Curler hooked to staggered-type multi-layer front fly fold folding sliding shuttle for belt loop

A shuttle hooking and interlacing technology, applied in the field of curlers, can solve the problems of curling and folding widening deviation, looseness, and affecting the width of trousers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

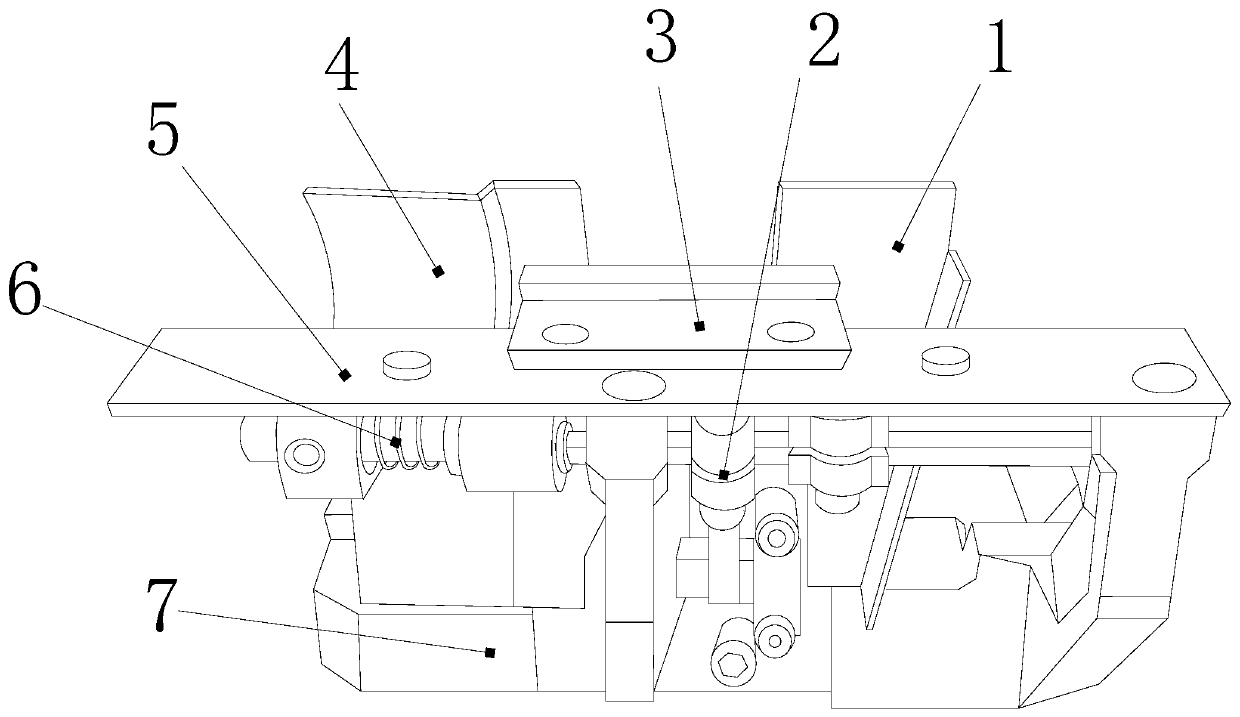

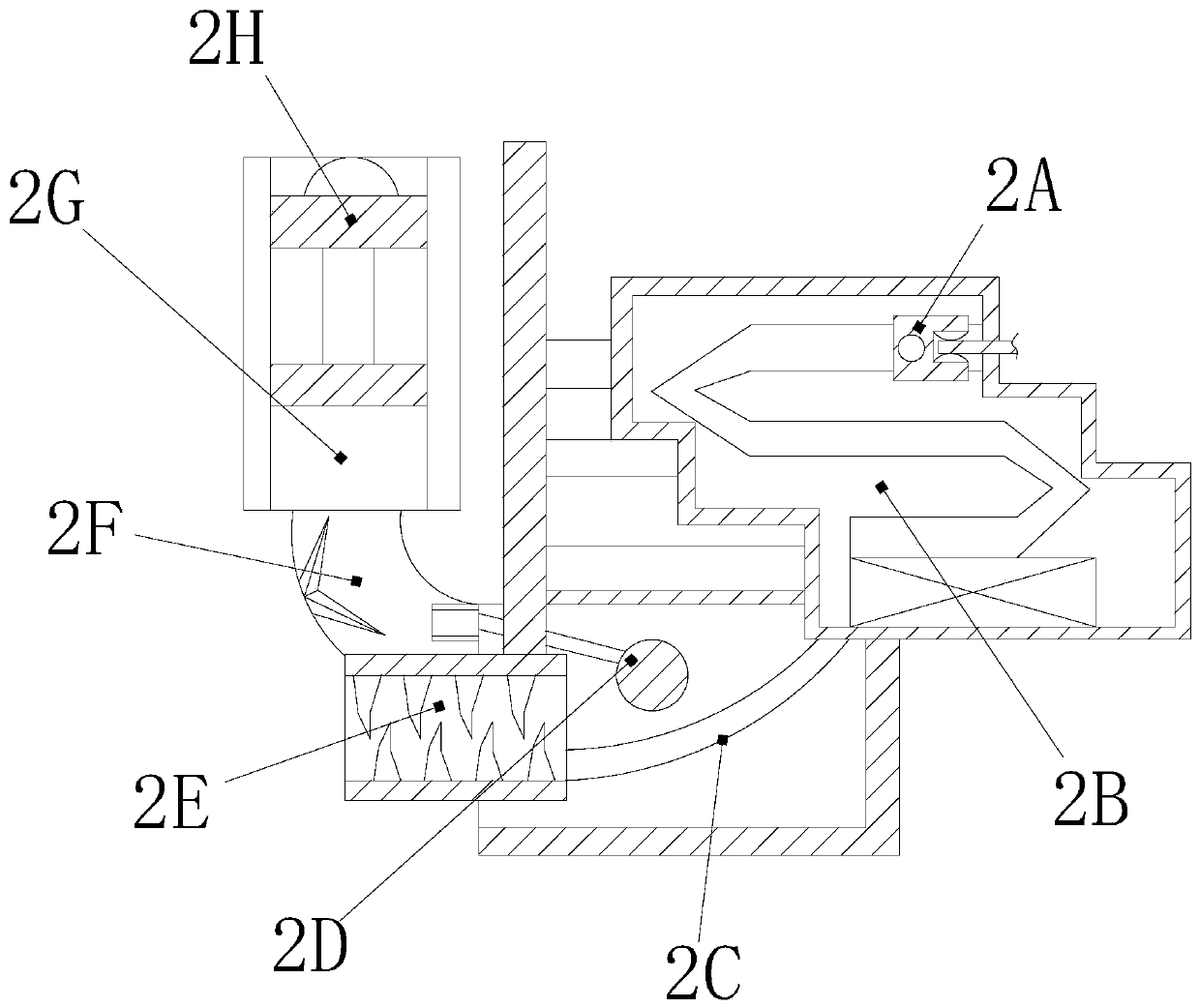

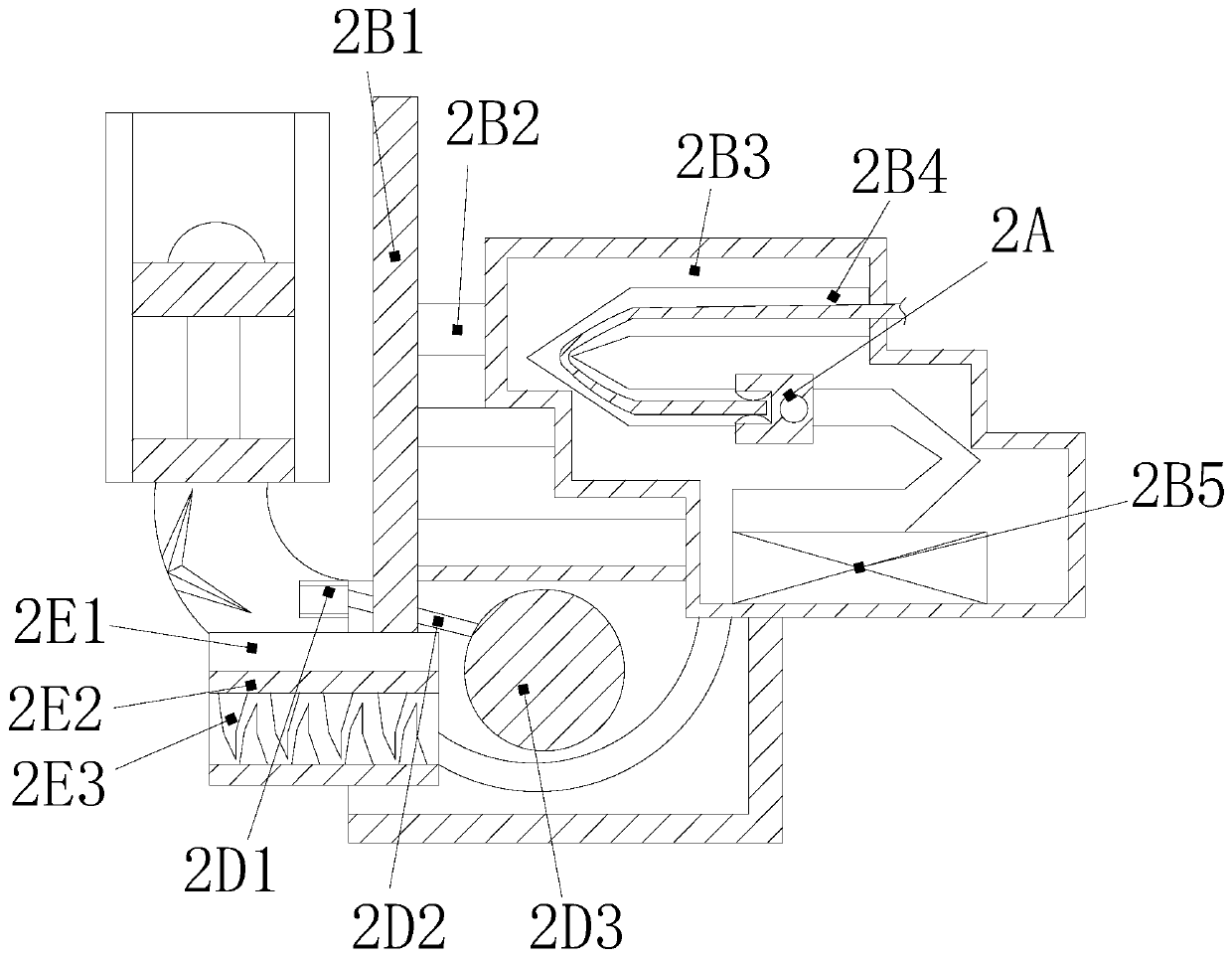

[0032] see Figure 1-Figure 7 , the present invention provides a trousers staggered staggered multi-layer placket folded shuttle hook crimping device, the structure of which includes: a clip hem plate 1, a shuttle hooking device 2, a press-embedded clamping plate 3, a curved arc Vertical plate 4, smooth slat 5, roller spring rod 6, grid groove base block 7, the shuttle hooking device 2 is inserted under the bottom of the middle section of the smooth slat 5, and the press-embedded clamping plate 3 is close to On the top surface of the middle section of the smooth slat 5 and on the same horizontal plane, the curved vertical plate 4 and the buckle flange 1 are installed on the left and right sides of the rear end of the smooth slat 5 and the grid gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com