A shared platform for automotive acoustic component cooling assembly fixtures

A technology of acoustic components and cooling groups, which is applied in the field of shared platforms for cooling group fixtures, can solve problems such as inability to share, and achieve the effects of easy operation, convenient manufacture, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific drawings and embodiments.

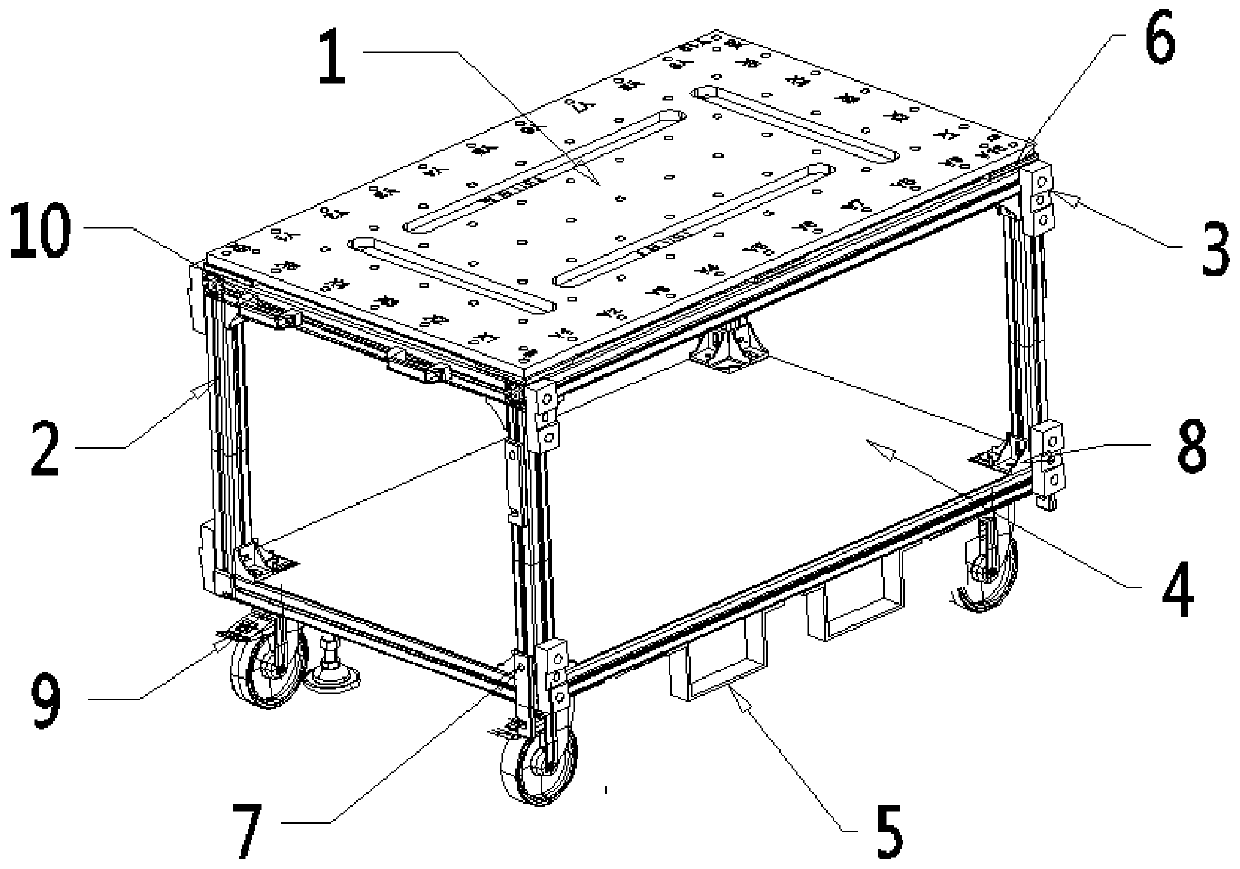

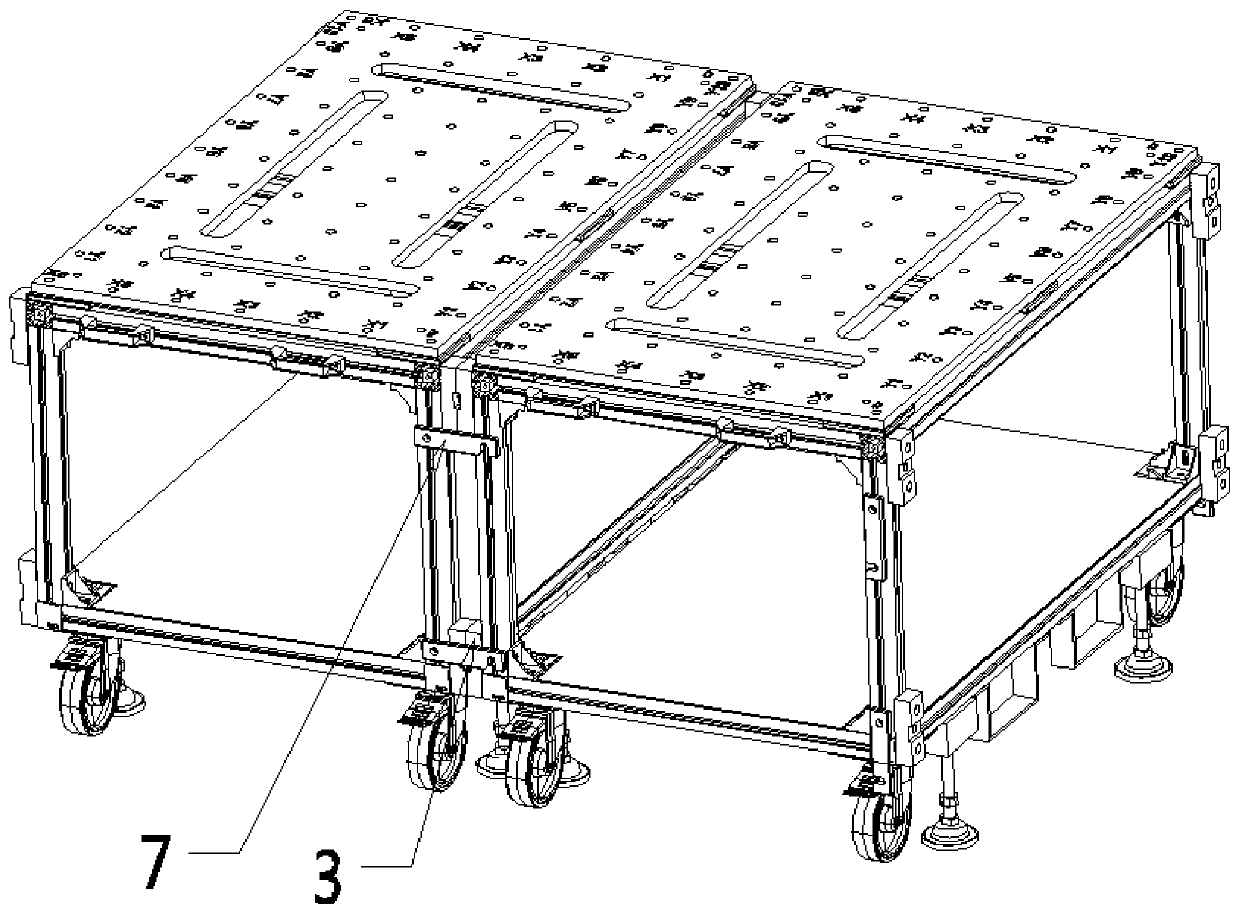

[0023] like Figure 1-2 Shown: a common platform for automotive acoustic component cooling assembly fixtures, characterized in that it includes:

[0024] Bottom plate 1, sealing plate 4 and fixture frame; the bottom plate is used to place the 3D printing fixture, and the sealing plate is used to collect the remaining materials of the product;

[0025] The fixture frame includes a bracket 2, a connecting block 3, a forklift hole 5, a connecting hanging plate 7, flat casters 9 and a handle 10;

[0026] The sealing plate and the bottom plate are distributed parallel to each other, and brackets 2 are arranged at the corresponding four corners between the two; the brackets 2 are respectively connected to the sealing plate and the bottom plate through connecting blocks 3; the connecting blocks are arranged on two adjacent The outer end surface of the support 2 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com