Lead-acid battery lead parts and its welding method

A lead-acid battery and welding method technology, applied in the direction of lead-acid battery, lead-acid battery construction, electrical components, etc., can solve the problems of affecting the discharge performance of large current, welding cannot be carried out, and the internal resistance of the battery is large, so as to optimize the welding quality , Guarantee the welding quality and simplify the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

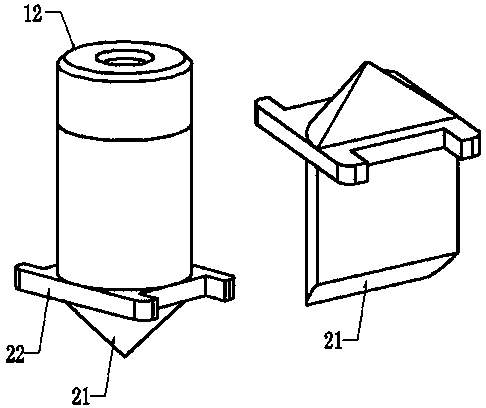

[0026] see figure 2 , is a schematic structural view of the lead parts of the lead-acid storage battery provided by the present invention.

[0027] The lead parts of the lead-acid storage battery include a column head 12 and a butt welding piece 13 . One end of the two is provided with a pointed head 21, and the side is provided with a flying wing 22.

[0028] In particular, concave limiting grooves are further provided on opposite sides of the flying wing 22 to form an "M"-shaped edge.

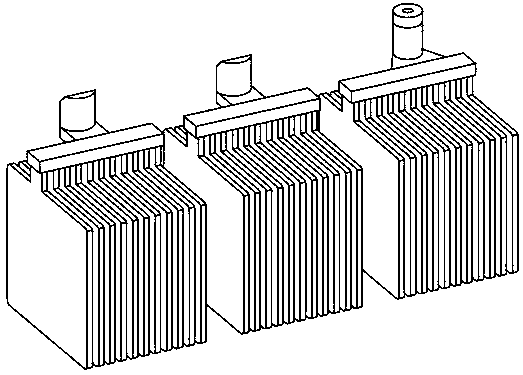

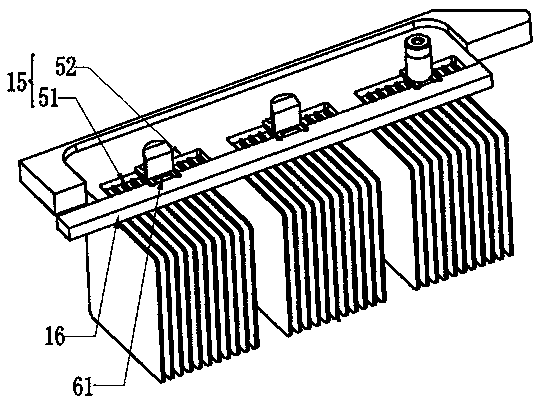

[0029] Please also see image 3 and Figure 4 , image 3 It is an assembly diagram during the implementation of the welding method for the lead parts of the lead-acid battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com