Bending device of stainless steel clamp band for automobile exhaust system

A technology of automobile exhaust system and stainless steel card, which is applied in metal processing equipment and other directions, can solve the problem of single arc of bending mold, and achieve the effect of uniform bending arc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

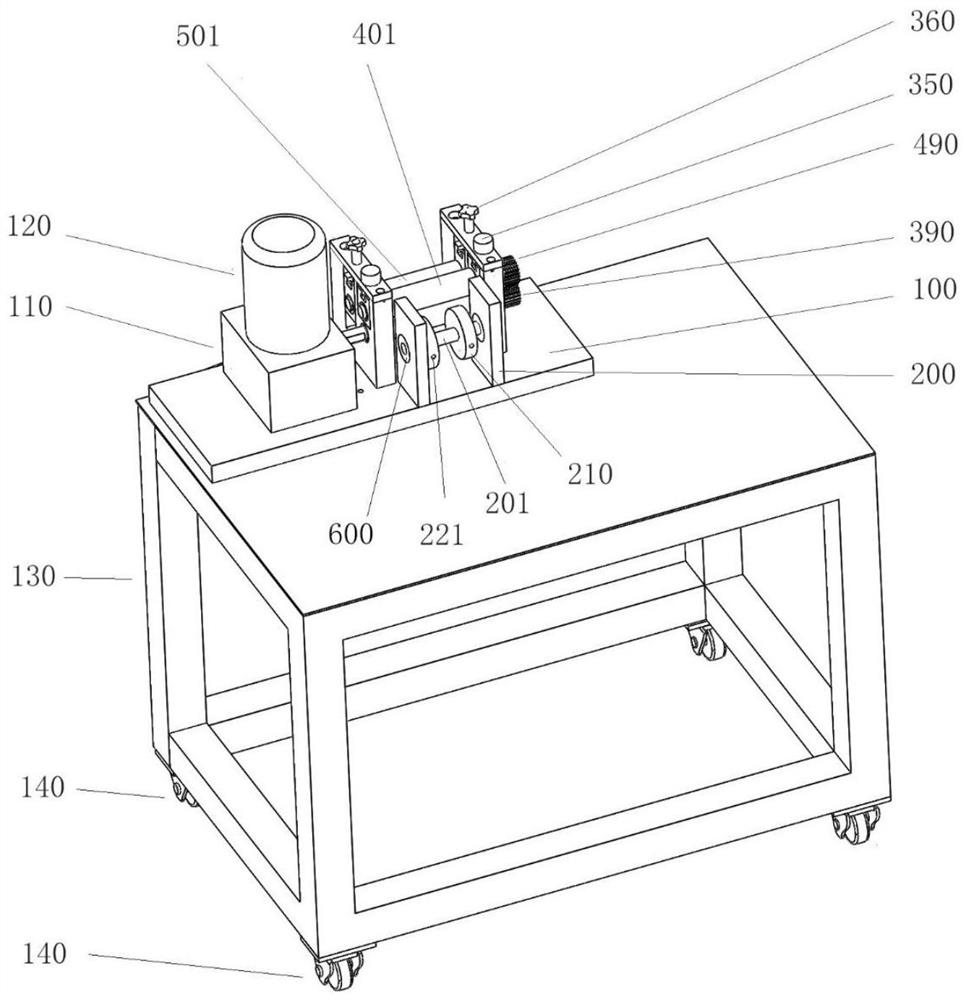

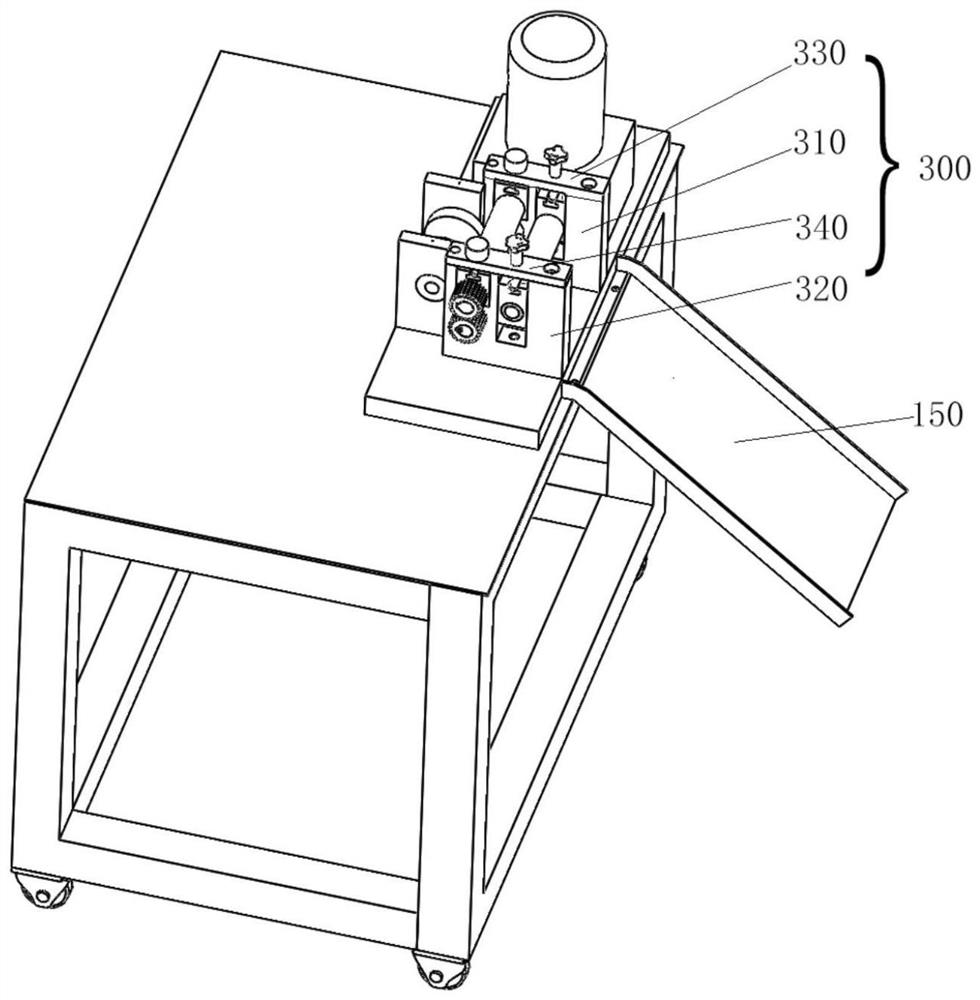

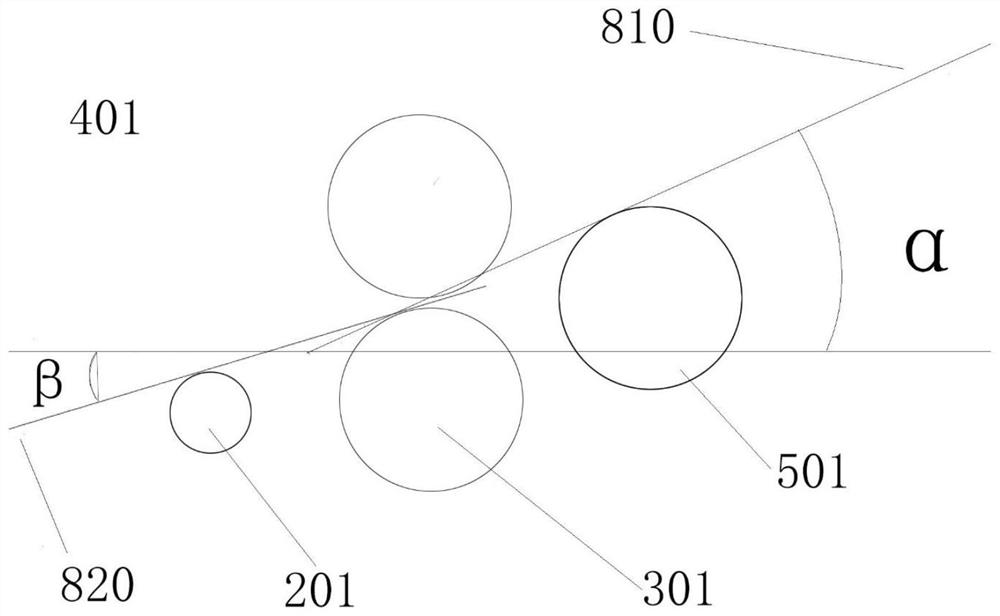

[0044] Example: as Figure 1 to Figure 8As shown in the figure, a rounding device for stainless steel clamp belts for automobile exhaust systems includes a workbench 100. On the workbench 100, a guide roller bracket 200, a driving roller bracket 300, and a driving roller bracket 300 are fixedly arranged in sequence from front to back. The driving roller 301, the driven roller support 400, and the forming roller support 500 are arranged in sequence from front to back; Rotation setting; driven roller support 400 is rotatably provided with driven roller 401, forming roller support 500 is rotatably provided with forming roller 501, guide roller support 200 is rotatably provided with guide roller 201, guide roller 201, driving roller 301, and The axes of the driving roller 401 and the forming roller 501 are parallel to each other, the axis of the driving roller 301 and the axis of the driven roller 401 are on a vertical plane, the axis of the driving roller 301 is below the axis of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com