DC electric motor

A DC motor, magnetic pole technology, applied in the manufacture of motor generators, motor components, DC commutators, etc., can solve the problems of uneven tension, inability to obtain torque performance, uneven coil winding, etc., to achieve uniform winding, reduce Cogging torque and the effect of approximately uniform length of transition line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

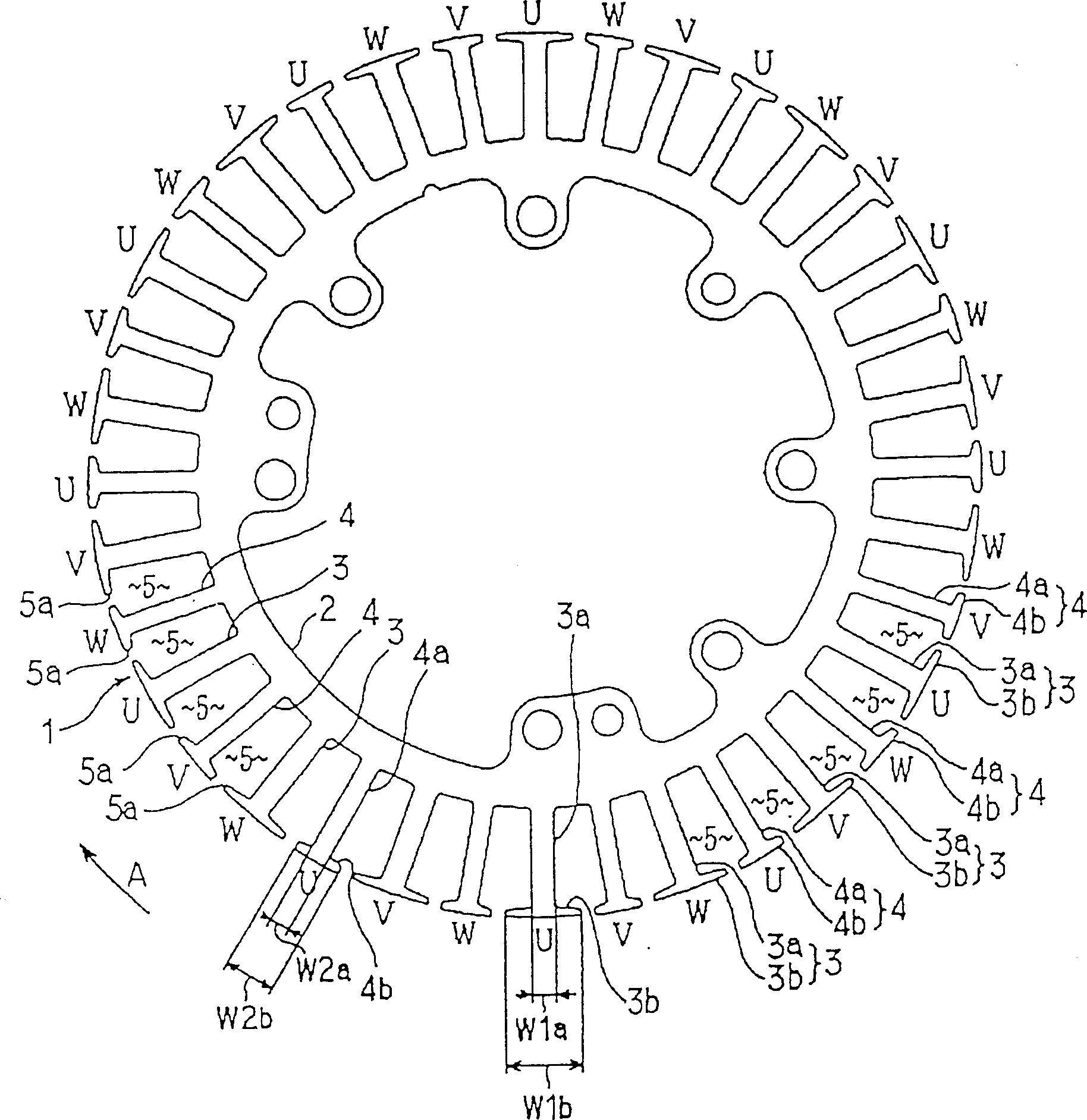

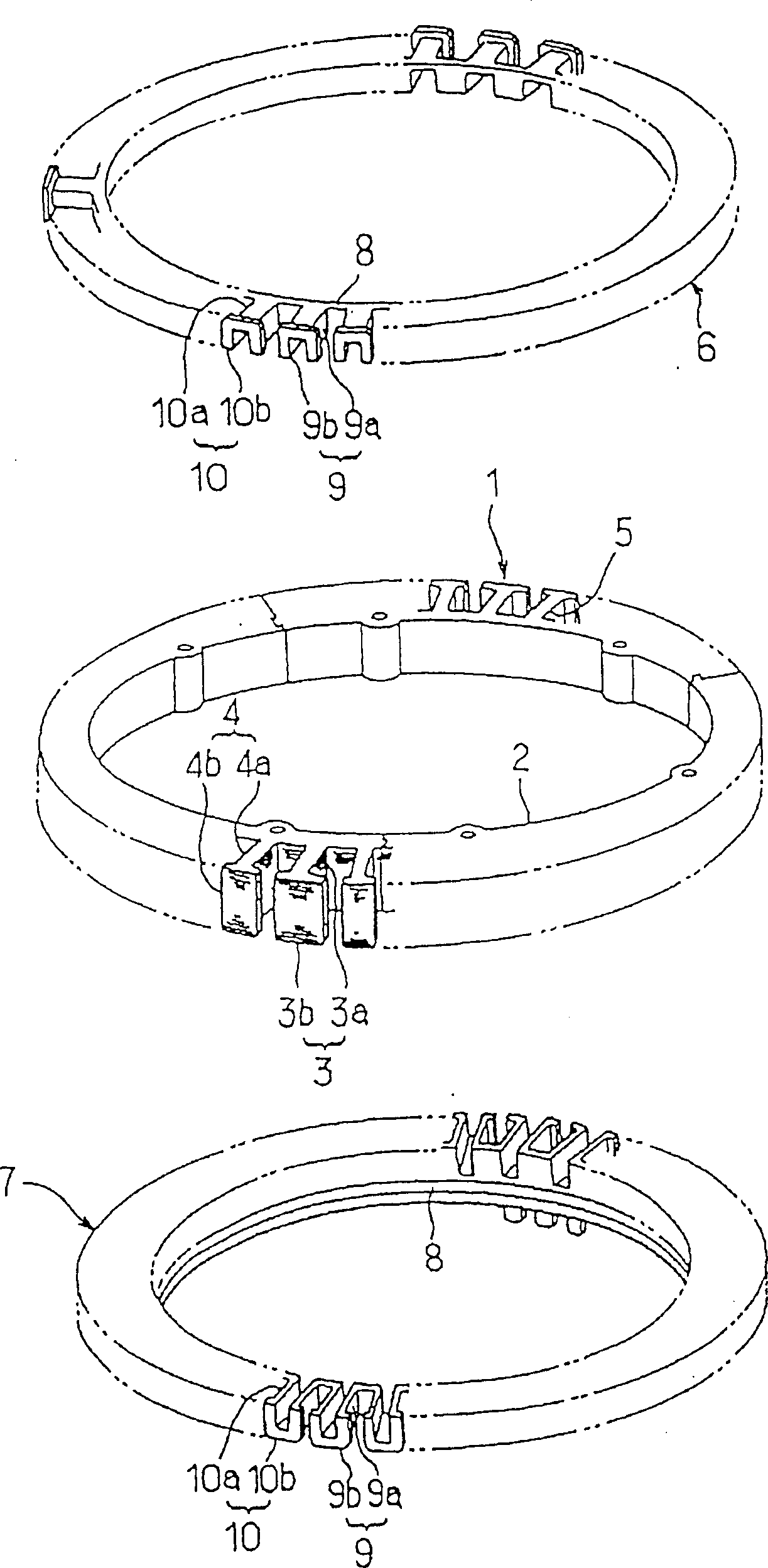

[0038] Next, an embodiment of the present invention will be described with reference to the drawings. This embodiment adopts the present invention as an outer rotor type 3-phase 36-pole DC brushless motor for driving a washing machine pulsator and a washing tub.

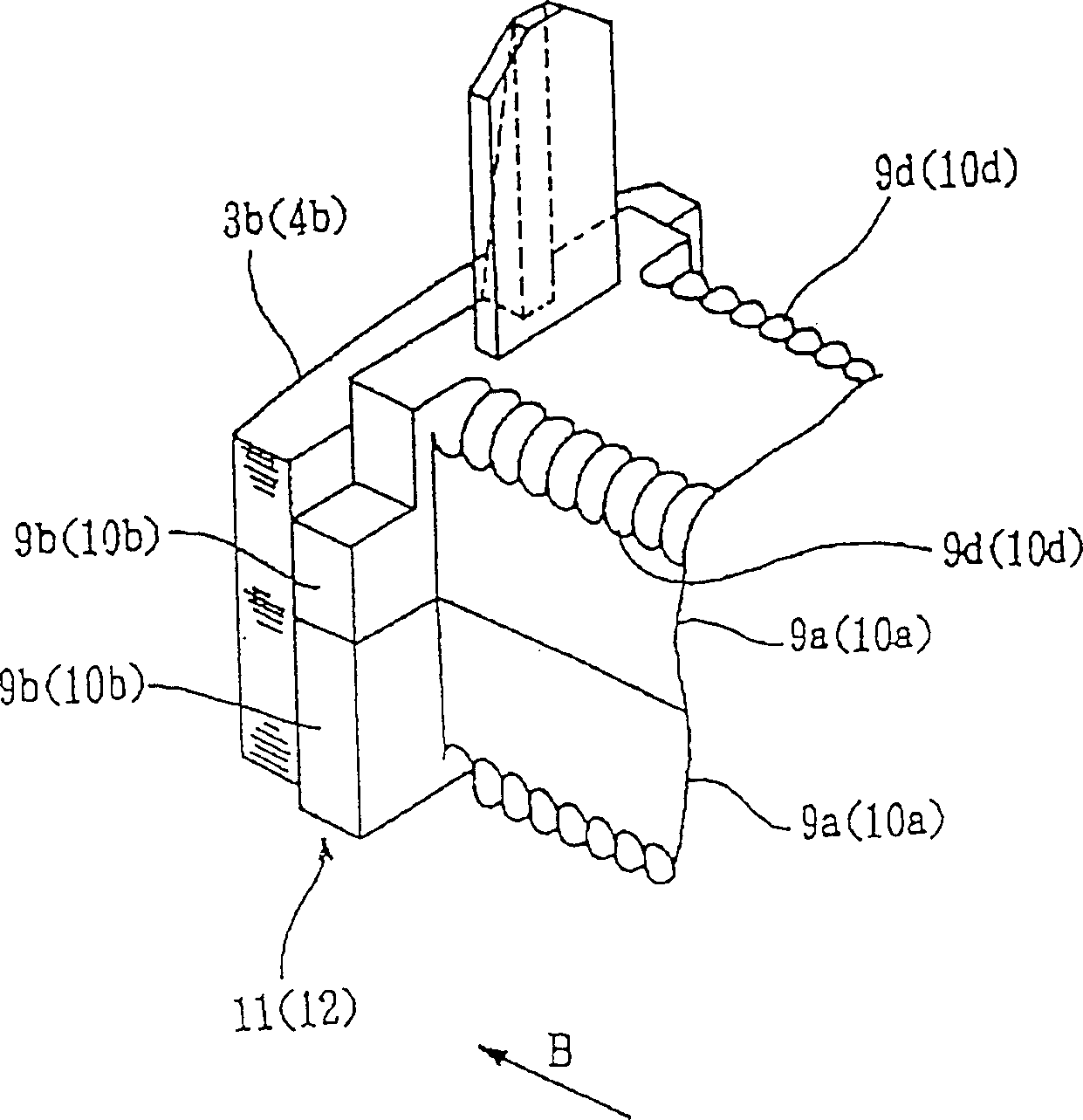

[0039] First, in figure 1Among them, the stator core 1 is composed of a substantially cylindrical inner yoke 2, 18 first T-shaped magnetic poles 3 radially extending from the inner yoke 2, and 18 second T-shaped magnetic poles 4 radially extending from the inner yoke 2 The configuration is such that the first T-shaped magnetic poles 3 and the second T-shaped magnetic poles 4 are alternately arranged at equal pitches (=10°) along the circumferential direction.

[0040] Each first T-shaped magnetic pole 3 is made up of a square column-shaped coil winding portion 3a and a magnetic pole portion 3b protruding from the side of the coil winding portion 3a in the circumferential direction. The circumferential width dimensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com