Rotating mechanism and excavating machine

A technology of slewing mechanism and roadheading machine, which is applied in the direction of slitting machinery, driving device, mining equipment, etc. It can solve the problems of uncoordinated roadheading machines, large torque changes, inconvenient installation and maintenance, etc., and achieve small layout space and activity space , The rotation torque is stable, and the effect of easy disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be pointed out that the description and sequence of specific structures in this section are only descriptions of specific embodiments, and should not be considered as limiting the protection scope of the present invention.

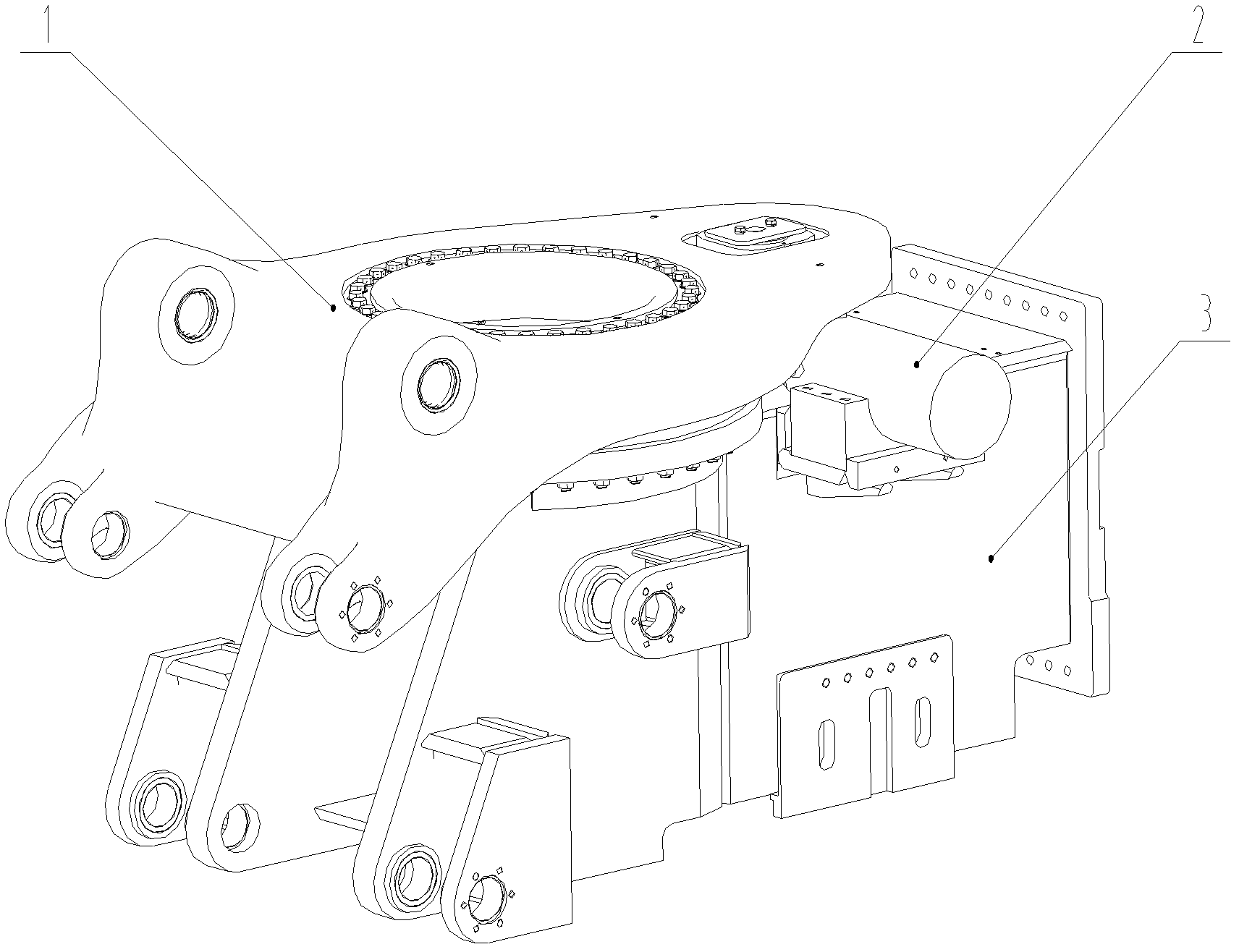

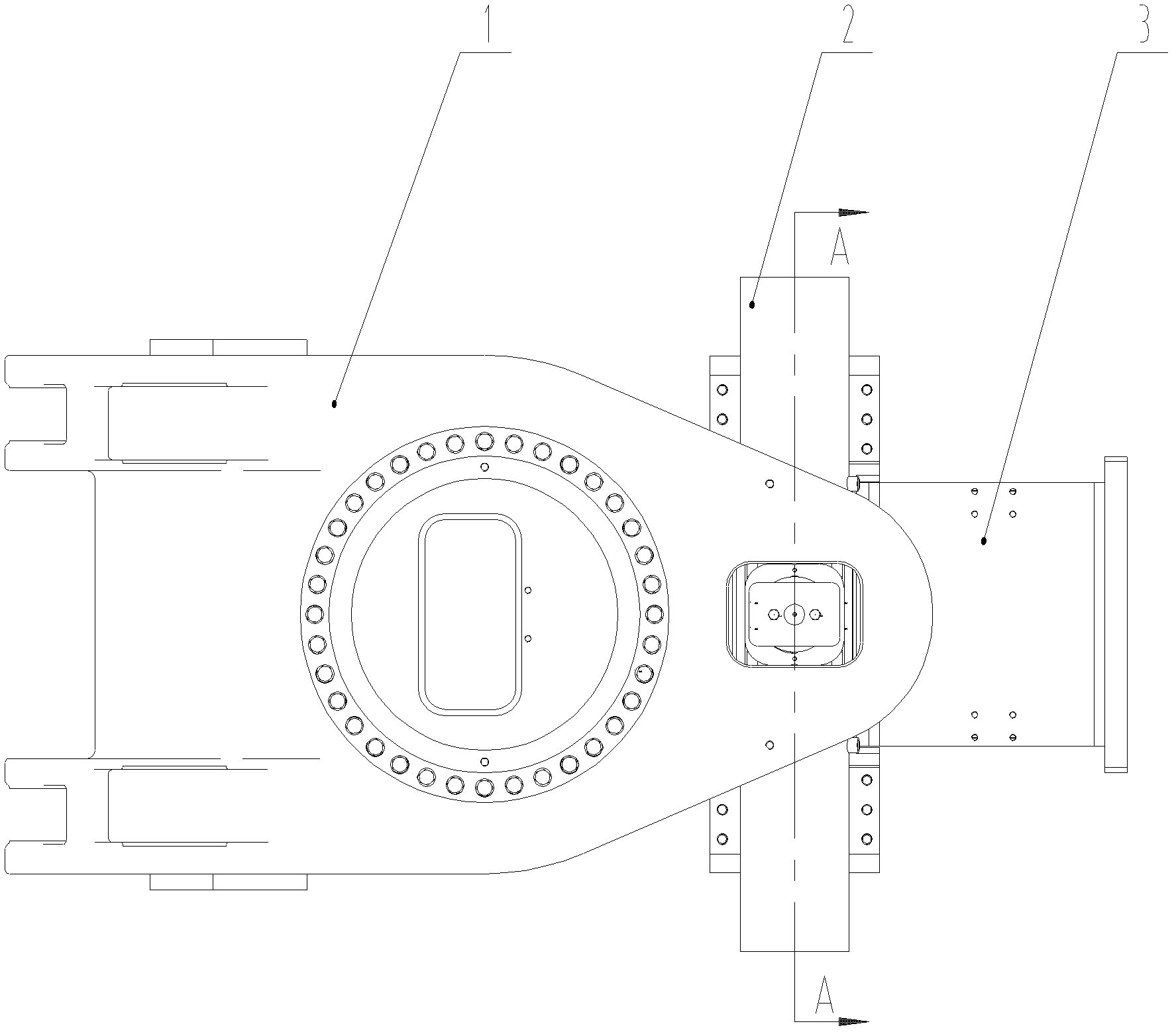

[0026] Please refer to Figure 2 to Figure 7 ,in, figure 2 It is a schematic structural diagram of a rotary mechanism provided by an embodiment of the present invention, image 3 for figure 2 top view of Figure 4 It is a schematic structural diagram of the turntable in the embodiment of the present invention, Figure 5 It is a schematic structural view of the oil cylinder in the embodiment of the present invention, Figure 6 It is a schematic structural diagram of the body in the embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com