate 3 A steam chamber 6 is formed be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com