Rice processing screening equipment

A screening equipment and rice processing technology, which can be used in sieves, grids, and the use of liquid separators. High efficiency and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

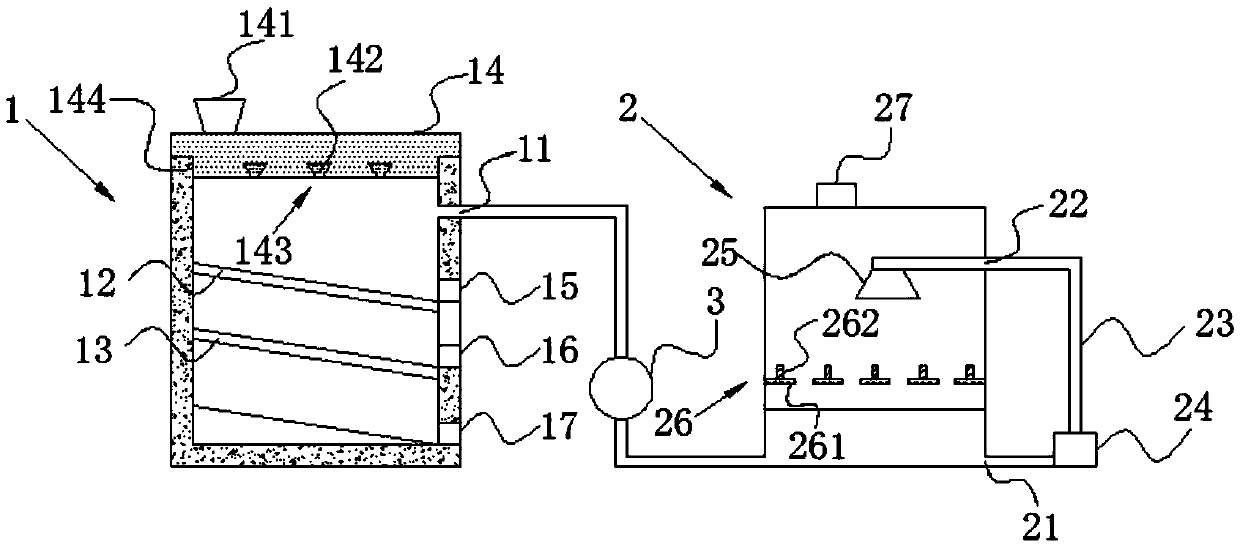

[0020] Embodiment: a kind of rice processing and screening equipment, such as figure 1 As shown, it includes a screening room 1 and a dust removal box 2. The upper end of the side wall of the screening room 1 is provided with an air suction port 11, and the air suction port 11 is connected with the lower end of the side wall of the dust removal box 2 by a blower fan 3. The screening Chamber 1 comprises primary effect screen cloth 12, medium effect screen cloth 13 and the top cover 14 that is positioned at the top of screening room, and described top cover 14 has feed inlet 141, and described primary effect screen cloth 12 is positioned at described medium effect screen cloth 13 Above, the bottom surfaces of the primary effect screen 12, the intermediate effect screen 13 and the screening chamber 1 are all inclined downward along the sliding direction of the rice;

[0021] Described top cover 14 also has several magnets 142, and several described magnets 142 are mutually parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com