A multi-segment splicing repair process and pipeline repair structure

A pipeline repair and pipeline technology, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve problems such as increased construction costs, difficulty in rolling and molding, buckling damage, etc., and achieves easy welding operations and welding effects The effect of stabilizing and reducing technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with drawings and embodiments.

[0033] (1) Segment the pipeline to be repaired at intervals of tens of meters or hundreds of meters in the axial direction, and dig a working pit; for each section of pipeline, repeat steps (2) to (9);

[0034] (2) To clean the inner wall of the pipeline, the inner wall of the pipeline after pretreatment is required to be clean, smooth, and there is no obvious protrusion in the cross section;

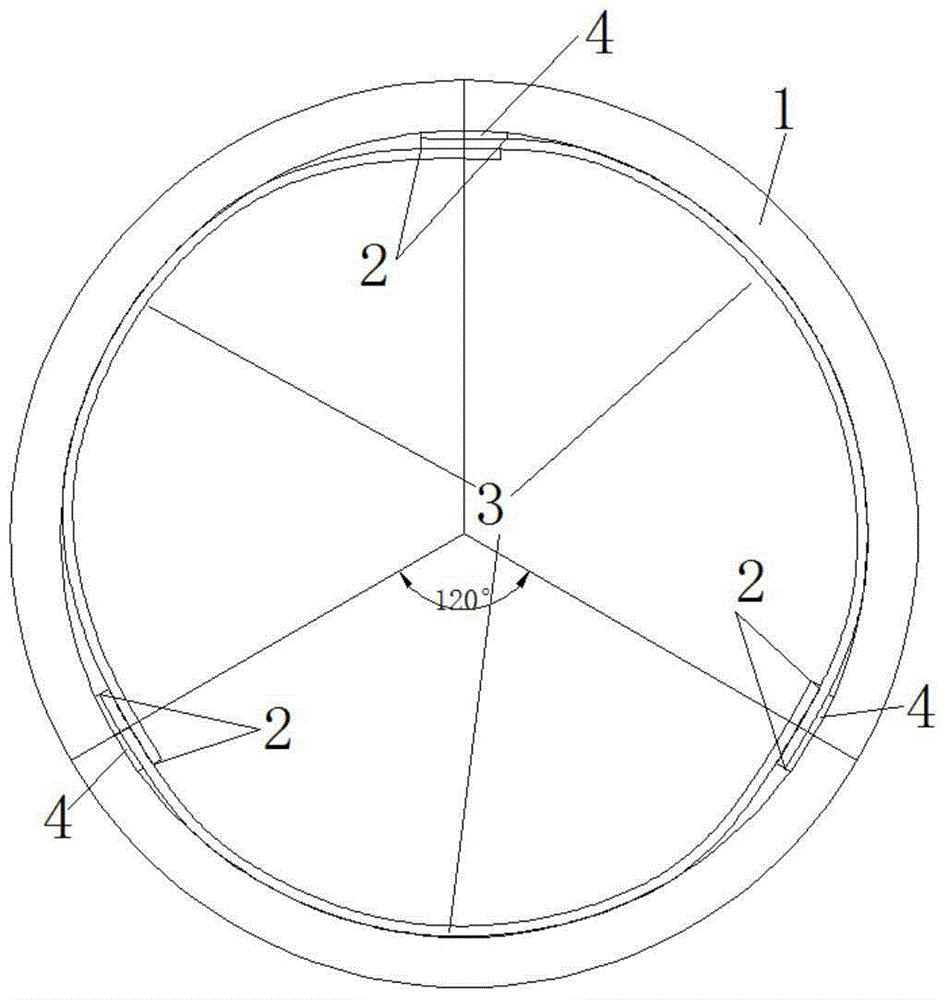

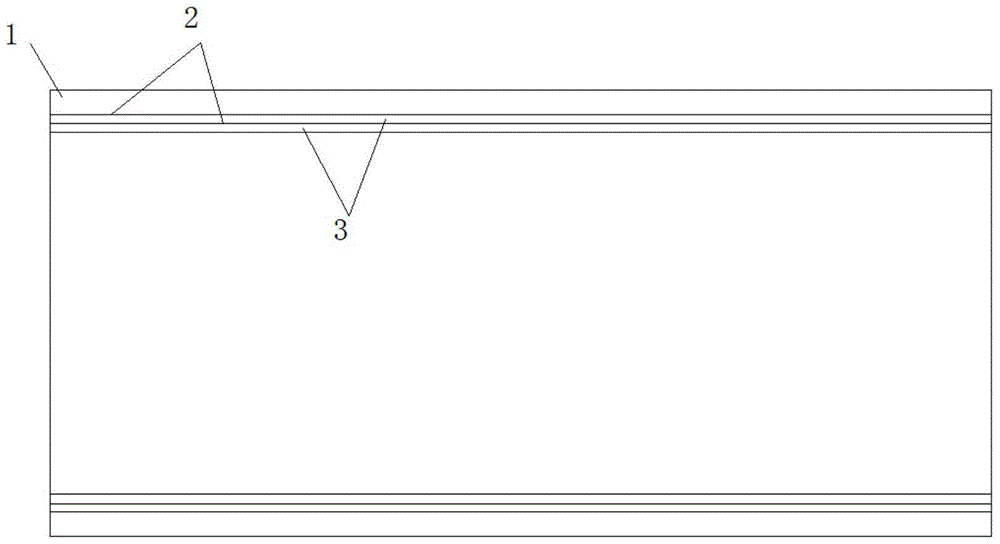

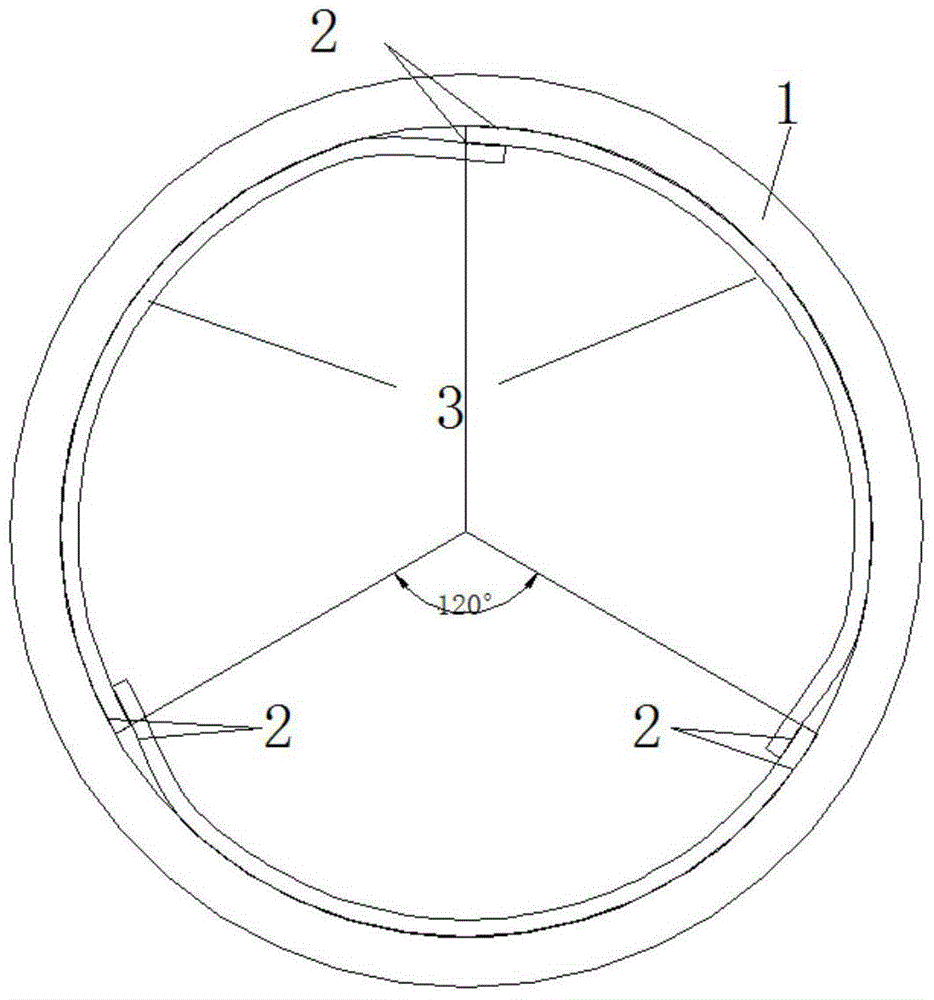

[0035] (3) Accurately measure the geometric profile of the cross-section of the pipeline along the axial direction, determine the curvature of the inner wall of the cross-section, and divide the pipeline along the circumference of the pipeline according to the curvature of the inner wall. In order to facilitate the quality control of large-scale projects, each division can be numbered;

[0036] (4) For pipelines made of non-steel materials, thin-walled steel plates are fixed axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com