Clamping device for improving steel fixing capacity

A clamping device and capacity technology, applied in the field of clamping devices that improve the ability to fix steel, can solve problems affecting welding accuracy and achieve the effect of improving welding accuracy and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

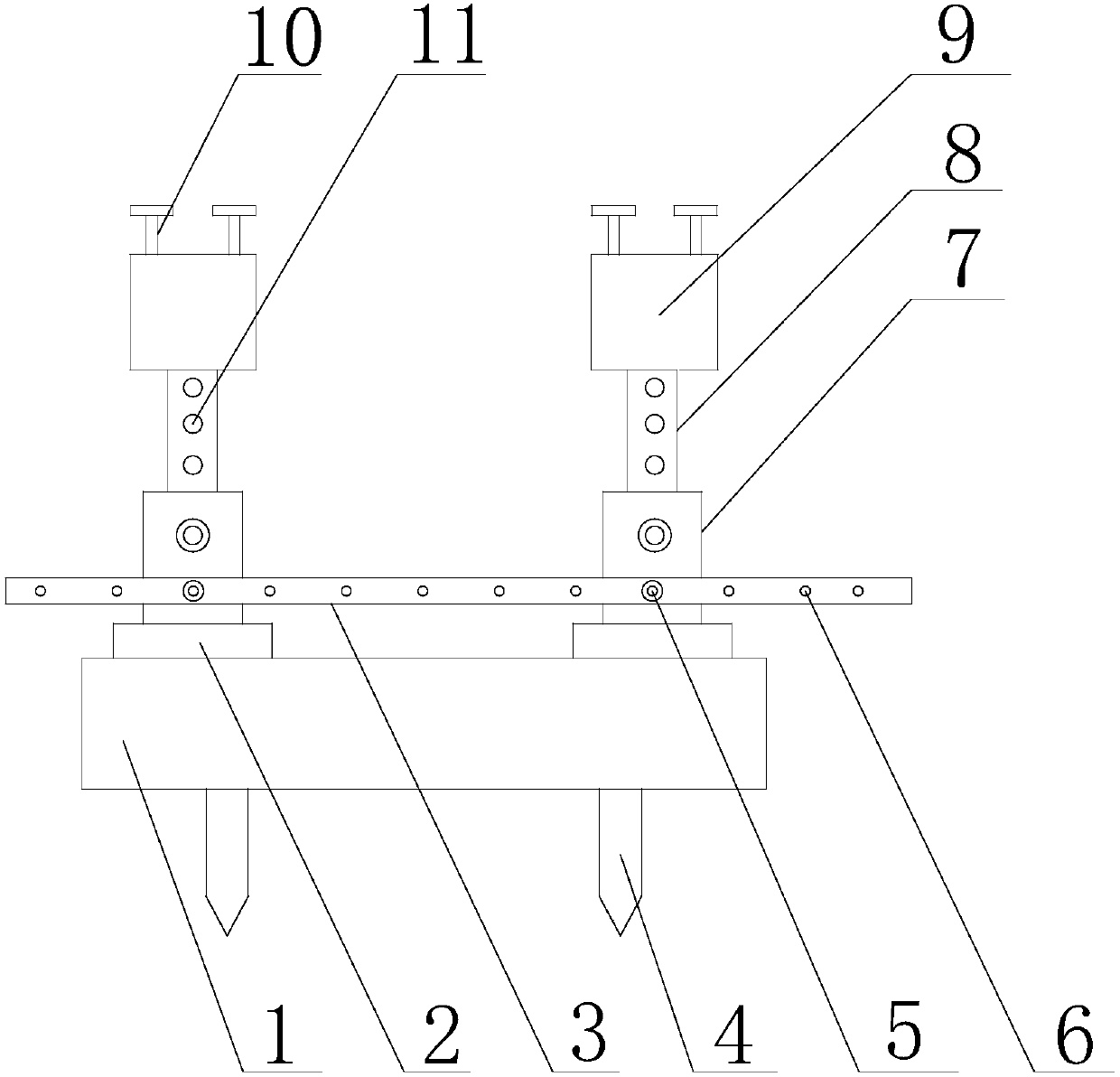

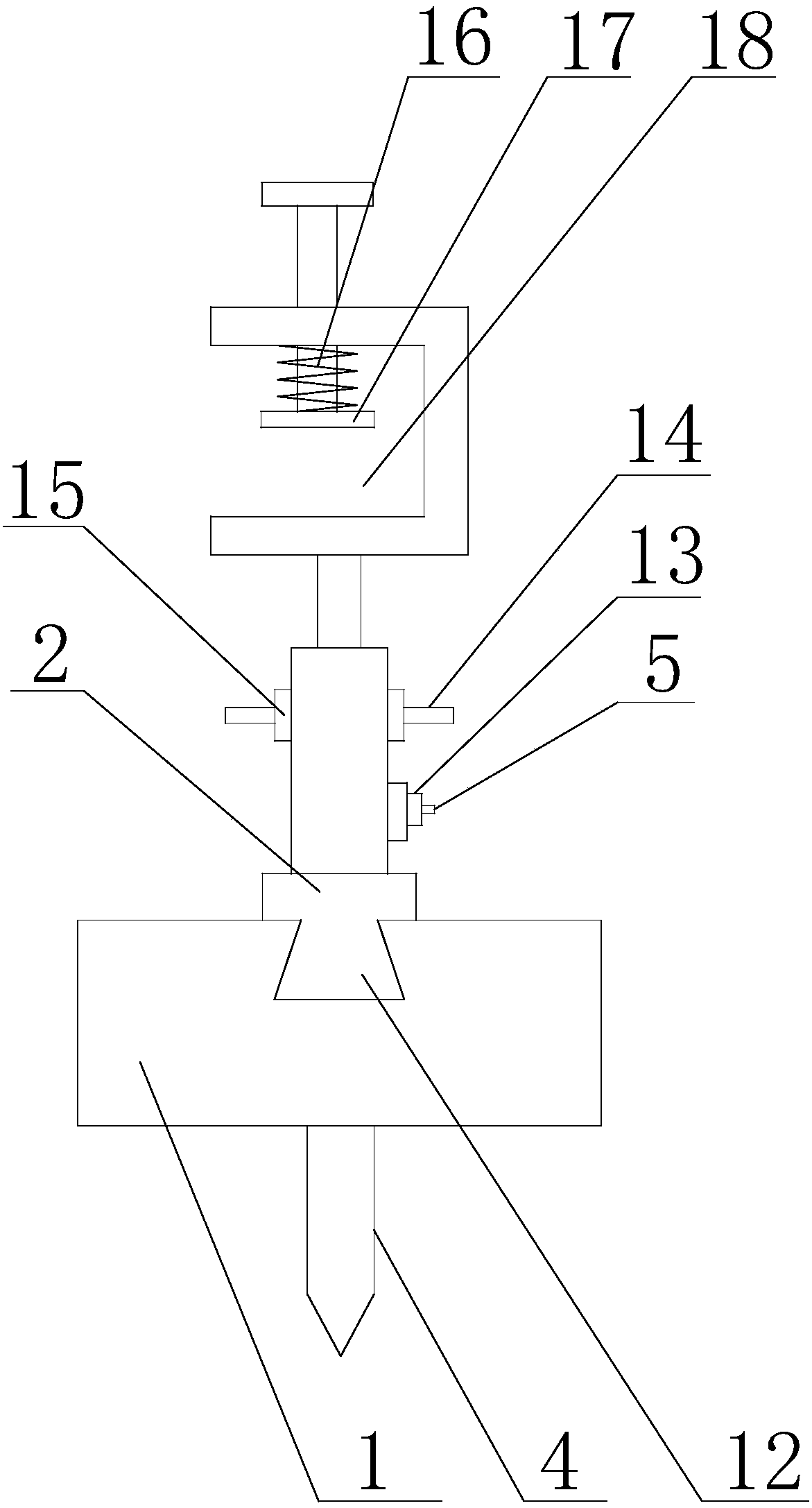

[0025] Such as figure 1 , figure 2 As shown, the clamping device for improving the fixing ability of steel in the present invention includes a base 1, the base 1 is a rectangular structure, the bottom of the base 1 is provided with two embedded frames 4, and the bottom of the embedded part 4 is conical. It is convenient to insert into the soil. The function of the pre-embedded frame 4 is to fix the base 1 on the construction site and prevent the base 1 from shifting. The slider 12, the slider 12 can move in the groove, the top of the slider 12 is provided with a movable block 2, the movable block 2 can move with the slider 12, and the top of the movable block 2 is provided with a support Tube 7, the inside of the support tube 7 is a cavity structure, and the cavity communicates with the top of the support tube 7, the cavity of the support tube 7 is provided with a support rod 8, the support rod 8 is vertically connected with the support tube 7, and The support rod 8 can mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com