An egg-shaped pressure shell manufacturing device and manufacturing method

A technology for manufacturing devices and pressure-resistant shells, which is applied in the field of pressure-resistant device manufacturing, and can solve the problem of destroying the surface quality of the radius of curvature at the bottom of the egg-shaped pressure-resistant shell, affecting the surface curvature and thickness distribution of the egg-shaped pressure-resistant shell, and the large end of the egg-shaped curve Incomplete symmetry with the small end, etc., to achieve the effect of smooth surface, uniform curvature, and high processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

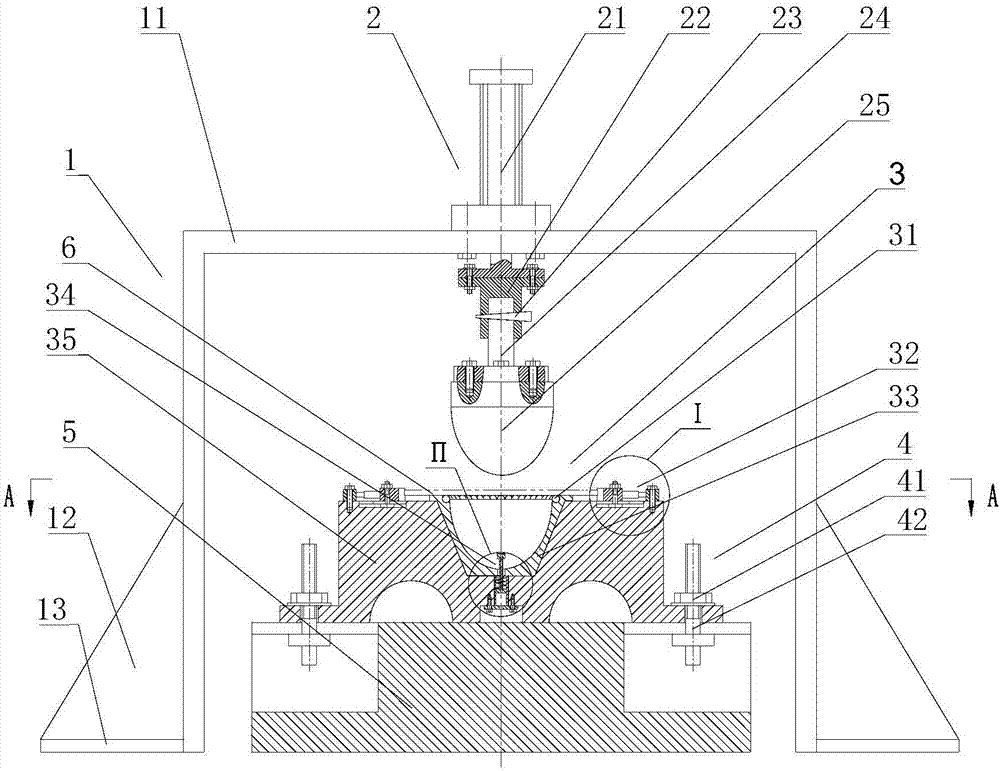

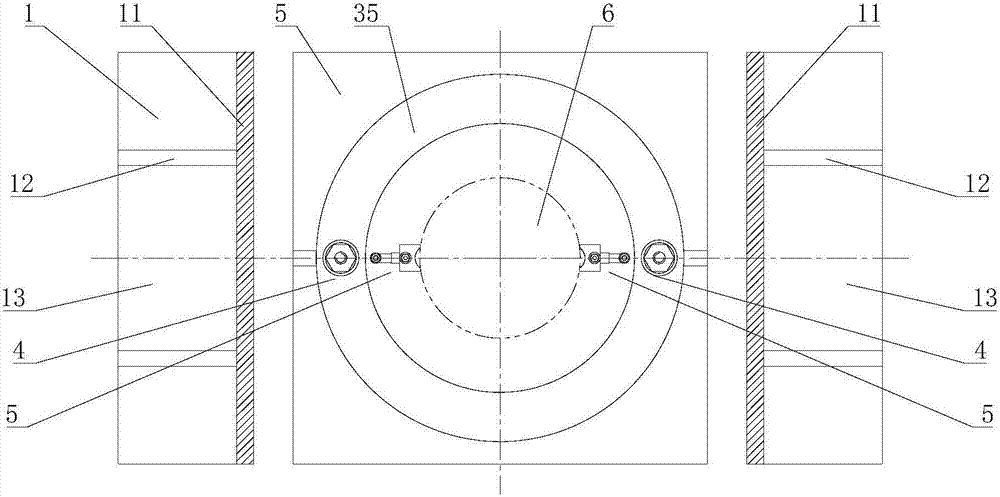

[0030] like Figure 2 to Figure 7 As shown, an egg-shaped pressure shell production device of the present invention includes a support mechanism 1, a die mechanism 2 is connected to the support mechanism 1, a bottom mold mechanism 3 is placed opposite to the axis center directly below the die mechanism 2, and the bottom mold mechanism The mechanism 3 is fixed on the workbench 5 through the locking mechanism 4 .

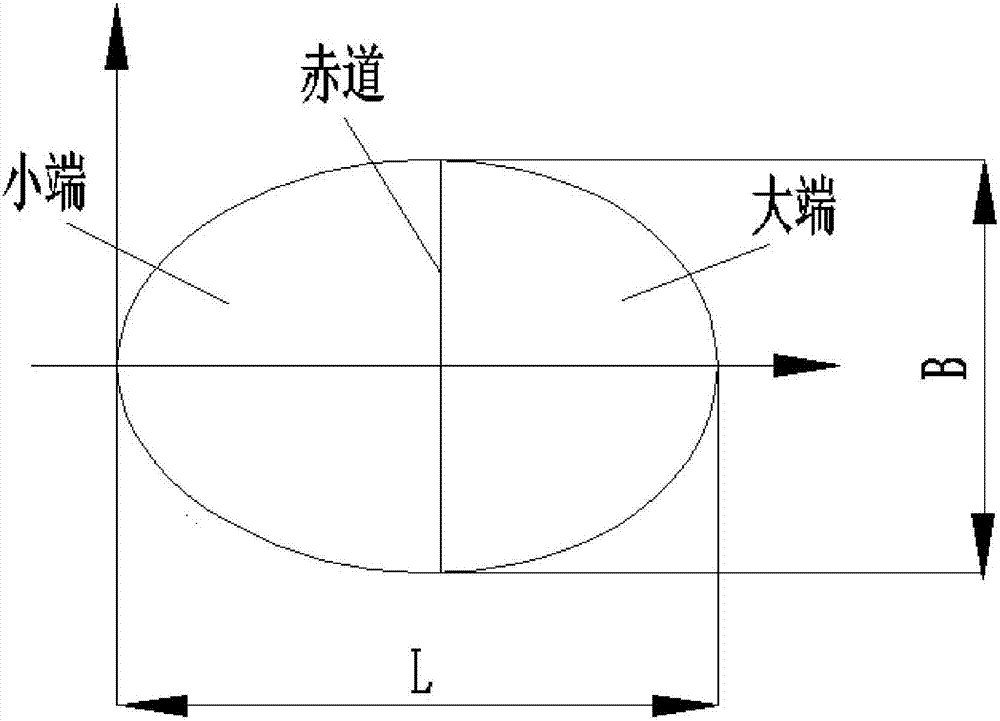

[0031] In the present invention, the mold in the die mechanism 2 and the bottom mold mechanism 3 adopts a general egg-shaped outline, such as figure 1 As shown in the figure, the basic geometric parameters of the egg-shaped shell are included in the long axis L and the short axis B. In order to make the processed mold easy to punch, the equator is used as the dividing line to cut the small end and the large end of the egg-shaped shell respectively, and respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com