Simulation test device and method of evaluating stress corrosion cracking resistance of well logging steel wire

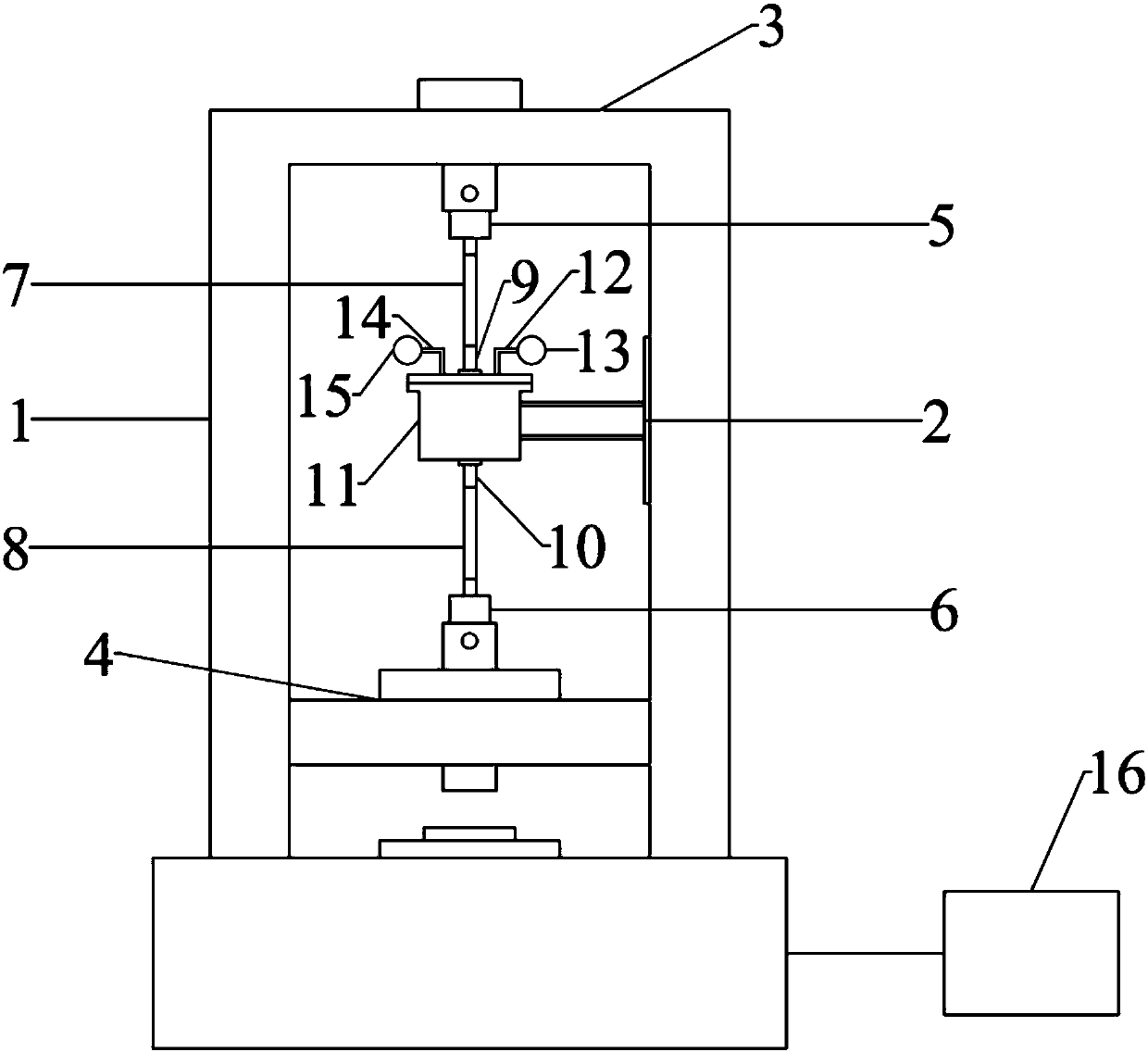

A corrosion cracking and simulation test technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, using stable tension/pressure to test material strength, etc., can solve the problem that the steel wire load and strain rate of the pulling speed change and cannot be changed Problems such as load state simulation and difficult small-sized steel wire sample sealing are achieved to ensure accuracy and authenticity, reasonable sample clamping methods, and easy and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

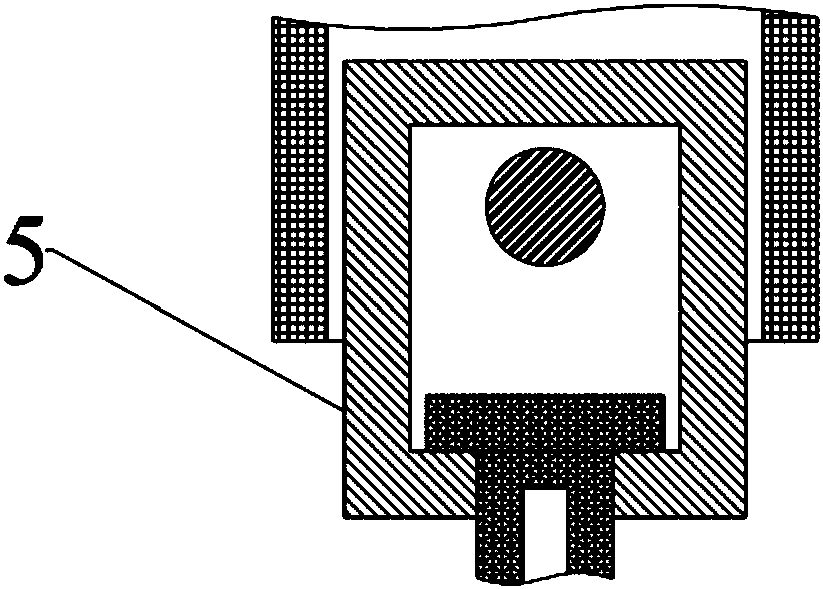

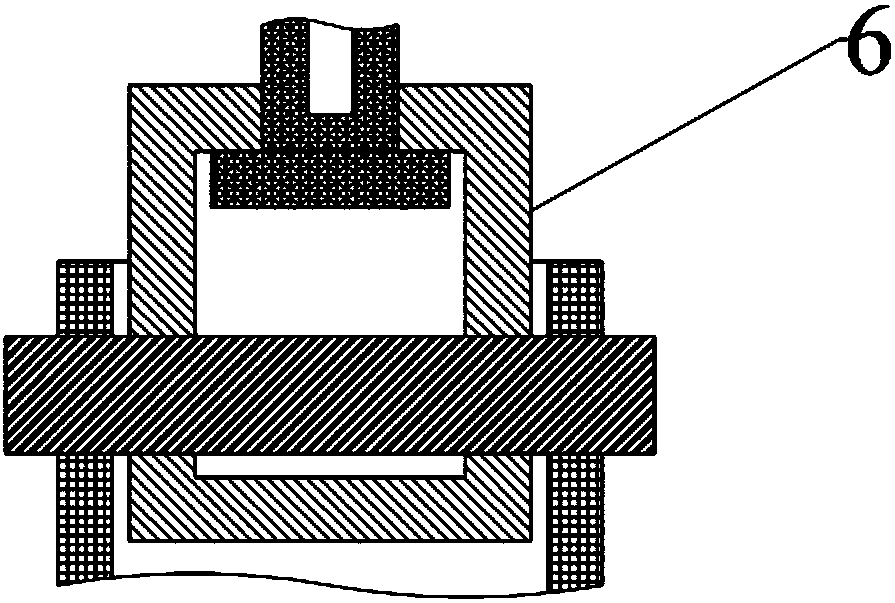

[0051] Example 1: Taking the evaluation of Φ3.0mm D659 stainless steel well logging steel wire used in sour oil and gas for its resistance to stress corrosion cracking during down-well wax removal operations as an example, the test steps are as follows:

[0052] (1) Take a steel wire sample of suitable length, pass through the upper and lower clamps with a through hole diameter of 3.0mm, and wind the two ends of the steel wire to be tested in the clockwise and counterclockwise directions for three turns with a winding diameter of 4.0mm on the winding machine. , Use a vernier caliper to adjust the position of the steel wire clamping section and the test section to ensure that the length L of the steel wire test section is 100mm, and straighten the two ends of the centering wire

[0053] (2) Heat the ZChSnSb8-8 tin-based alloy in a muffle furnace to 400°C to melt it completely, and then pour it into the upper and lower clamps. The melt surface can completely cover the winding end and ...

Embodiment 2

[0062] Example 2: Taking the evaluation of the stress corrosion effect of Φ3.0mm D659 stainless steel logging wire used in sour oil and gas on its mechanical properties as an example, the test steps are as follows:

[0063] Repeat steps (1) to (7) in Example 1;

[0064] (8) Set the strain rate to 0.1mm / min through the computer processing system, and start the tensile test;

[0065] (9) Stop the test when the sample breaks;

[0066] (10) Clear the corrosion products, put the fractured samples together, use the vernier caliper to measure the length L of the sample after the fracture, and calculate the elongation; use the vernier caliper to measure the diameter of the steel wire at the fracture to calculate the section shrinkage; use the computer processing system to output the stress-strain curve , Calculate the tensile strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com