Towel rack with preassembled installation screws

A towel rack and screw technology, applied to household appliances and other directions, can solve the problems of tediousness, prolonged installation time, low efficiency, etc., and achieve the effects of improving installation efficiency, small installation steps, and small structural changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

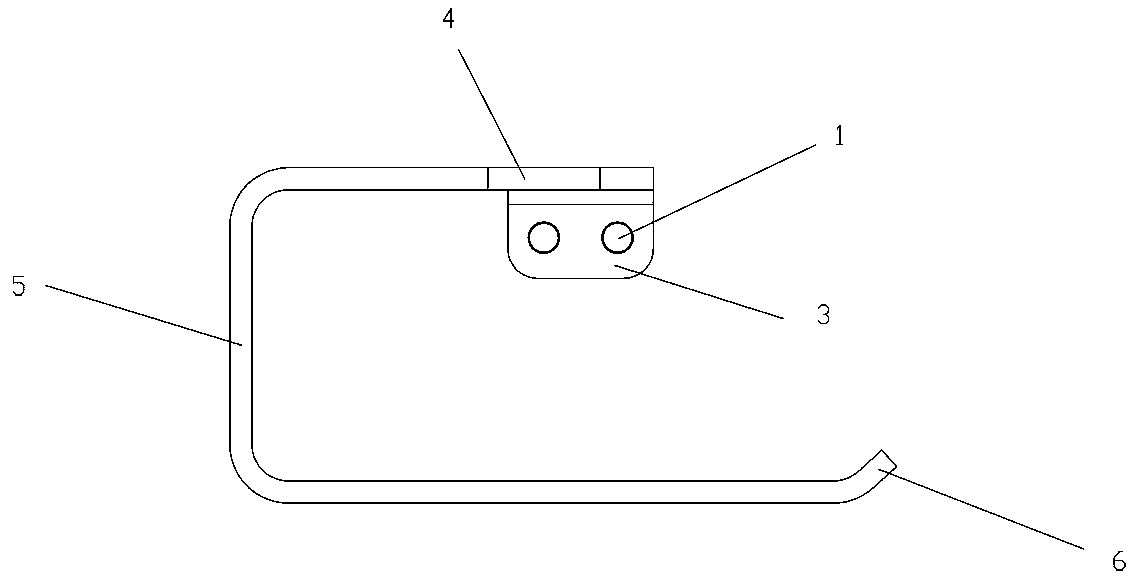

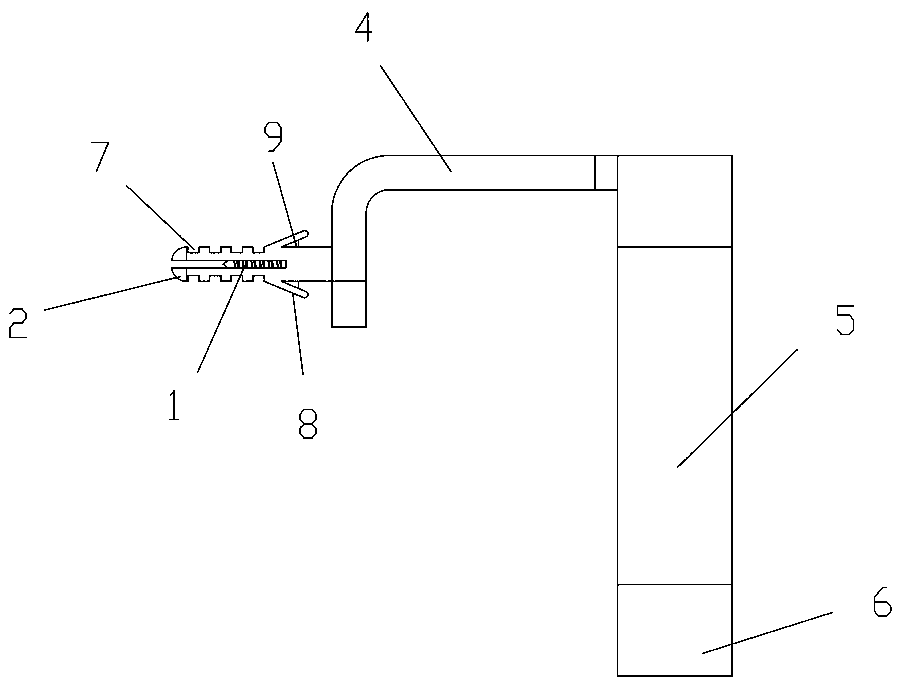

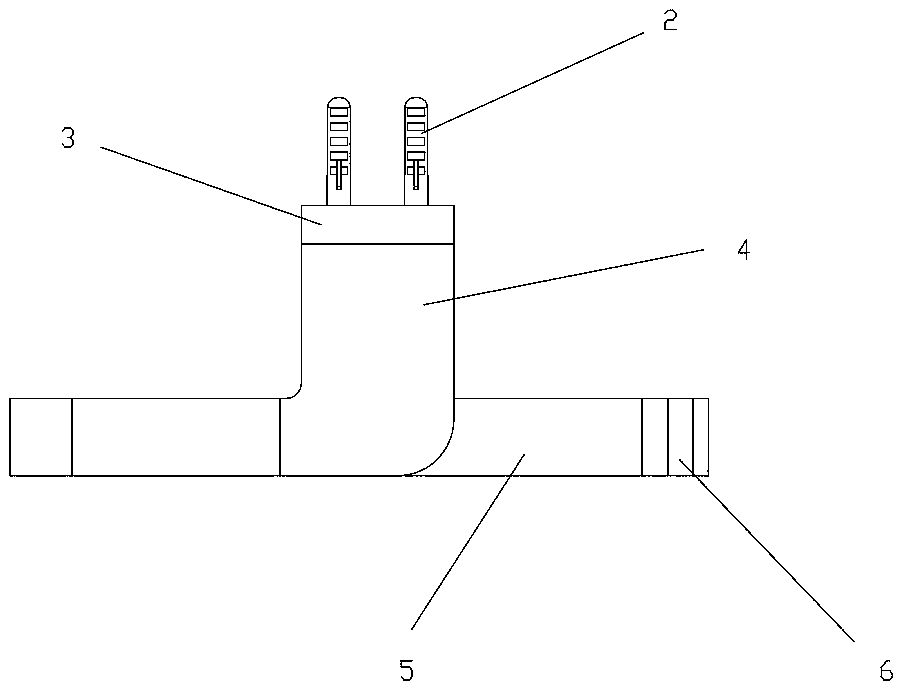

[0012] The towel rack with pre-installed mounting screws described in Example 1 includes a main body of the towel rack. The mounting surfaces at both ends of the main body of the towel rack are provided with mounting screws 1 that form an integral structure with the main body of the towel rack. There is an explosion-proof rubber sleeve 2, and the explosion-proof rubber sleeve is fixedly installed with the mounting screws in a fixed and stuck form; a connecting gasket 3 is also provided between the main body of the towel rack and the mounting screw, and the connecting gasket and the main body of the towel rack are integrally connected Structure; the main body of the towel rack includes a connecting plate 4 integrally formed with mounting screws, a C-shaped hanging rod 5 formed integrally with the connecting plate, and the hook end 6 of the hanging rod protrudes relative to the position of the connecting plate , The end of the hook end is tilted up to prevent the towel from slipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com