Cloth barrel clamping device

A technology of clamping device and cloth tube, which is applied in the direction of packaging, transportation and packaging, and external frames, etc., can solve the problem of damage to the cloth, and achieve the effects of not easy to damage the cloth, small size, and avoiding falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below by means of specific embodiments:

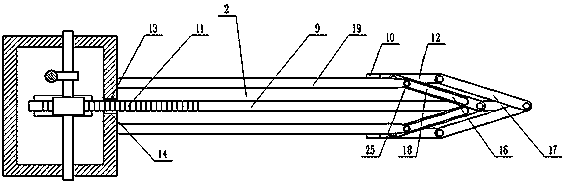

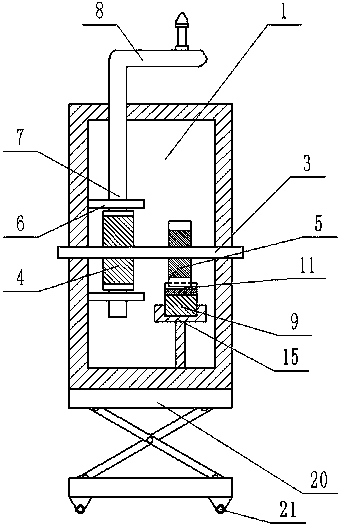

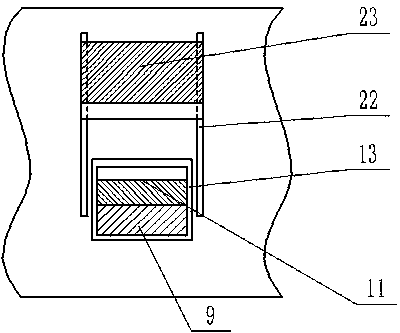

[0037] The reference signs in the drawings of the description include: box body 1, pressing mechanism 2, rotating shaft 3, worm wheel 4, gear 5, worm base 6, worm 7, rotating rod 8, push rod 9, telescopic end 10, rack 11. Pressure rod 12, sliding hole 13, gap 14, push rod slide seat 15, first connecting rod 16, second connecting rod 17, chute 18, positioning rod 19, lifting platform 20, roller 21, slide rail 22, Lock slide block 23, cloth tube 24, rotating shaft 25.

[0038] Such as figure 1The cloth tube clamping device shown includes a box body 1 with an inner cavity structure and a pressing mechanism 2. The box body 1 is provided with a sliding hole 13, and the pressing mechanism 2 includes two positioning rods parallel to each other. 19. The two positioning rods 19 have the same length, and one end of the positioning rod 19 is fixedly connected to the box body 1. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com