Production equipment for air conditioner injection molded parts

A technology for production equipment and injection molding equipment, which is applied in the field of production equipment for air-conditioning injection molding parts. It can solve the problems of affecting the service life of injection molding machines, waste of resources, and plastic molding affecting the molten state, so as to improve the yield rate and product quality, and facilitate use. And the effect of installation, easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

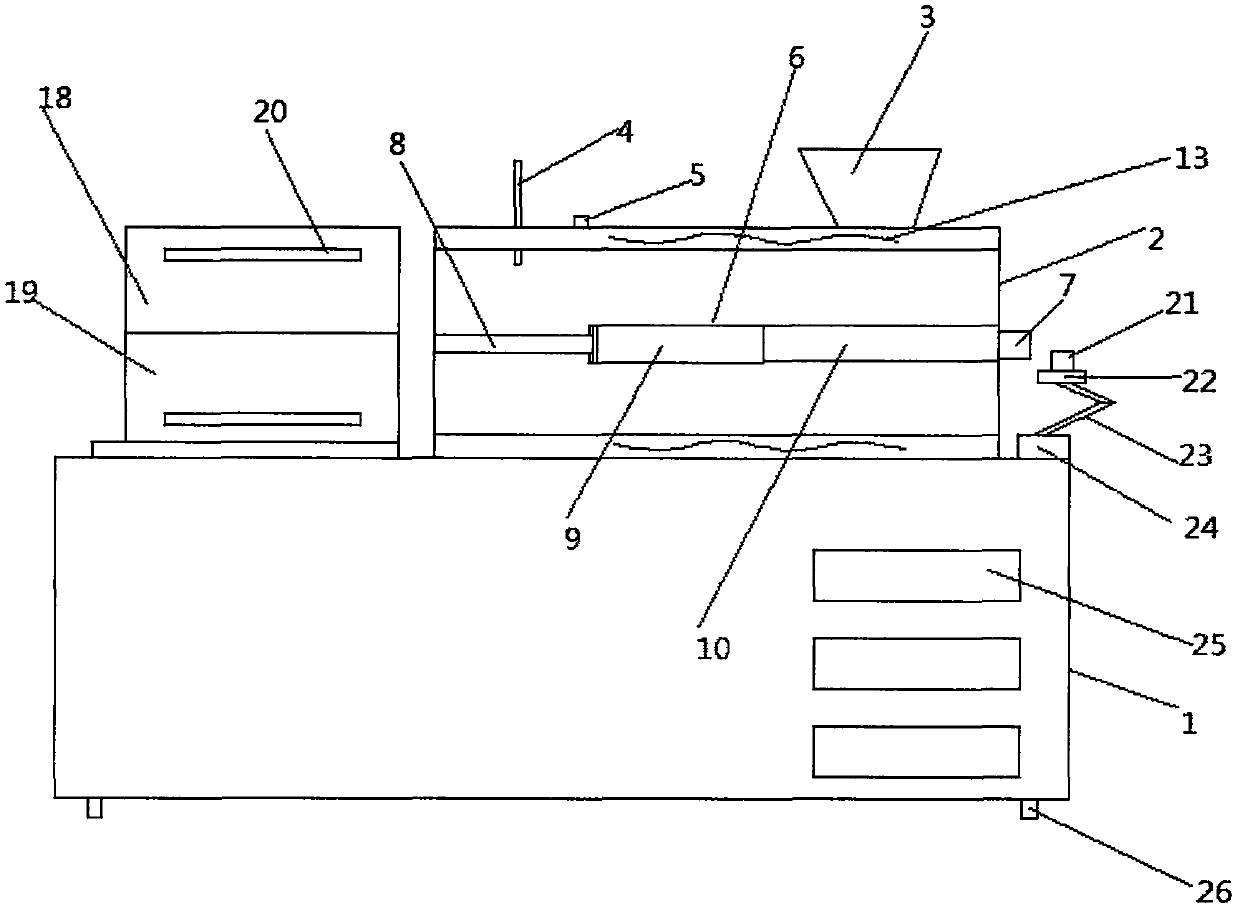

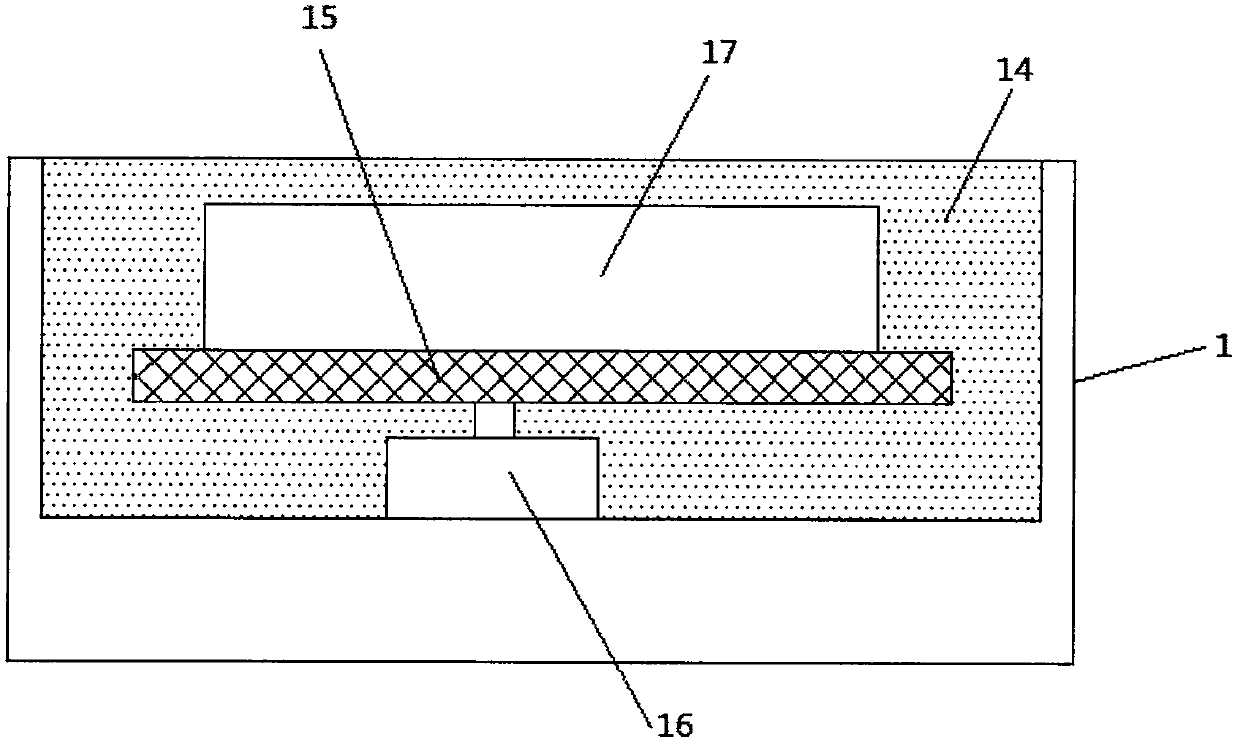

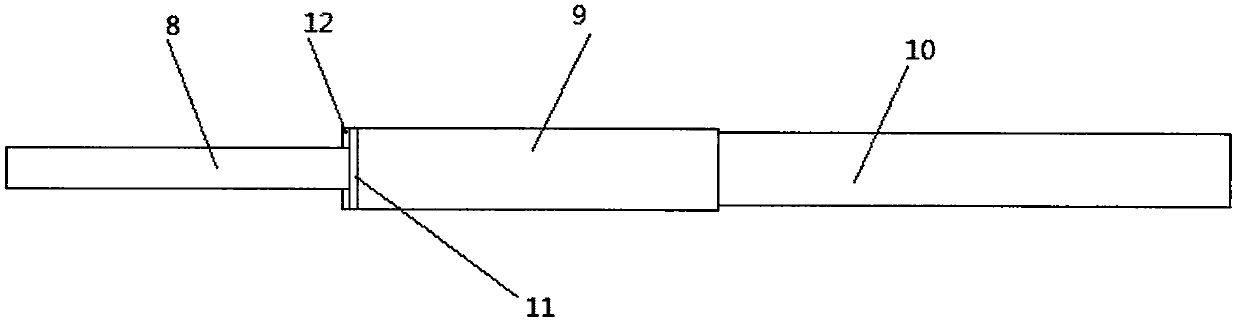

[0017] Such as Figure 1-3 As shown, the production equipment of a kind of air conditioner injection molded parts provided by the present embodiment, it comprises work platform 1, and this work platform 1 is provided with injection molding equipment and the injection mold that is applied to air conditioner injection molded parts, and described injection molding equipment and injection mold are respectively It is detachably connected with the working platform 1, the inside of the working platform 1 is provided with an electrical cabinet, the injection molding equipment and the injection mold are respectively electrically connected with the electrical cabinet, the injection molding equipment includes an injection molding cylinder 2, and the injection molding cylinder 2. The upper surface is provided with a feed hopper 3, a temperature detector 4 and a pressure gauge 5. The injection cylinder 2 is provided with a screw 6, and one end of the screw 6 is provided with a driving devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com