Pool cleaner

A technology for cleaners and pools, applied in swimming pools, public buildings, gymnasiums, etc., can solve problems such as huge workload, inability to clean pool walls, and poor user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

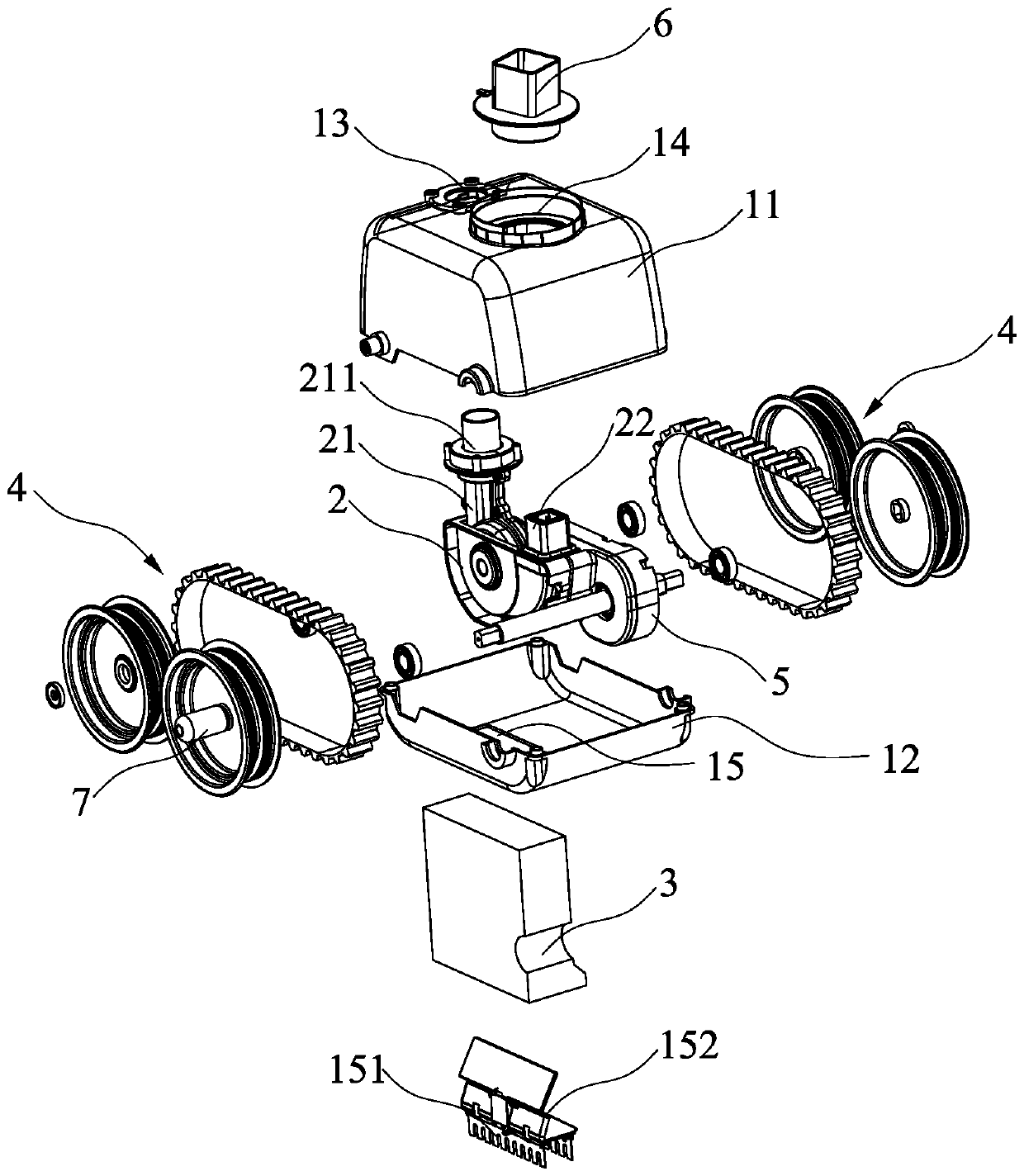

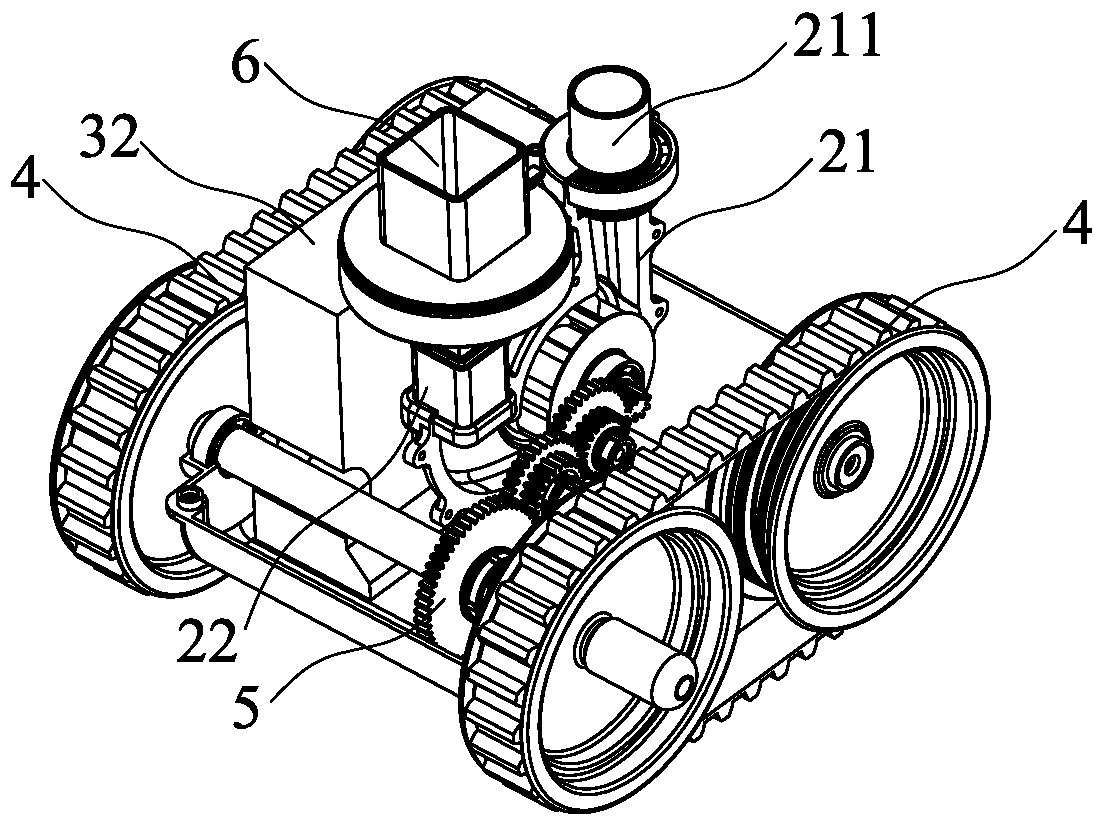

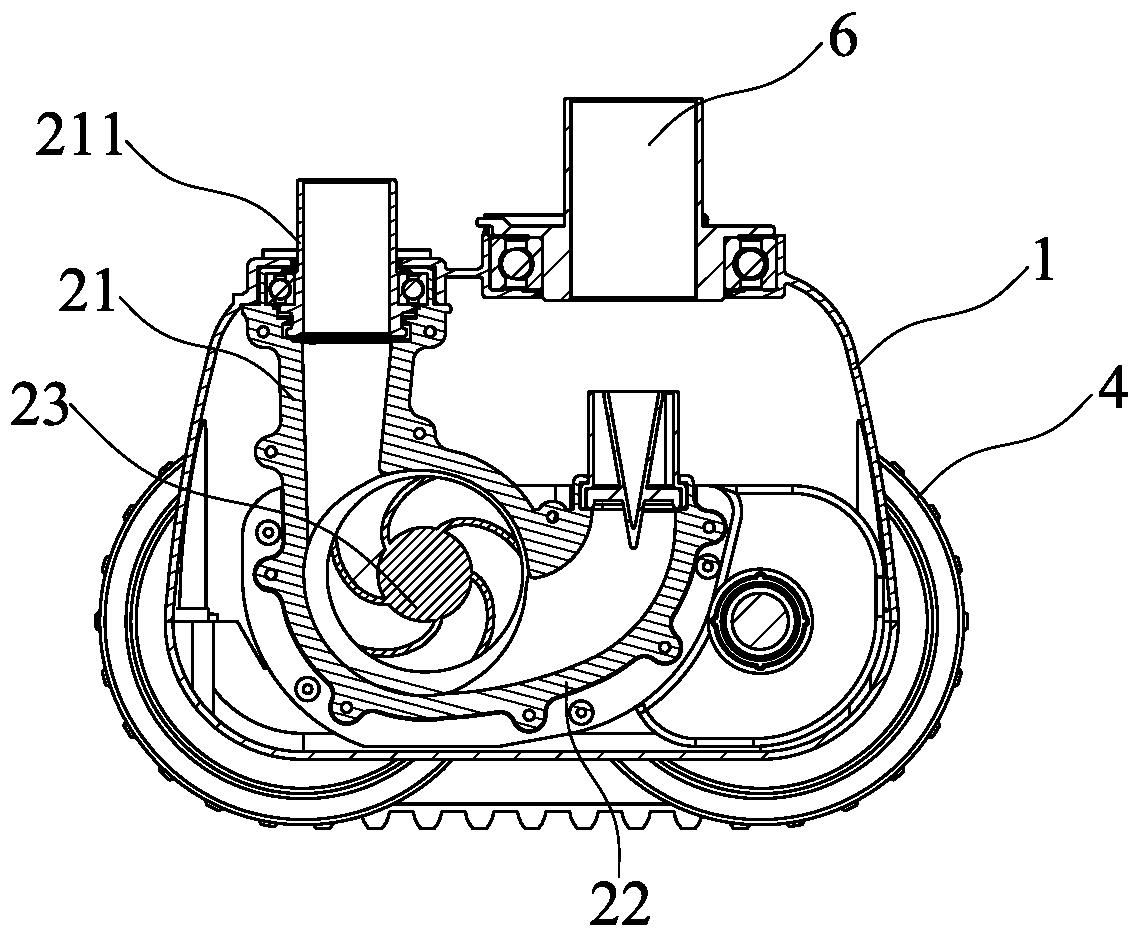

[0039] Such as Figure 1 to Figure 9 As shown, the pool cleaner of the present invention includes a housing 1, a hydraulic drive device 2, and a filter screen 3, which are used in conjunction with a water pump A,

[0040] Specifically, cooperate figure 1 and figure 2 As shown, the housing 1 includes a shell 11 and a bottom shell 12 , and the shell 11 and the bottom shell 12 are detachably matched by screws or buckles to form the shell 1 . The left and right sides of the housing 1 are provided with walking wheels 4, and the bottom of the housing 1 is provided with a sewage suction port 15; the filter screen 3 is arranged in the housing and covers the sewage suction port 15; There are perforations 13 and through holes 14; the through holes 14 are matched with spouts 6, and the injection direction of the spouts 6 is along the vertical upward direction of the housing 1; the perforations 13 are matched with connectors 211; in order to make the housing 1 It has strong grip when ...

Embodiment 2

[0046] In Embodiment 2, it is a further improvement of Embodiment 1. The difference between Embodiment 2 and Embodiment 1 lies in the spraying direction of the nozzle 6 and the matching relationship between the nozzle 6 and the through hole 14 on the housing 1 .

[0047] Cooperate Figure 10 to Figure 18 As shown, in the second embodiment, the nozzle 6 is rotatably fitted on the through hole 14 of the housing 1 through a bearing 61, and the injection direction of the nozzle 6 is along the oblique upward direction of the housing 1; wherein the The spraying direction of the spout 6 may form an angle greater than zero and less than or equal to forty-five degrees with the vertical upward direction of the housing 1; a limiting device for limiting the rotation angle of the spout 6 is provided between the spout 6 and the through hole 14, The limiting device includes a rotation clamping point 62 on the other side of the nozzle 6 opposite to one side of the injection direction of the n...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap