Screening device for the generative manufacturing of components

A generative and screening technology, applied in the direction of additive manufacturing, processing manufacturing, manufacturing tools, etc., can solve problems such as prolonging preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

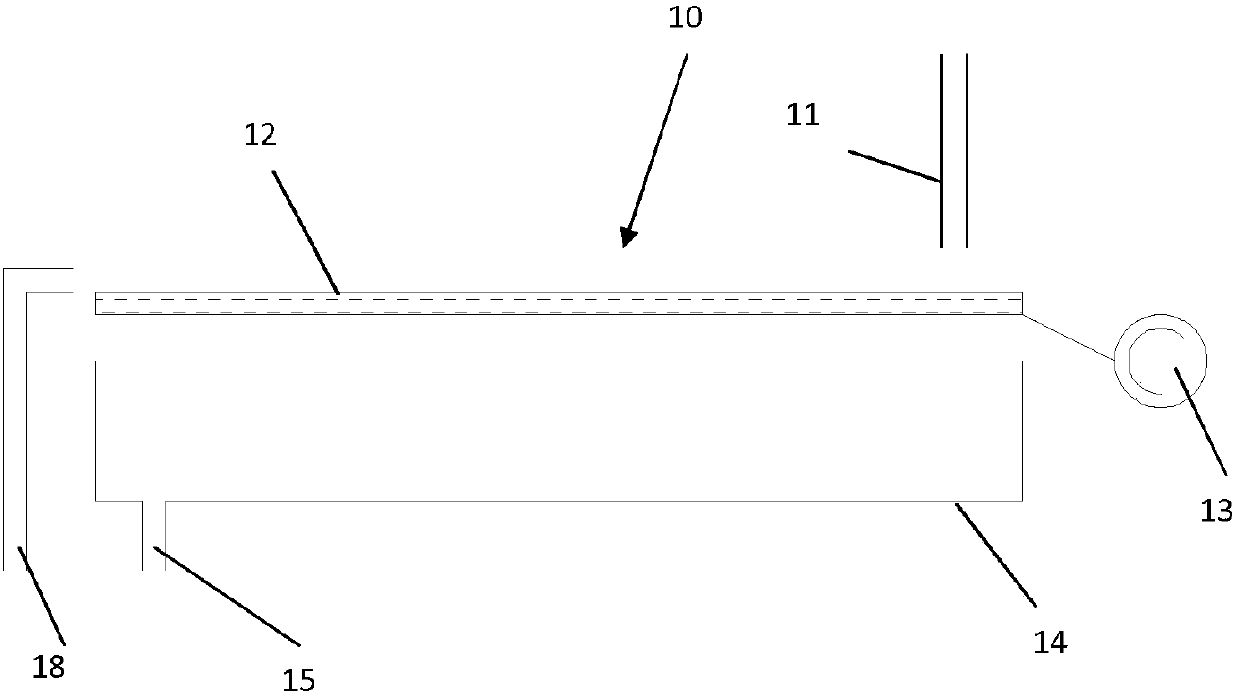

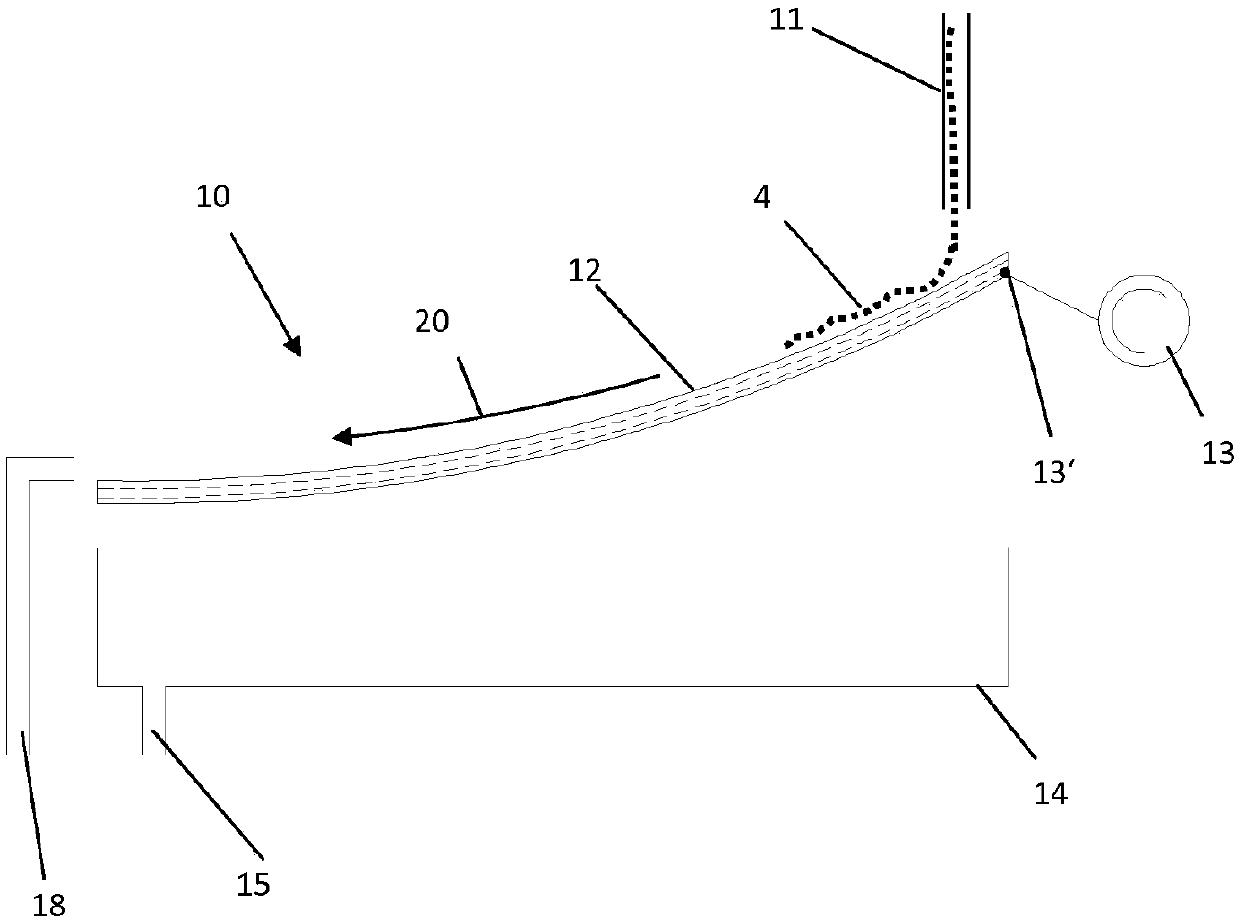

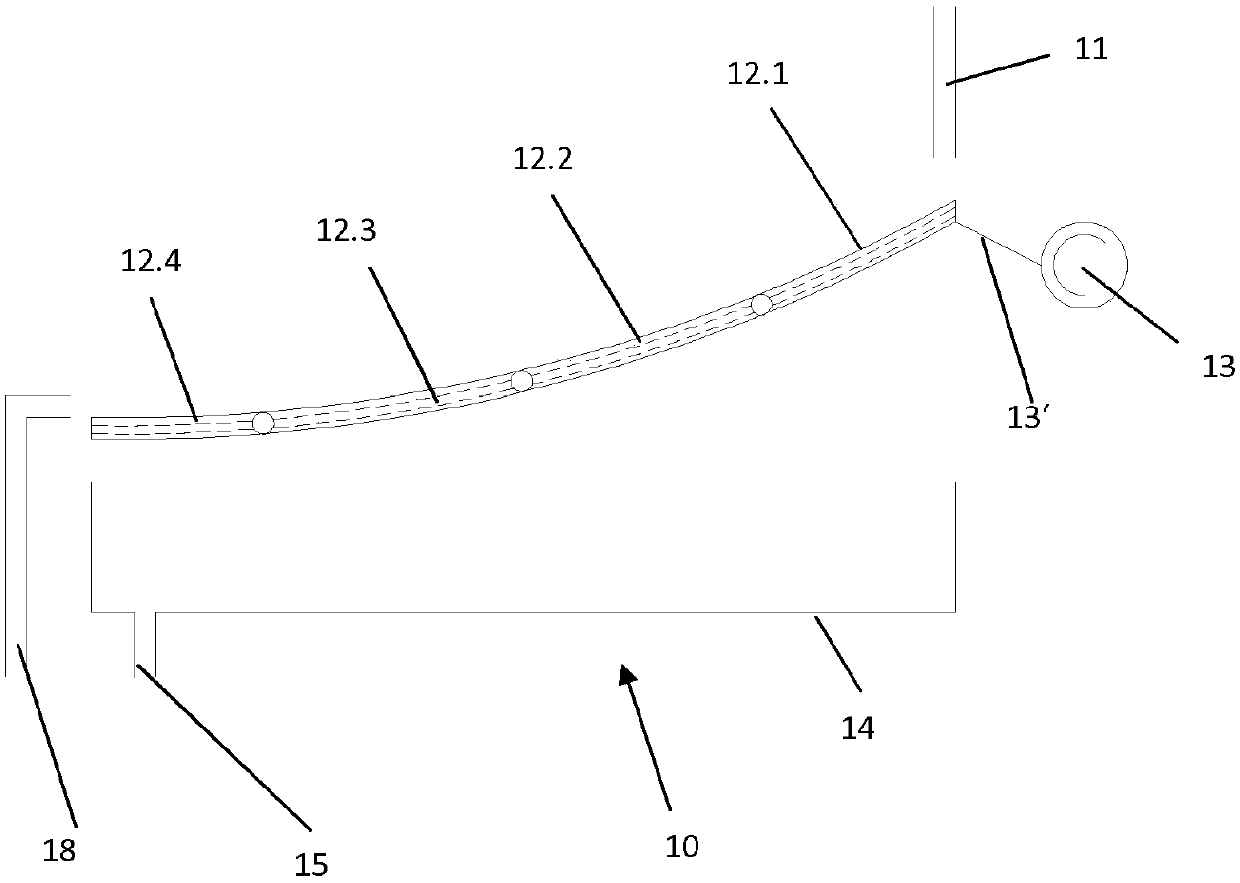

[0016] See first illustration 8 of the accompanying drawings.

[0017] exist Figure 8 A device 1 for producing a component 2 by successively solidifying individual layers 3 of a powdery curable construction material 4 is schematically shown in , wherein the construction material 4 is melted or melted by laser radiation 5 and is cooled are then connected into solid components. Such a device 1 comprises a coating device 6 for applying a powder layer 3 onto a preferably height-adjustable carrier 7, a metering device 8 for supplying the coating device with building material 4, a An overflow container 9 for unneeded construction material 4 and a sieve device 10, which is designed according to FIG. feature. In the prior art, the sieving device 10 comprises a powder inlet 11, whereby excess building material 4 from the overflow container 9 is fed into the sieving process. The sieving material consisting of particles of different sizes falls onto the sieve 12 of the sifting devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com