a construction machine

A technology of construction machinery and power machine, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve problems such as large vibration, high noise, and disturbing residents, and achieve the effects of reducing occupied space, improving protection work, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

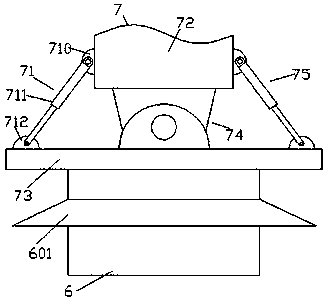

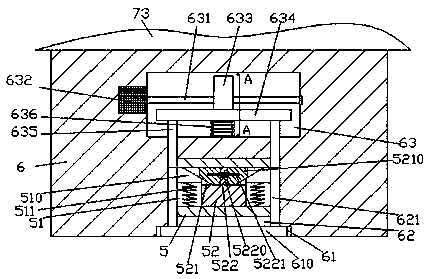

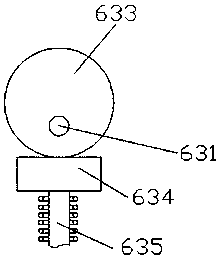

[0016] Such as figure 1 , figure 2 and image 3 As shown, a construction machine of the present invention includes a supporting device 7 and a hammering precursor 6 fixedly installed at the bottom of the supporting device 7, and the bottom surface of the hammering precursor 6 is provided with an accommodation groove 61, and the accommodating A hammering plate 610 is smoothly fitted and connected in the groove 61. The top wall of the containing groove 61 communicates with a first containing cavity 62 extending upwards. The hammering precursor 6 on the upper side of the first containing cavity 62 A second housing chamber 63 is provided inside, and a hammering precursor device is provided in the second housing chamber 63, and a slider 5 that is connected to the hammering precursor device is smoothly fitted and connected in the first housing chamber 62, The left and right sides of the slider 5 are smoothly connected with push rods 621 extending up and down. The top surface is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com