A compact track light

A compact structure and track light technology, which is applied in the field of track lights, can solve the problems of increasing production costs, and achieve the effect of reducing the number of increases and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

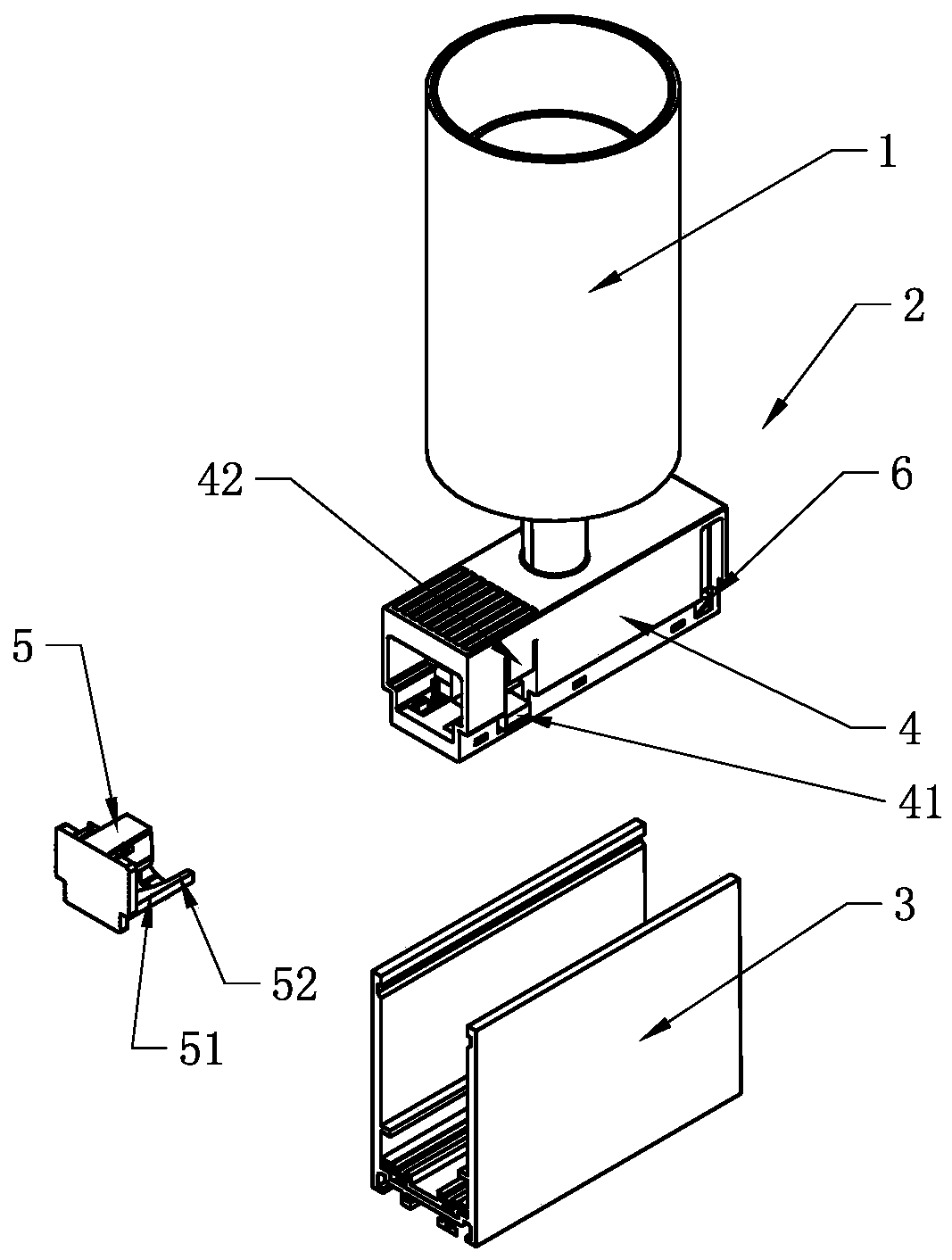

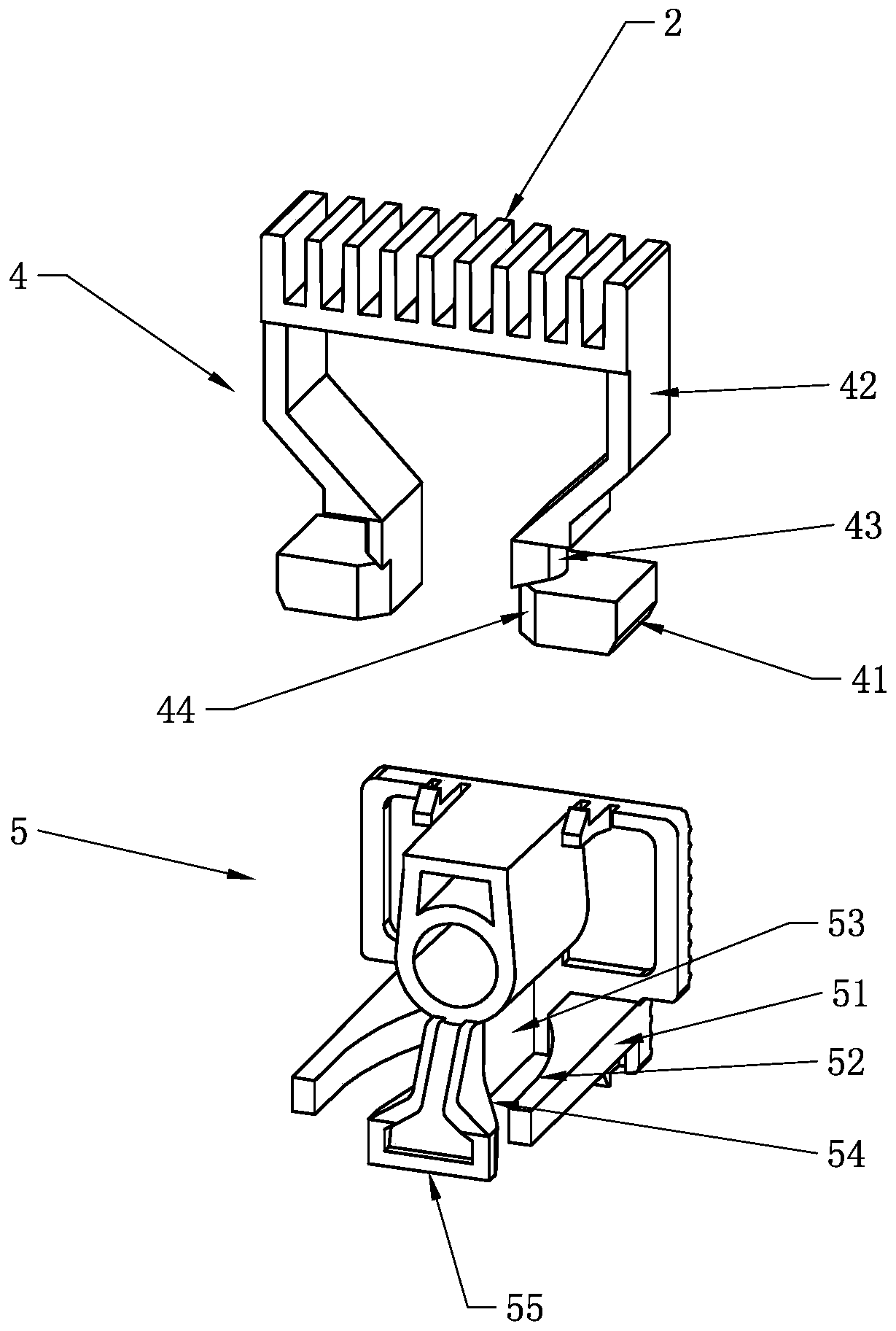

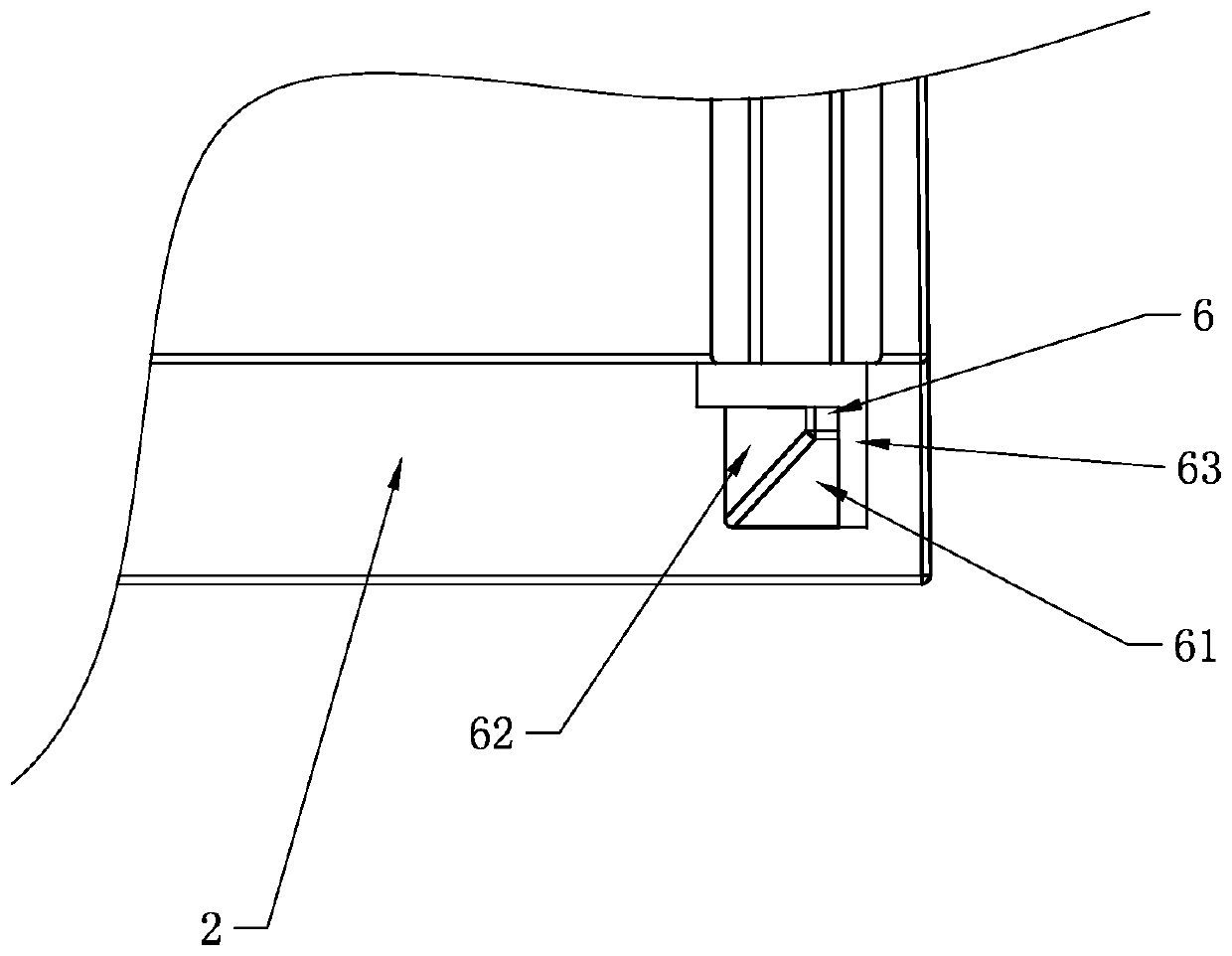

[0020] Such as figure 1 , figure 2 As shown, a compact rail light includes a light body 1, a light rail 3, a light box 2 connecting the light body 1 and the light rail 3, the light box 2 is slidably connected to the light rail 3, and the light box 2 includes a first The body 4, a first cantilever 42 connected to the first body 4, and a first protrusion 41 provided at the end of the first cantilever 42, and the first protrusion 41 is clamped with the light rail 3.

[0021] The first protrusion 41 slides in the slot of the light rail 3 so that the light box 2 can slide along the light rail 3 without being separated from the light rail 3.

[0022] In order to facilitate the disassembly and assembly of the light box 2, the first body 4 is provided with a button 5 for disengaging the first protrusion 41 from the light rail 3. The button 5 is provided with a second cantilever 51, and one end of the second cantilever 51 facing away from the button 5 and The first cantilever 42 abuts.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com