Novel biomedical metal plate machining device

A biomedical and processing device technology, applied in the direction of metal processing equipment, manufacturing tools, workpiece feed movement control, etc., can solve problems such as low efficiency, inability to effectively fix metal plates, lack of emergency stop, etc., to prevent safety accidents, Improve the grinding efficiency and grinding accuracy, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

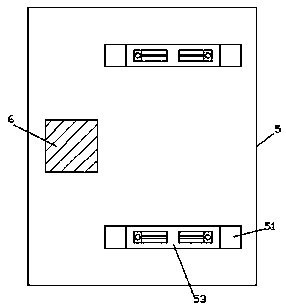

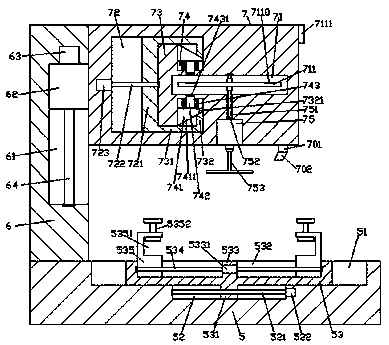

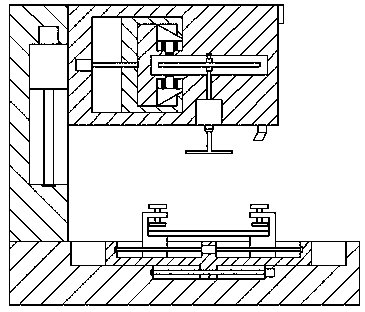

[0023] Such as Figure 1-Figure 5As shown, a novel biomedical metal plate processing device of the present invention includes a base 5 and a grinding device 7 arranged above the top of the base 5, and a vertical column 6 is arranged on the top left side of the base 5, The top surface on the left side of the abutment 5 is provided with first sliding joint grooves 51 in front and back, and each of the first sliding joint grooves 51 is provided with a second sliding joint groove 52 in the middle of the inner bottom surface. The second sliding joint grooves 52 is provided with a first spiral rod 521 extended left and right, the first sliding joint block 53 is slidingly connected in the first sliding groove 51, and the grinding device 7 is provided with a sliding joint cavity 72 inside. The inside of the right side of the sliding connection chamber 72 is provided with a protruding head 73, and the protruding head 73 is provided with a locking chamber 71 extending toward the right s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com