Screw type sleeve part side milling multi-station adjustable manual clamp and method

A screw-type, multi-station technology, applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of high labor intensity, low production efficiency, difficult to clamp workpieces, etc., to reduce work intensity and improve production Efficiency, reliable effect of positioning device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

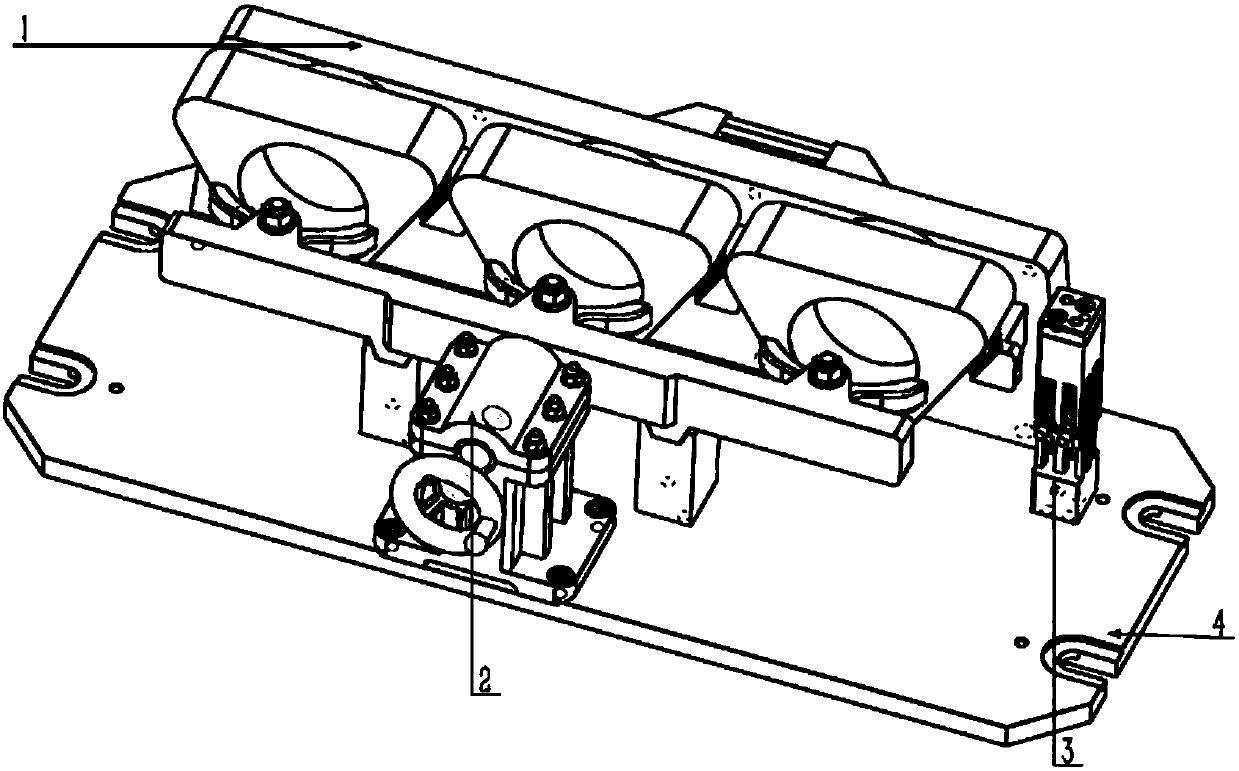

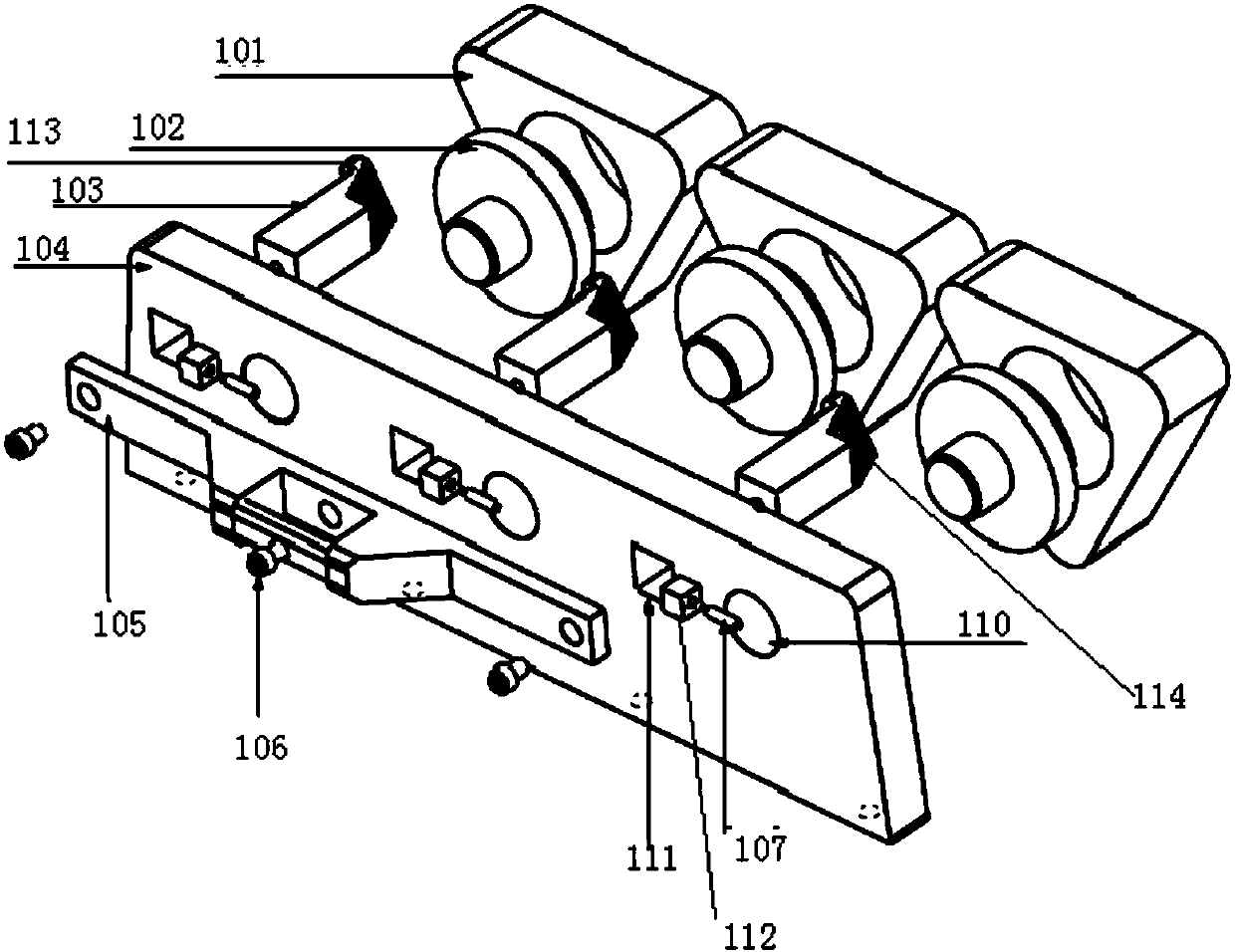

[0064] A multi-position adjustable manual fixture for side milling of screw-type sleeve parts, including a positioning device 1, a clamping device 2, a tool setting device 3 and a clamp body 4, a positioning device 1, a clamping device 2, and a tool setting device 3. It is arranged on the clamp body 4, the positioning device 1 and the clamping device 2 are arranged in parallel, and the tool setting device 3 is arranged on the side of the positioning device 1 and the clamping device 2. The overall design is reasonable, and it can fully fix disc sleeve parts of various sizes and shapes. It uses a combination of large planes and positioning pins plus positioning blocks for positioning. The positioning device is reliable and will not cause secondary damage to the parts. The device can realize multiple milling in one clamping, convenient loading and unloading by manual clamping, and can process multiple workpieces in one clamping at one time, which greatly improves production effici...

Embodiment 2

[0086] The technical scheme of embodiment 2 is different from embodiment 1 except that the workpiece and the positioning block are processed, and other parts are all the same as embodiment 1.

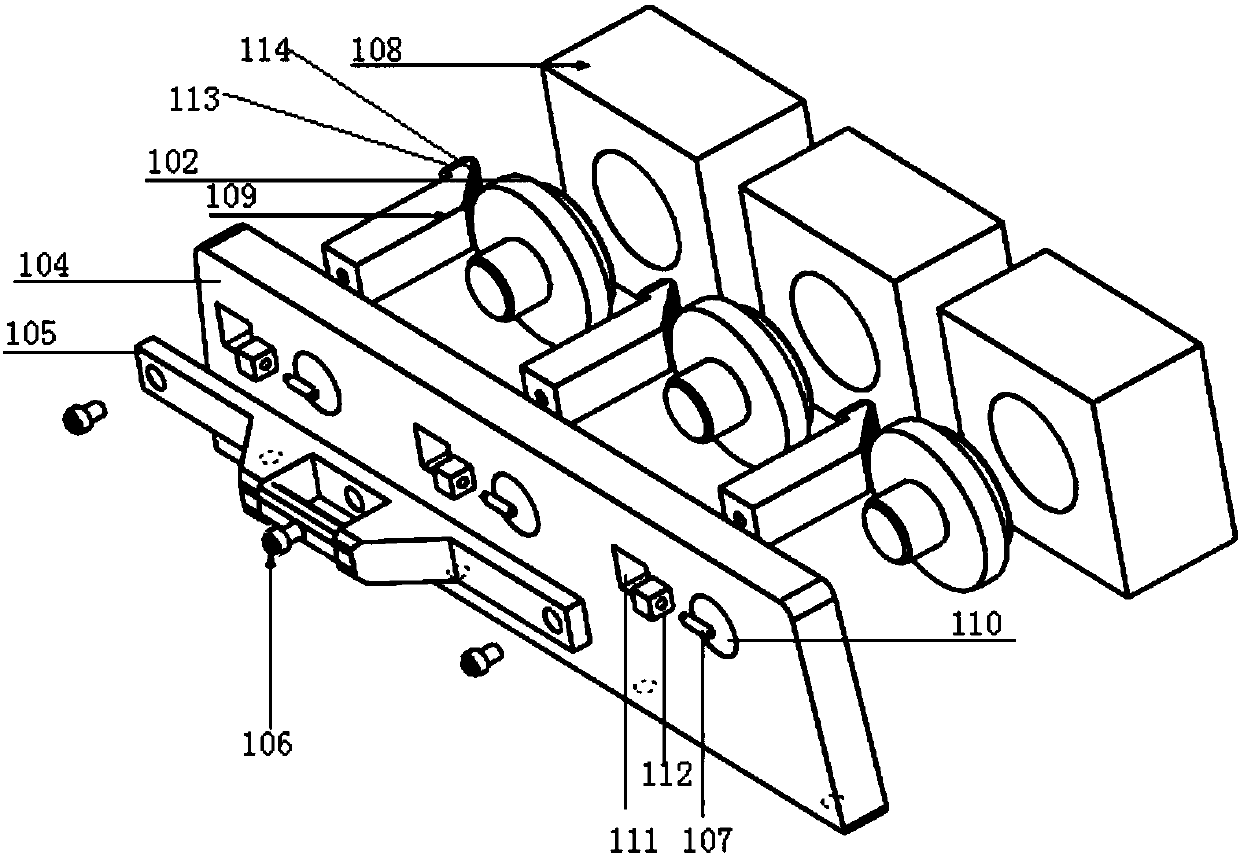

[0087] The front section of the positioning block is provided with a positioning part step surface 114, which can realize the positioning of the workpiece; the front side of the positioning block is provided with a protruding stepped structure 113, which can prevent the positioning block from being pulled out; the positioning block is a four-sided positioning block 109 or an N-sided positioning block, and N is greater than Fourth, it can adapt to different workpieces to be processed.

[0088] When processing four-side workpiece 108 or N side workpiece, three-side positioning block 103 in embodiment 1 is replaced with four-side positioning block 109 or N surface positioning block (N is greater than four), and other processing three-side workpiece 101 is the same.

[0089] image 3 It is...

Embodiment 3

[0093] The technical solution of embodiment 3 is the same as that of embodiment 1 except that the positioning block is a cylinder as a whole and the mounting hole 111 is a round hole, and other parts are the same as embodiment 1.

[0094] For the positioning device 1 , the clamping device 2 , the tool setting device 3 and the clamping body 4 of the third embodiment, refer to the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com