An overhead crane wheel structure

A technology of bridge cranes and wheel sets, which is applied in the direction of traveling mechanism, mechanical equipment, load suspension components, etc., which can solve the problems that the wheel sets cannot be quickly disassembled, unfavorable for precise control of the crane, and slow braking of the wheel sets, etc. Disassembly and maintenance, precise and rapid positioning, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

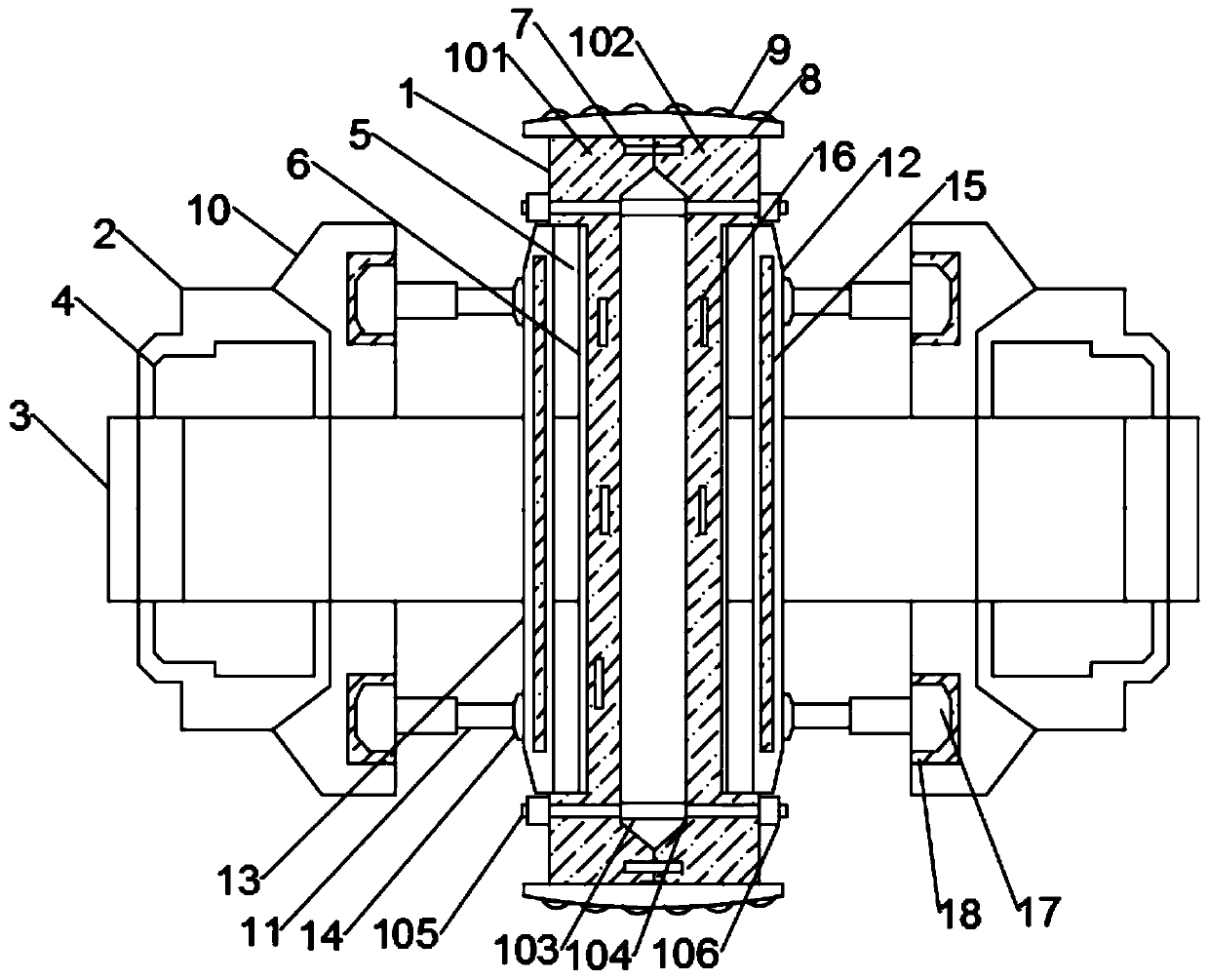

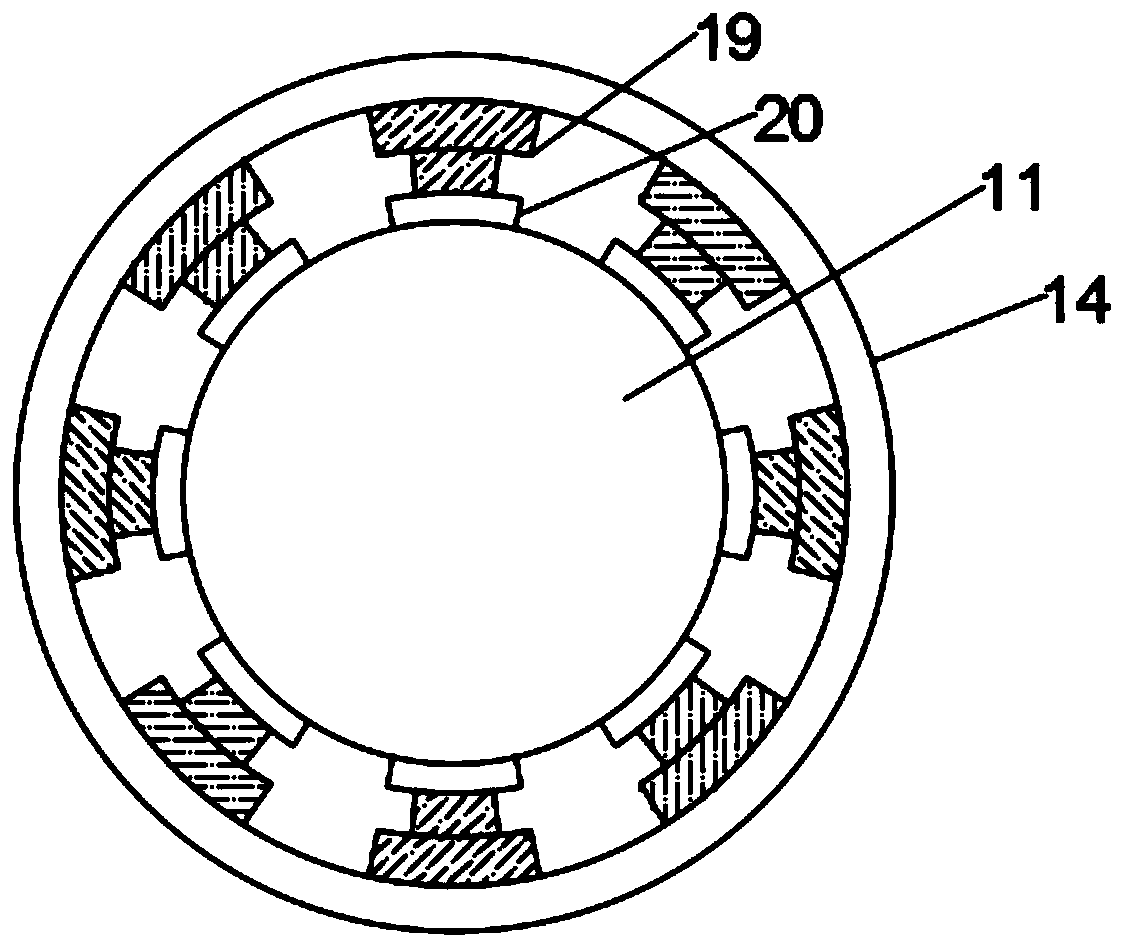

[0021] Such as figure 1 and figure 2 As shown, the present invention provides a wheel set structure of an overhead crane, comprising a wheel 1, a bearing box 2 and a wheel axle 3, the wheel axle 3 is connected at the center of the wheel 1, and the bearing box 2 is installed on the wheel axle 3 surface, the wheel 1 rotates around the wheel shaft 3 through the bearing 4, the wheel 1 includes a first wheel 101 and a second wheel 102, and the first wheel 101 and the second wheel 102 pass through The connecting shaft 103 is connected together, the surface of the first wheel 101 and the second wheel 102 are provided with connecting holes 104, the two ends of the connecting shaft 103 are connected with a positioning screw 105, and the positioning screw 105 passes through a nut 106 It is fixed on the surface of the first wheel 101 and the second wheel 102, and the connecting shaft 103 is closely attached to the first wheel 101 and the second wheel 102, and the first wheel 101 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com