Rotatable blade flow-guiding device for notched box girder bridge

A technology of rotating blades and diversion devices, applied in bridges, bridge parts, bridge construction, etc., can solve the lack of adjustability or controllability of wind-induced vibration changes, affecting the vision of bridge walking or driving, and insufficient device connection. Firmness and other issues, to achieve the effect of easy installation and disassembly, long service life, convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

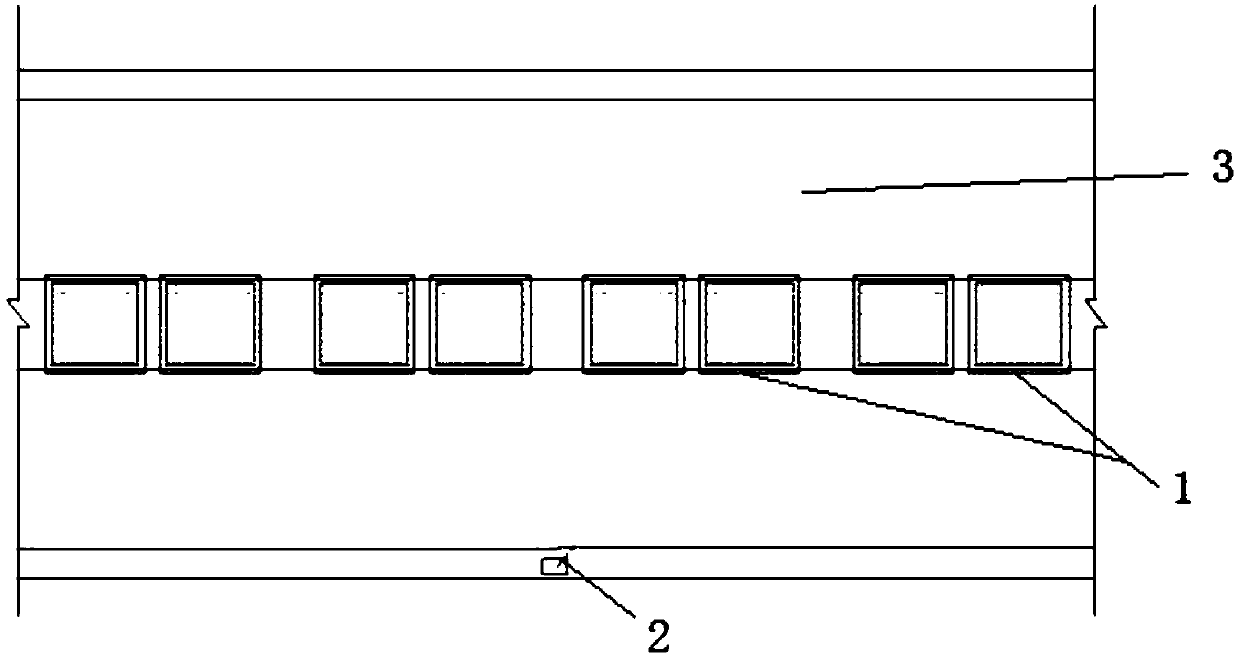

[0044] A rotatable vane deflector for slotted box girder bridges, see Figure 1-Figure 4 , including a plurality of vane flow guide units 1 and wind speed measuring devices 2 arranged side by side at each slot, figure 1 8 are shown in , and two adjacent vane flow guiding elements 1 are arranged independently of each other.

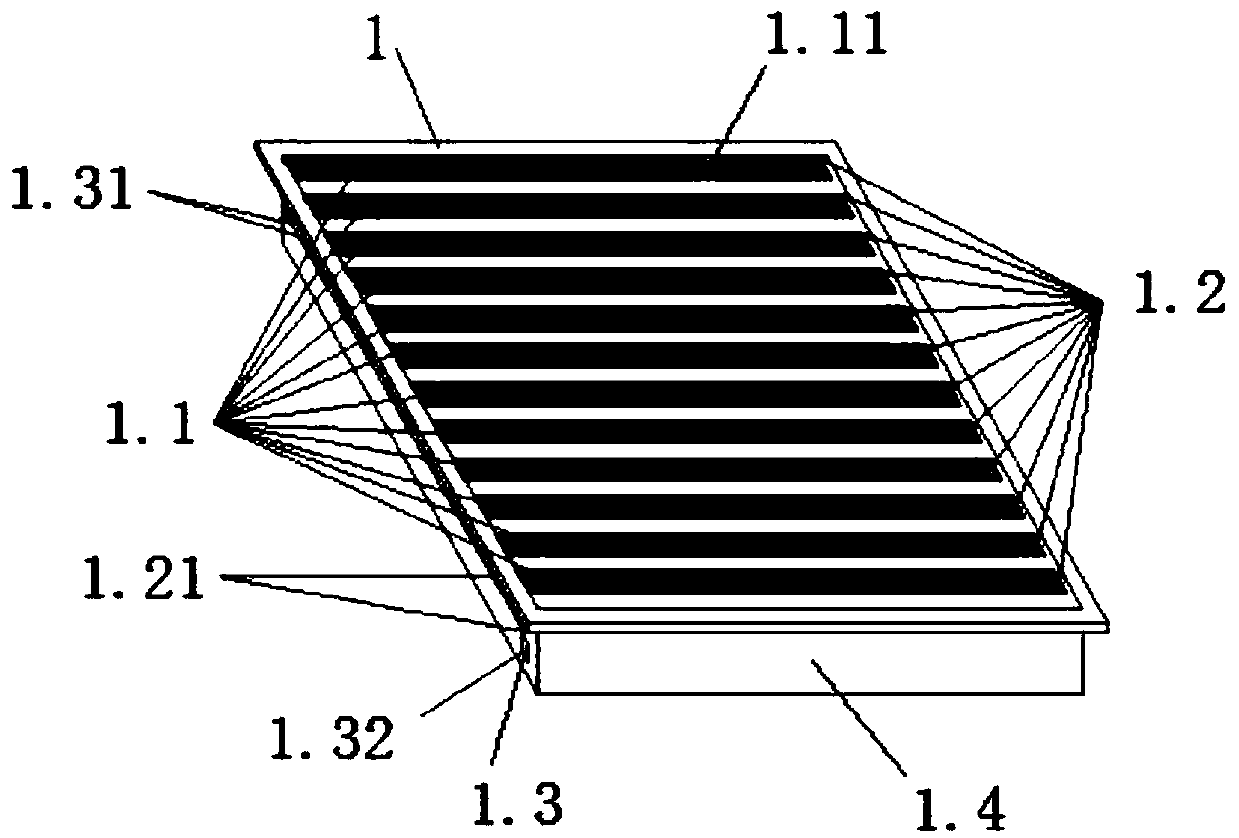

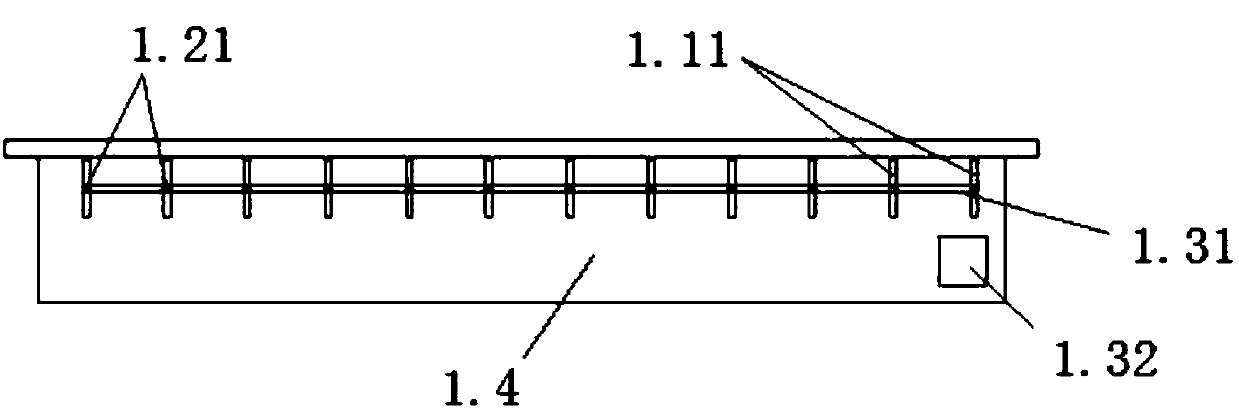

[0045] For the structure of the vane guide unit 1, see Figure 2-Figure 4 , including guide vane group 1.1, rotating shaft group 1.2, rotating power source 1.3 and frame 1.4, details are as follows:

[0046] The guide vane set 1.1 includes a plurality of guide vanes 1.11 ( figure 2 and image 3 Twelve pieces are shown in the figure), a plurality of guide vanes 1.11 are arranged side by side (arranged from left to right here), and the minimum distance between two adjacent guide vanes 1.11 is 1- 10 mm, preferably 2-5 mm; the minimum distance between the two guide vanes 1.11 at the ends (here may be the leftmost and rightmost ends) to the inner wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com