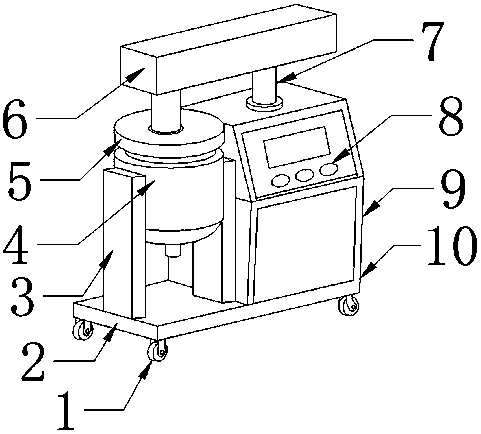

Paste making machine convenient for cleaning

The technology of a paste making machine and a chassis is applied to mixers, mixers, mixer accessories and other directions with a rotary stirring device, which can solve the problems of difficult manual operation by staff, heavy cream quality, time-consuming and labor-intensive, etc., and achieves higher cleaning. Convenience, improving ease of use, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

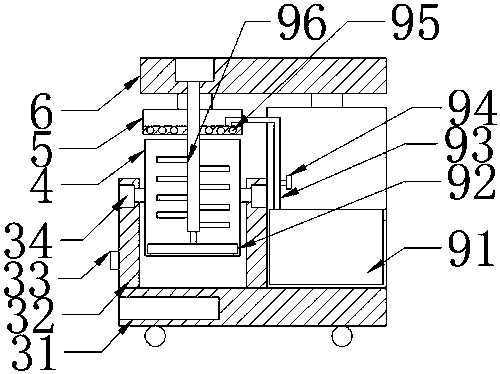

[0023] Specific embodiments: after the cream is stirred inside the emulsification pot 4, the staff presses the rotary switch 33, switches the rotary switch 33 to the on state, the storage battery 31 transmits the electric energy to the rotary motor 34, and the rotary motor 34 converts the electric energy into mechanical energy, The rotating motor 34 drives the emulsifying pot 4 to rotate, which is convenient for pouring out the finished paste for centralized storage and use, which increases the convenience of use of the present invention.

[0024] The staff connects the storage battery 31 to the water pump 94, and the water pump 94 starts to work. The water pump 94 transports the cleaning water in the liquid storage tank 91 to the high-pressure nozzle 95 through the telescopic tube 93, and the high-pressure nozzle 95 sprays the cleaning water to the emulsification pot 4. The inner wall and the outer surface of the stirring blade are continuously sprayed with cleaning water by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com