Air cylinder driven type high-pressure quick coupler

A cylinder-driven, high-pressure technology, which is applied to equipment loaded into pressure vessels, installation devices of vessel structures, gas/liquid distribution and storage, etc. Achieve the effect of accurate limit and instruction, realize full automation, and ensure personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

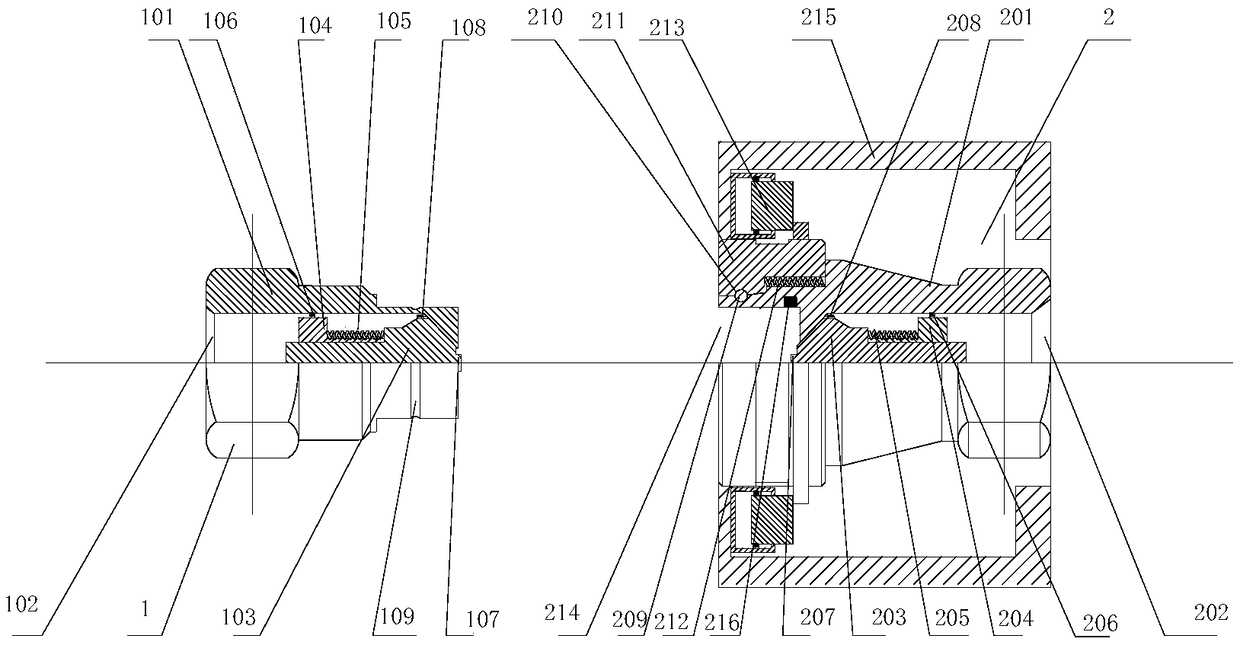

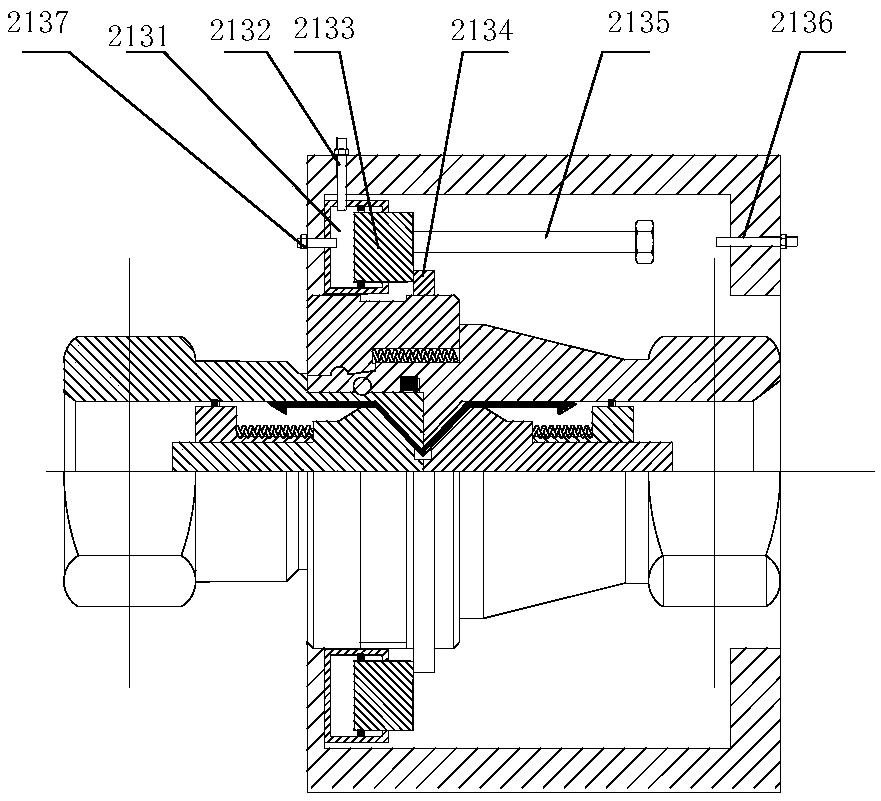

[0019] like Figure 1-2 As shown, this embodiment 1 provides a schematic diagram of a cylinder-driven high-pressure quick-fit joint. The cylinder-driven high-pressure quick-fit joint provided by the present invention includes a male head 1 and a female head 2. The male head 1 includes a male head housing 101, a male head air port 102, a male head sealing body 103, a male head spring limiter 104, a male head Head sealing spring 105, male head limit block mounting pin 106, male head protruding steel column 107, male head sealing ring 108, male head outer groove 109, female head 2 includes female head inner shell 201, female head air port 202, Female head sealing body 203, female head spring limit block 204, female head seal spring 205, female head limit block installation pin 206, female head protruding steel column 207, female head sealing ring 208, female head positioning steel ball 209, steel Ball diffusion groove 210 , female ferrule 211 , clamping positioning spring 212 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com