Overhead distribution line

A technology of distribution lines and wires, which is applied in the field of overhead distribution lines, can solve problems such as poor stability of lightning arresters or lightning protection insulators, threats to personal safety, and high labor costs, so as to achieve stable and reliable electrical performance, simplify line structure, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

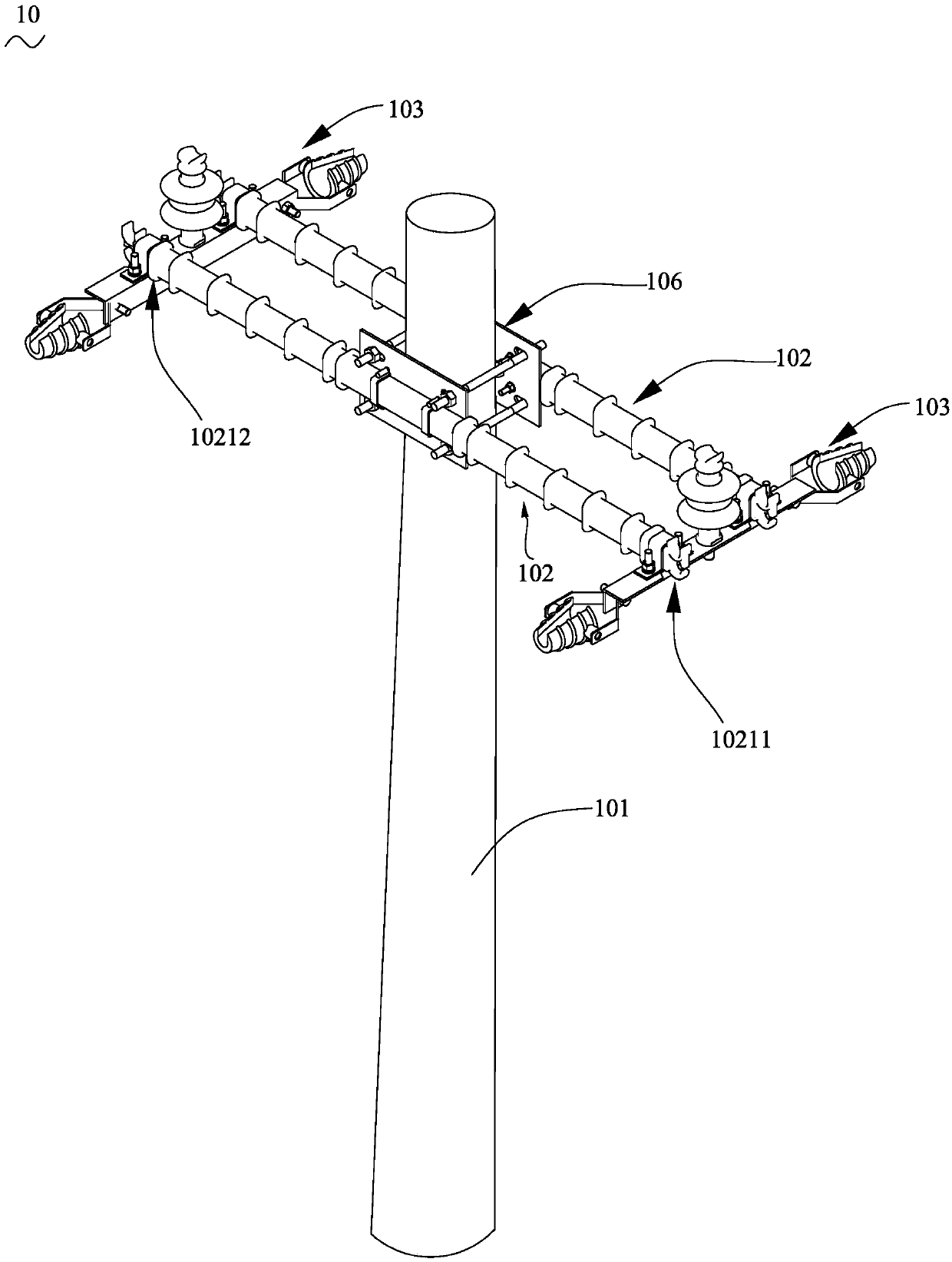

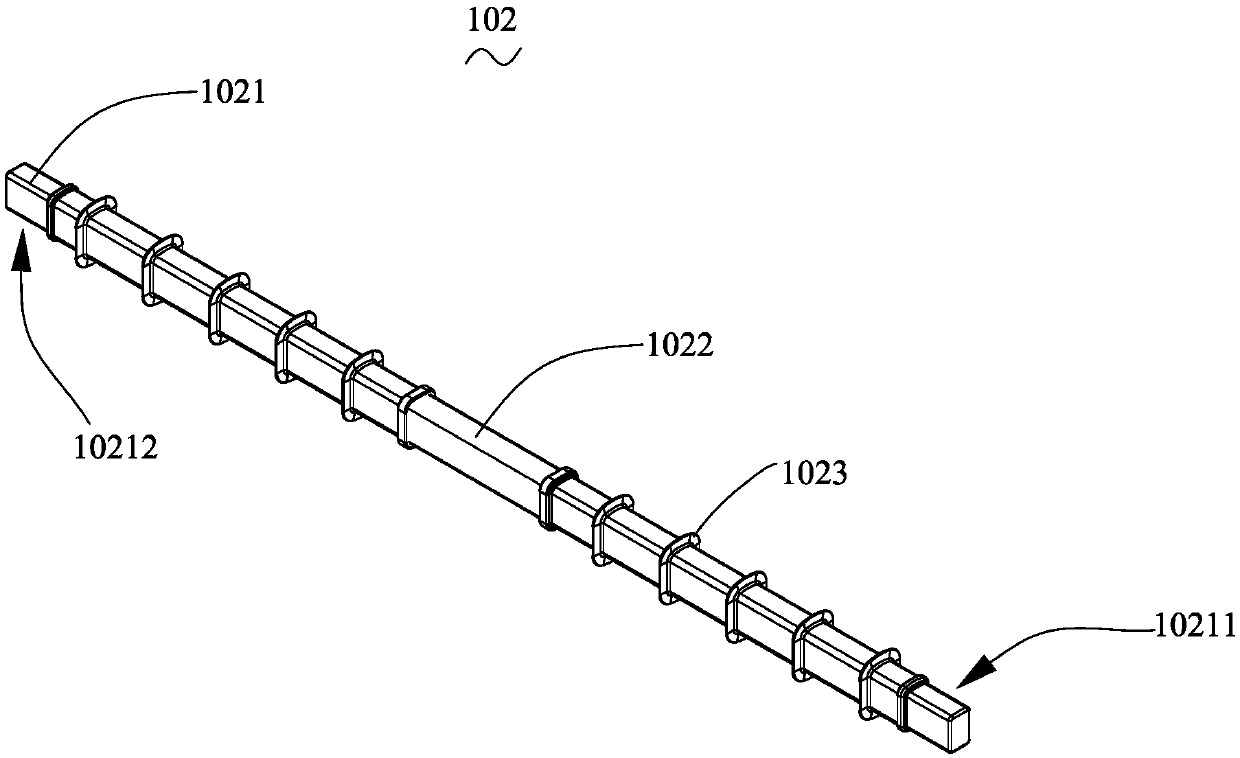

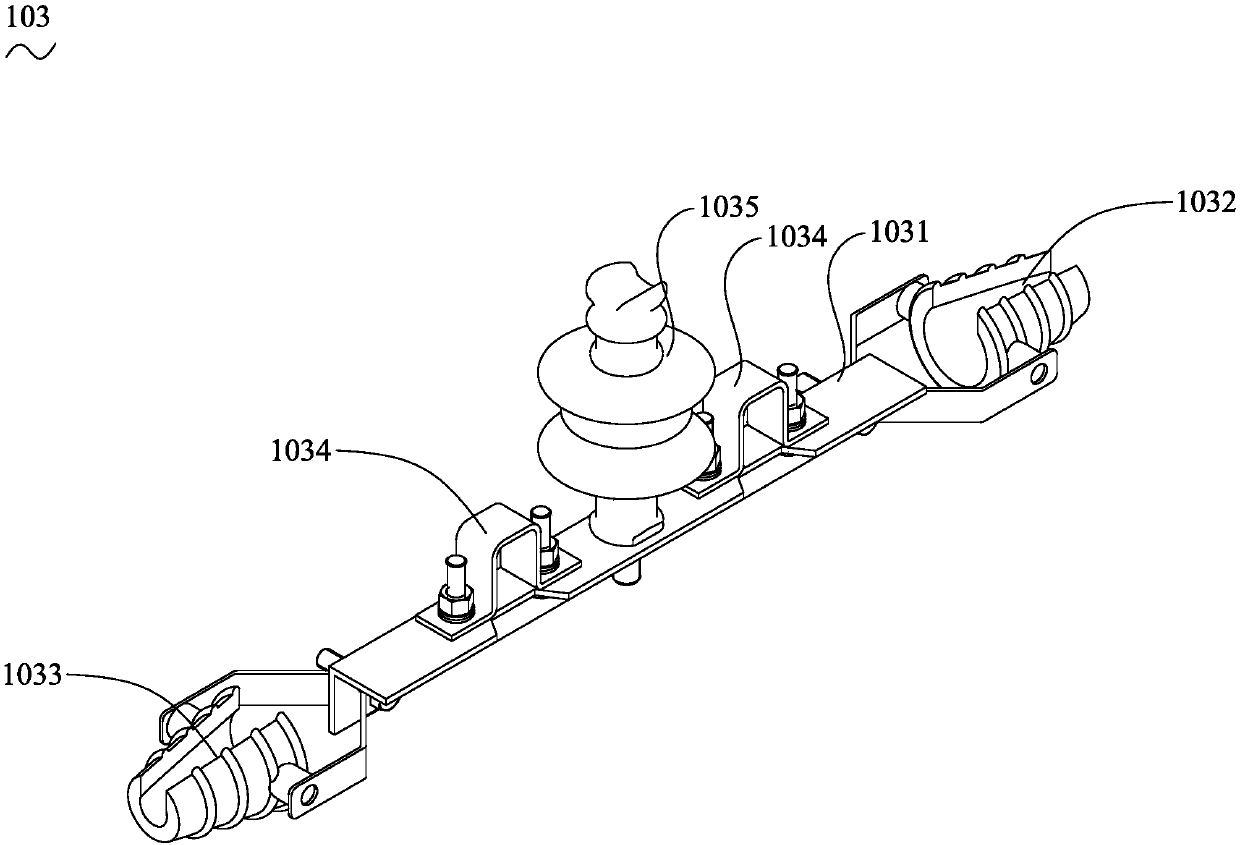

[0043] Please refer to Figure 1-Figure 6 . Such as figure 1 As shown, the overhead power distribution line 10 includes a tension rod 101, two composite cross arms 102 and a tension fixture 103; the middle part of the composite cross arms 102 is horizontally fixed on the tension rod 101, and the ends of the composite cross arms 102 are connected There is a tension-resistant fixing piece 103, which connects the two composite cross-arms 102 into one, and the tension-resistant fixing piece 103 is used for fixing the wire.

[0044] Specifically, the middle part of the composite cross-arm 102 is horizontally fixed on the tension bar 101, so that both ends 10211 / 10212 of the composite cross-arm 102 are free ends, and the middle part here does not necessarily refer to the middle of the composite cross-arm 102, It refers to other regions except the two ends 10211 / 10212. The advantage of such fixing is that a composite cross arm 102 can be used to realize the fixing of two-phase con...

Embodiment approach 2

[0066] Such as Figure 7 As shown, the overhead power distribution line 20 of this embodiment includes: a tension rod 201, two composite cross arms 202 and a tension fixing member 203; the middle part of the composite cross arm 202 is horizontally fixed on the tension rod 201, and the composite cross arm 202 The end of each is connected with a tension-resistant fixing piece 203, which connects the two composite cross-arms 202 into one, and the tension-resistant fixing piece 203 is used to fix the wire.

[0067] In addition, the overhead power distribution line 20 also includes two top phase cross arms 204, the top phase cross arms 204 are vertically fixed on the top of the tension rod 201 away from the ground, and the ends of the top phase cross arms 204 are connected with top phase tension anchors. 205, the top phase tension fixing piece 205 connects the two top phase cross arms 204 into one, and the top phase tension fixing piece 205 is used to fix the wire.

[0068] Specif...

Embodiment approach 3

[0074] Please refer to Figure 10 with Figure 11 , the overhead power distribution line 30 of the present embodiment includes: a tension rod 301, two composite cross arms 302 and a tension fixture 303; the middle part of the composite cross arm 302 is horizontally fixed on the tension rod 301, and the end The upper part is connected with a tension-resistant fixing piece 303, which connects the two composite cross-arms 302 into one, and the tension-resistant fixing piece 303 is used to fix the wire.

[0075] The overhead distribution line 30 also includes two top phase cross arms 304, the top phase cross arms 304 are vertically fixed on the top of the tension rod 301 away from the ground, and the ends of the top phase cross arms 304 are connected with a top phase tension fixture 305 , the top-phase tension-resistant fixing member 305 connects the two top-phase cross-arms 304 into one, and the top-phase tension-resistant fixing member 305 is used to fix the wire.

[0076]In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com