Systems and methods for monitoring parameters of semiconductor factory automation systems

An automation system and semiconductor technology, applied in general control systems, semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, etc., can solve the problems of cumbersome and slow automation system errors and deviations, and difficulty in identifying automation systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Reference will now be made in detail to the disclosed subject matter illustrated in the accompanying drawings.

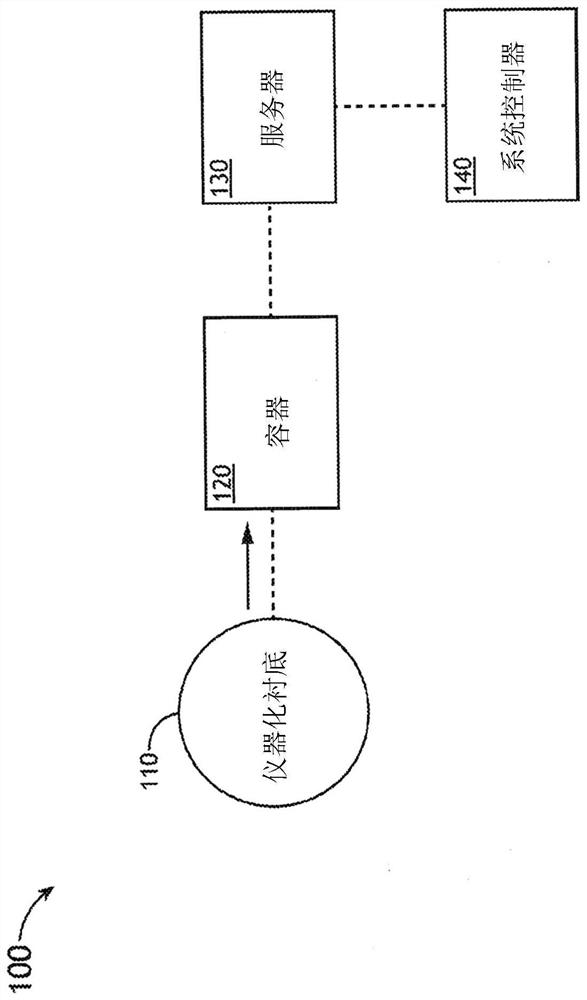

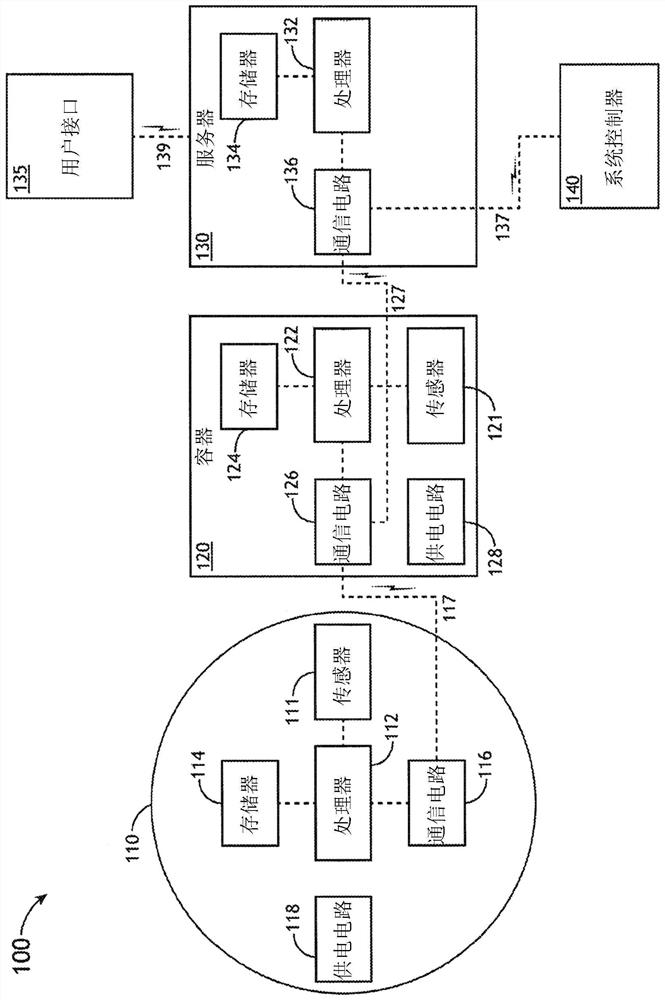

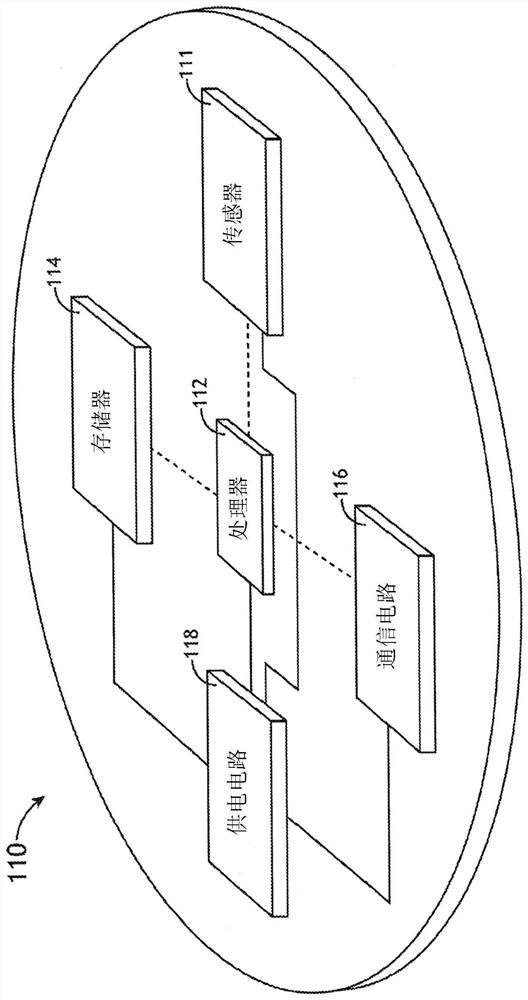

[0027] generally refer to Figures 1A to 4B A system and method for monitoring one or more conditions of a semiconductor automation system in accordance with one or more embodiments of the present invention will be described. Embodiments of the present invention are directed to automatic measurement and / or monitoring of one or more parameters and / or conditions of an automation system of a semiconductor factory or production line. For example, parameters and / or conditions measured and / or monitored by embodiments of the invention may include, but are not limited to, leveling, teaching, alignment, cleanliness, pressure, and / or health of an automated system. Such automated systems may include, but are not limited to, automated material handling systems (such as overhead transport systems, automated warehouses, and the like) and FOUP / wafer handling systems for ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com