A speed reduction mechanism for a barbeque turning device stabilizing and increasing torque with five phases of speed reduction

A technology of a reduction mechanism and a rotating device, which is applied in the direction of transmission, gear transmission, mechanical equipment, etc., can solve the problems of shaft deviation, shortened service life of the motor 143, and noise generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

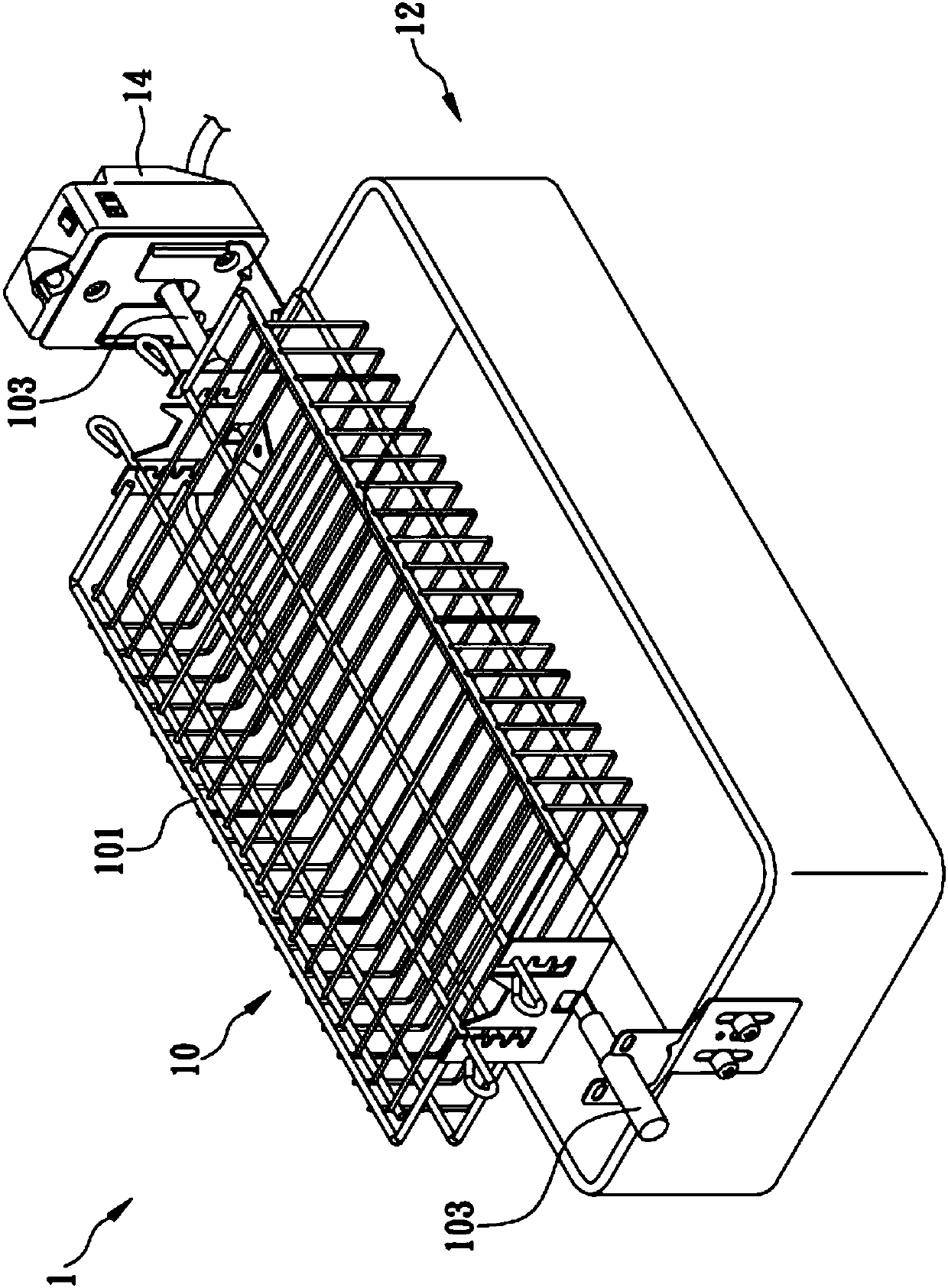

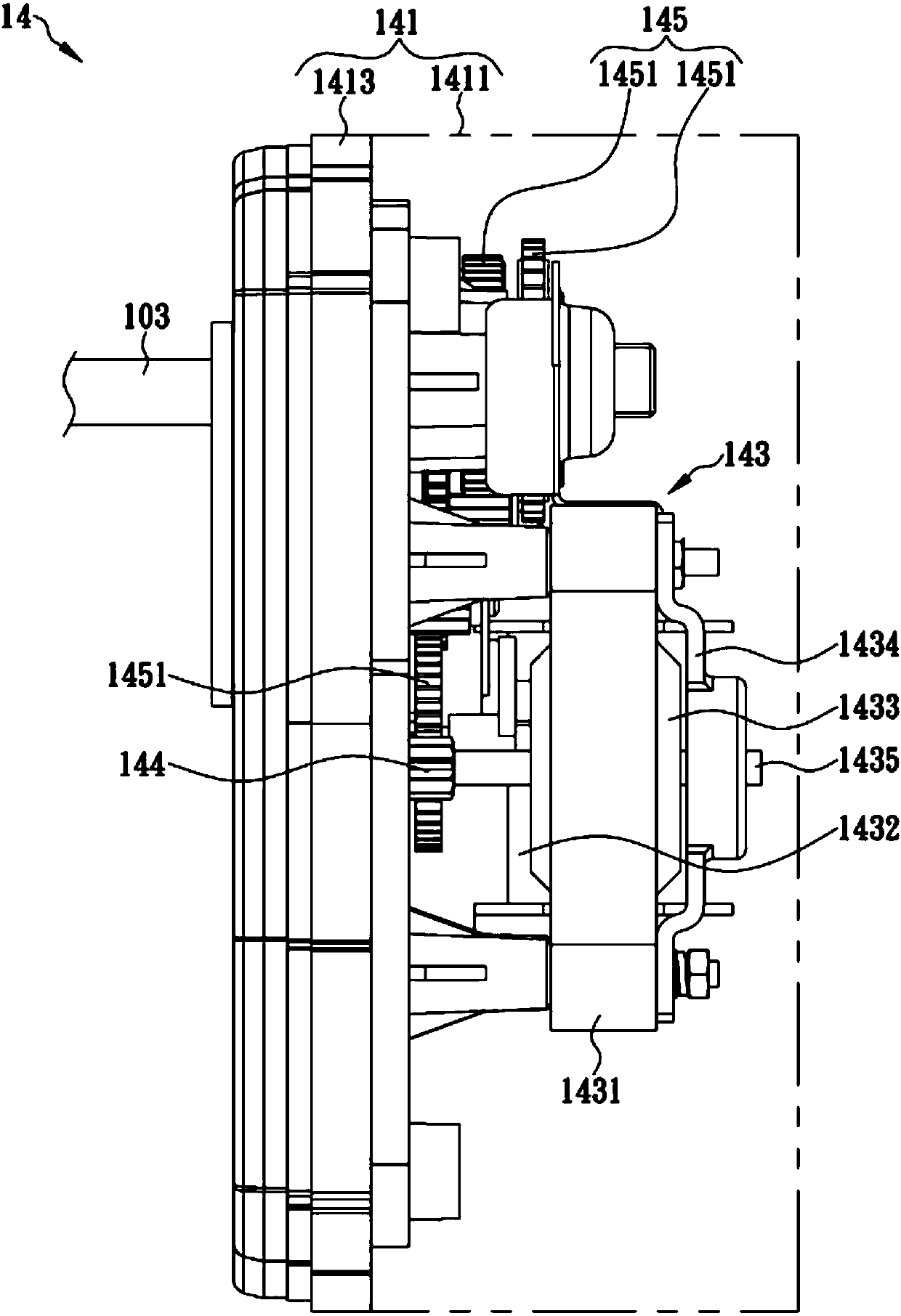

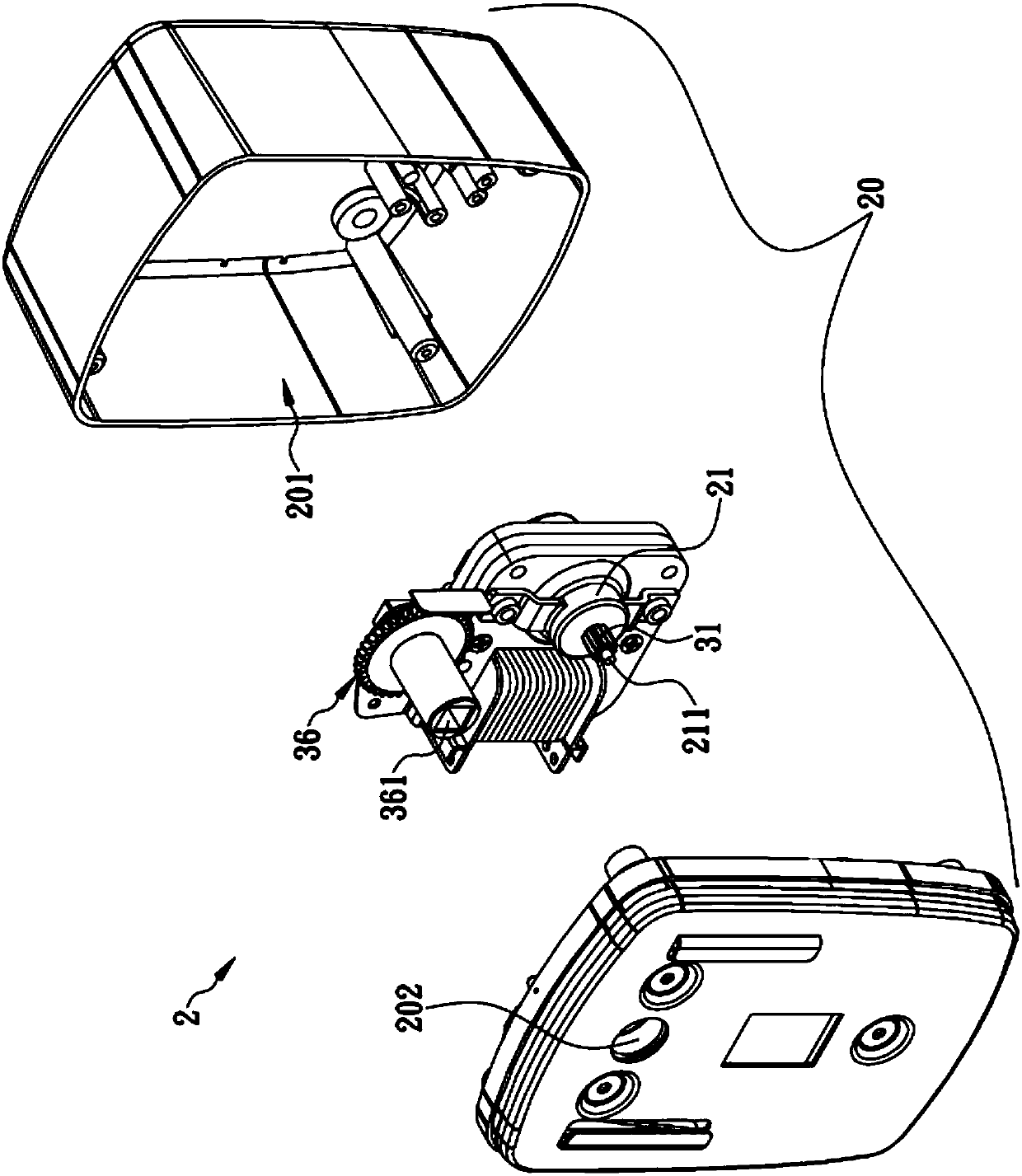

[0061] The present invention is a deceleration mechanism of a rotating device for barbecue with five-stage deceleration, stability and increased torque, please refer to image 3 and Figure 4 As shown, the rotating device 2 for barbecue includes a housing 20, a motor 21 and the speed reduction mechanism 30, wherein the housing 20 is installed on the outer edge of a barbecue oven, and a housing space 201 is provided inside it. A through hole 202 is provided on the side facing the barbecue stove, the through hole 202 communicates with the accommodating space 201, the motor 21 is installed and fixed in the accommodating space 201, the speed reduction mechanism 30 is positioned in the accommodating space 201, And located bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com