Annular seal space for neutron static high-pressure experiments

A sealed chamber and high-pressure technology, which is applied to the use of wave/particle radiation for material analysis, measuring devices, instruments, etc., can solve the problems of environmental and experimental personnel hazards, leakage of toxic and harmful substances, and inability to play a sealing role. Convenient, fast and convenient assembly, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

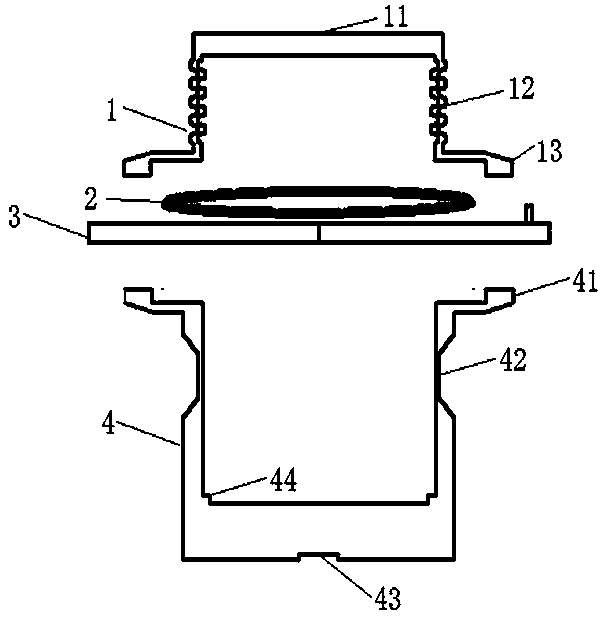

[0013] figure 1 It is a schematic diagram of the sealed chamber of the neutron static high pressure experiment of the present invention. As shown in the figure, the sealed cavity of the neutron static high pressure experiment of the present invention includes a sealed cavity cover 1 , a sealing gasket 2 , a clip 3 and a sealed cavity bottom 4 . The sealing chamber cover 1 is cylindrical, and the inside is cylindrical, including the sealing chamber top plate 11, the bellows 12 and the upper flange opening 13, the sealing chamber top plate 11 and the upper flange opening 13 are all stainless steel, the sealing chamber top plate 11 and the upper The flange ports 13 are respectively welded to the upper and lower ends of the bellows 12, the upper flange port 13 is the opening end of the sealing chamber cover 1, the sealing chamber top plate 11 is the closed end of the seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com