9mw mixed temperature inlet steam control exhaust steam temperature backpressure steam turbine and its temperature adjustment method

A steam turbine and steam inlet technology, which is applied to mechanical equipment, engine components, machines/engines, etc., can solve the problems that the four pumping of the main engine cannot be satisfied, the equipment operation efficiency is low, and the reheated cold end steam cannot meet the 120t/h flow demand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

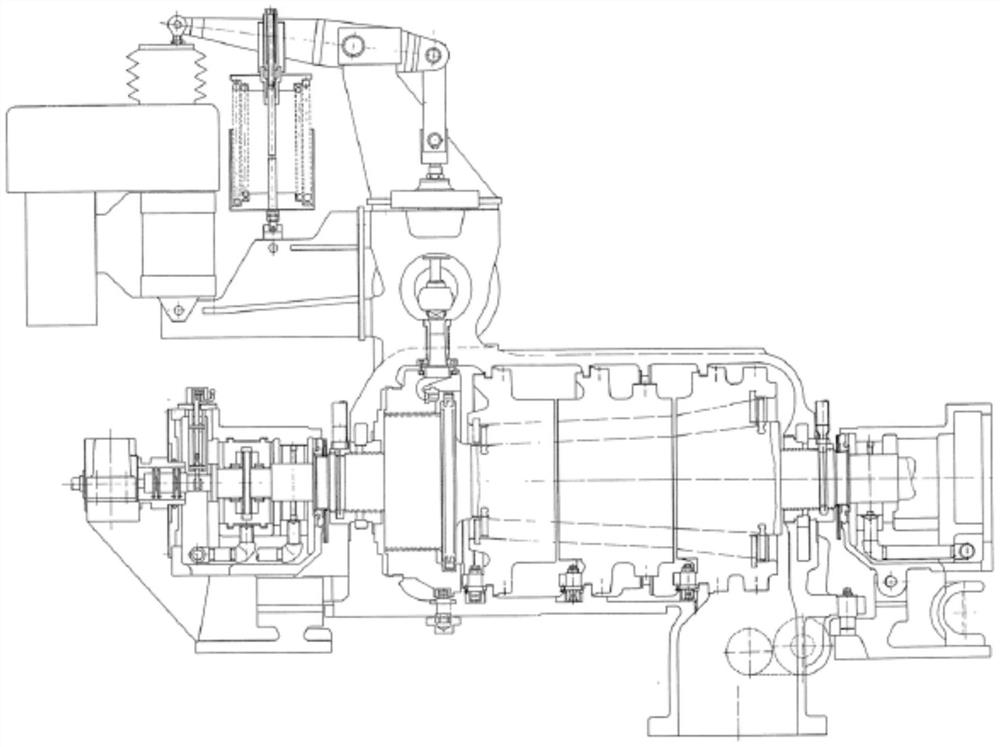

[0016] Embodiment 1: It is suitable for driving a generator by a steam turbine generator set. The steam turbine and the generator are directly connected by a coupling, the speed is 3000rpm, and the power at the 75% THA operating point is 7750KW.

[0017] Basic parameters of steam turbine and THA operating range: Model HNG50 / 40 / 25, normal inlet steam pressure 3.663MPa, normal inlet steam temperature 448.2℃. The steam turbine operates under variable working conditions. The 75% THA working condition point is taken as the design point, and most of the operating conditions are considered to ensure that the output power of the steam turbine can basically be maintained above 7700KW, and at the same time, the relative efficiency of other formal working condition points will not be too high. Low. At the same time, due to the low output power of the 50% THA working condition, it is not recommended to run.

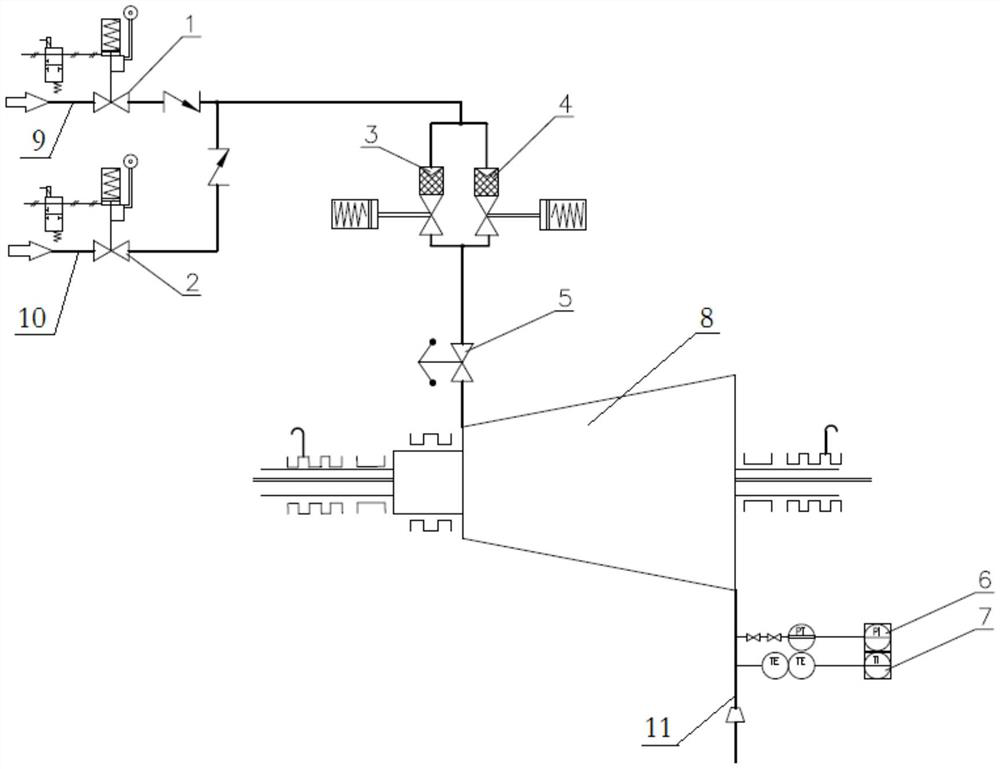

[0018] Such as figure 1 As shown, the 9MW mixed-temperature inlet steam contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com