A method for measuring the tensile strength of gleeble high temperature compression specimens

A tensile strength, high temperature compression technology, applied in the direction of applying stable tension/compression to test material strength, strength characteristics, measuring devices, etc., can solve problems such as difficulty in determining accuracy, and achieve true tensile strength and accurate results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) Cut the Gleeble high-temperature compressed small round cake sample into thin slices with a thickness of 1 mm to 2 mm in the radial direction by wire cutting;

[0020] 2) After inlaying the cut thin slice sample with a hot mounting machine, grind and polish it with a metallographic grinding machine to make the thickness uniform and the surface roughness better than R a 1.6μm, remove the mounting material and take out the thin slice sample; repeat the above steps to grind and polish the other side;

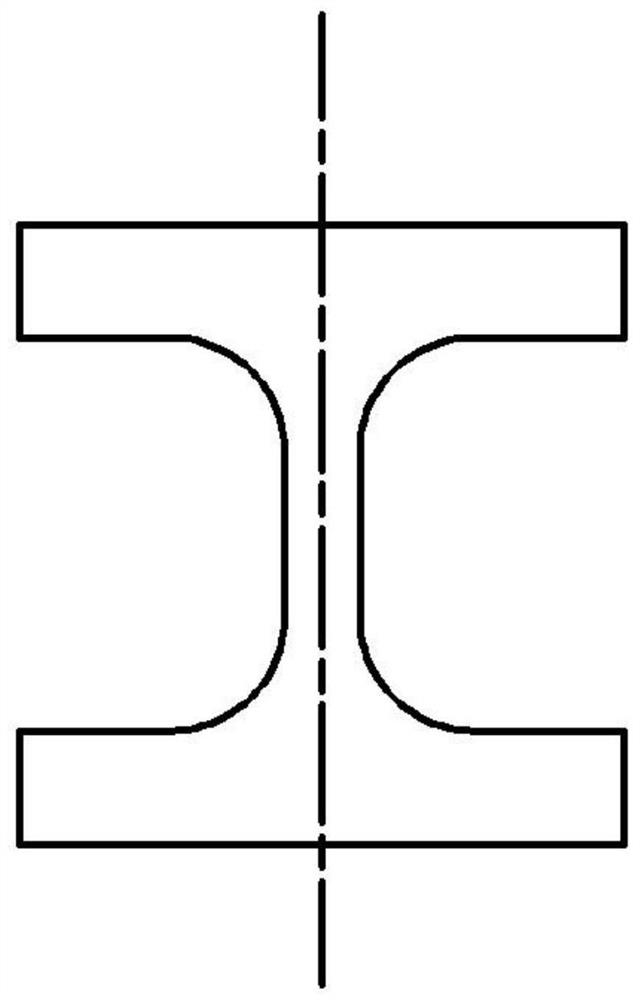

[0021] 3) Cut the ground and polished thin slice sample into an I-shaped sample with a width of 1 mm to 2 mm, a parallel length of 3 mm, and a transition arc R of 1.5 mm;

[0022] 4) Cut the I-shaped sample (such as figure 1 shown) fixed on a small cloth grinder, and the side of the sample was ground to make the surface roughness on both sides better than R a 1.6μm;

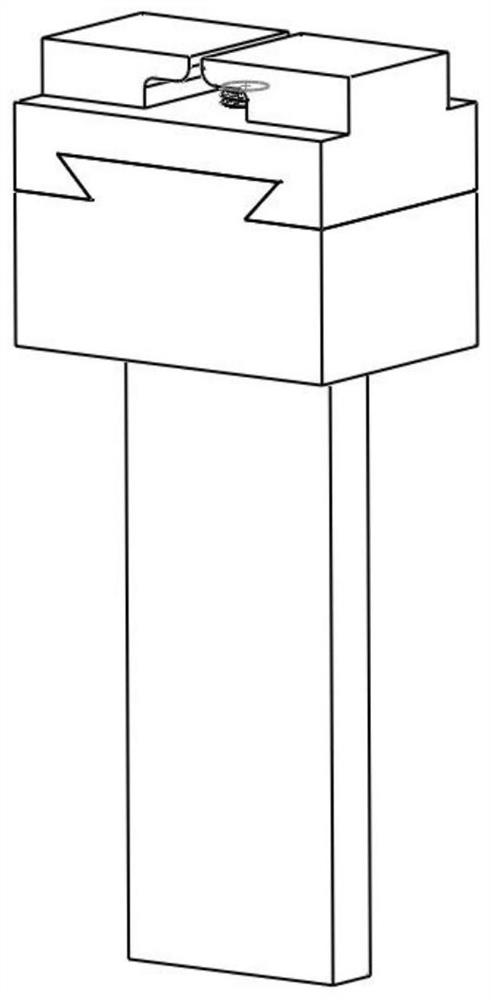

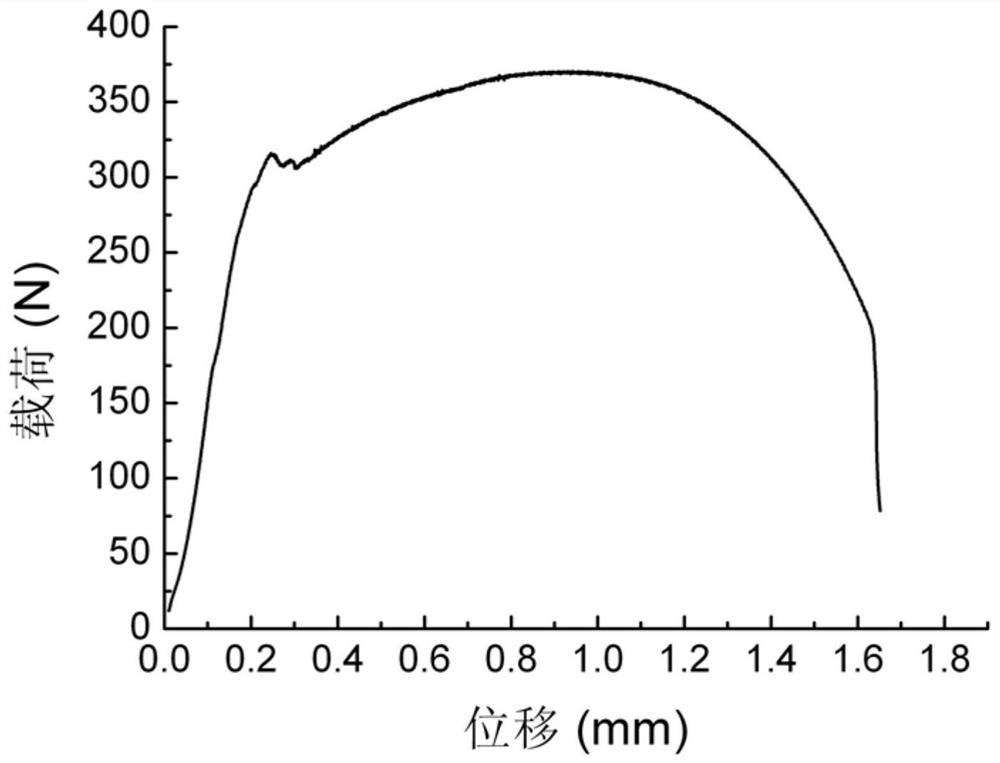

[0023] 5) Put the ground I-shaped wheel sample into the self-made fixture matched with the 5kN materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com