Separation plate iron ring extruding machine special for gearbox

A gearbox and extruder technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as inability to install, damage to partitions, extrusion deformation, etc., to improve service life and improve production quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

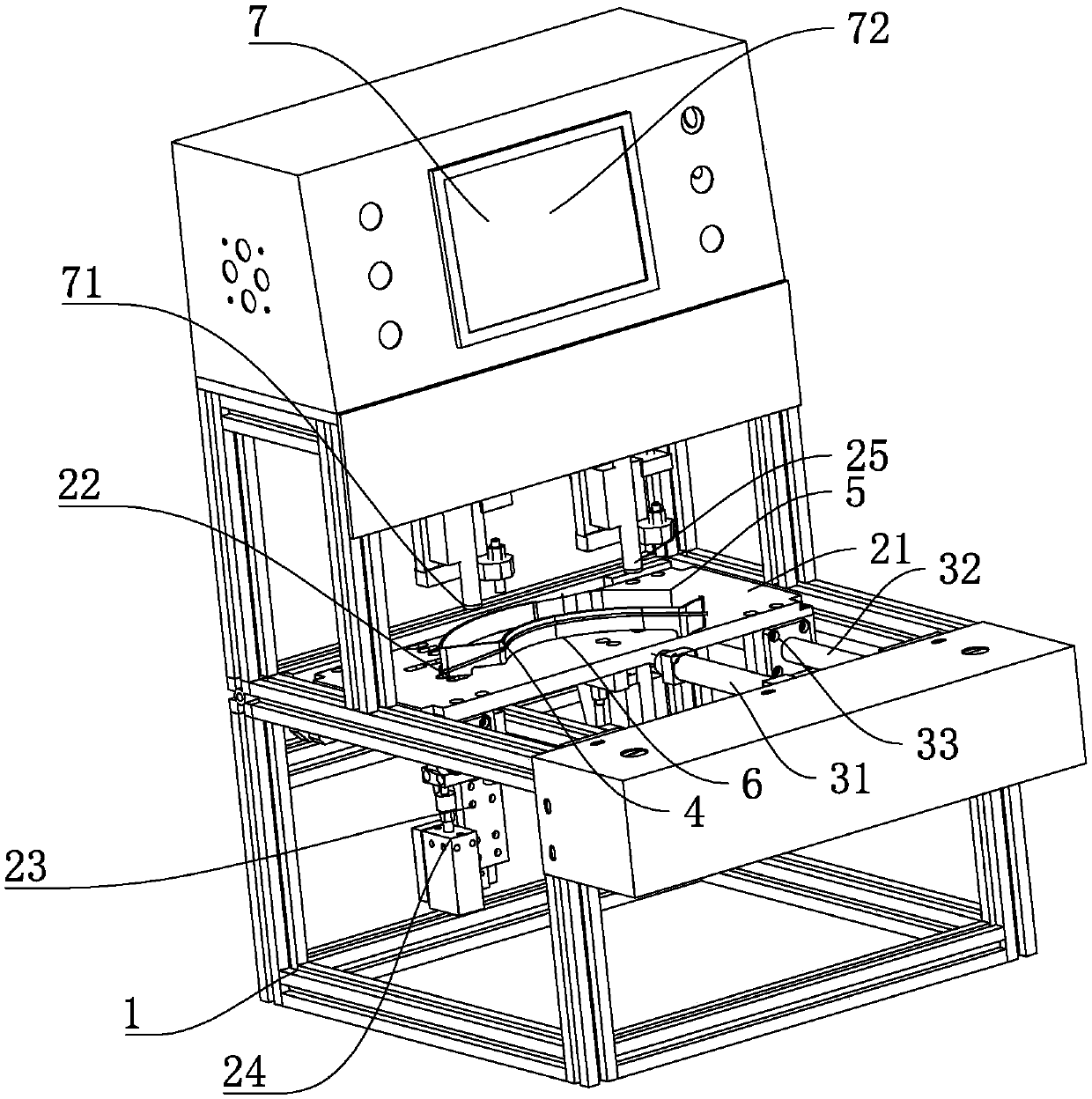

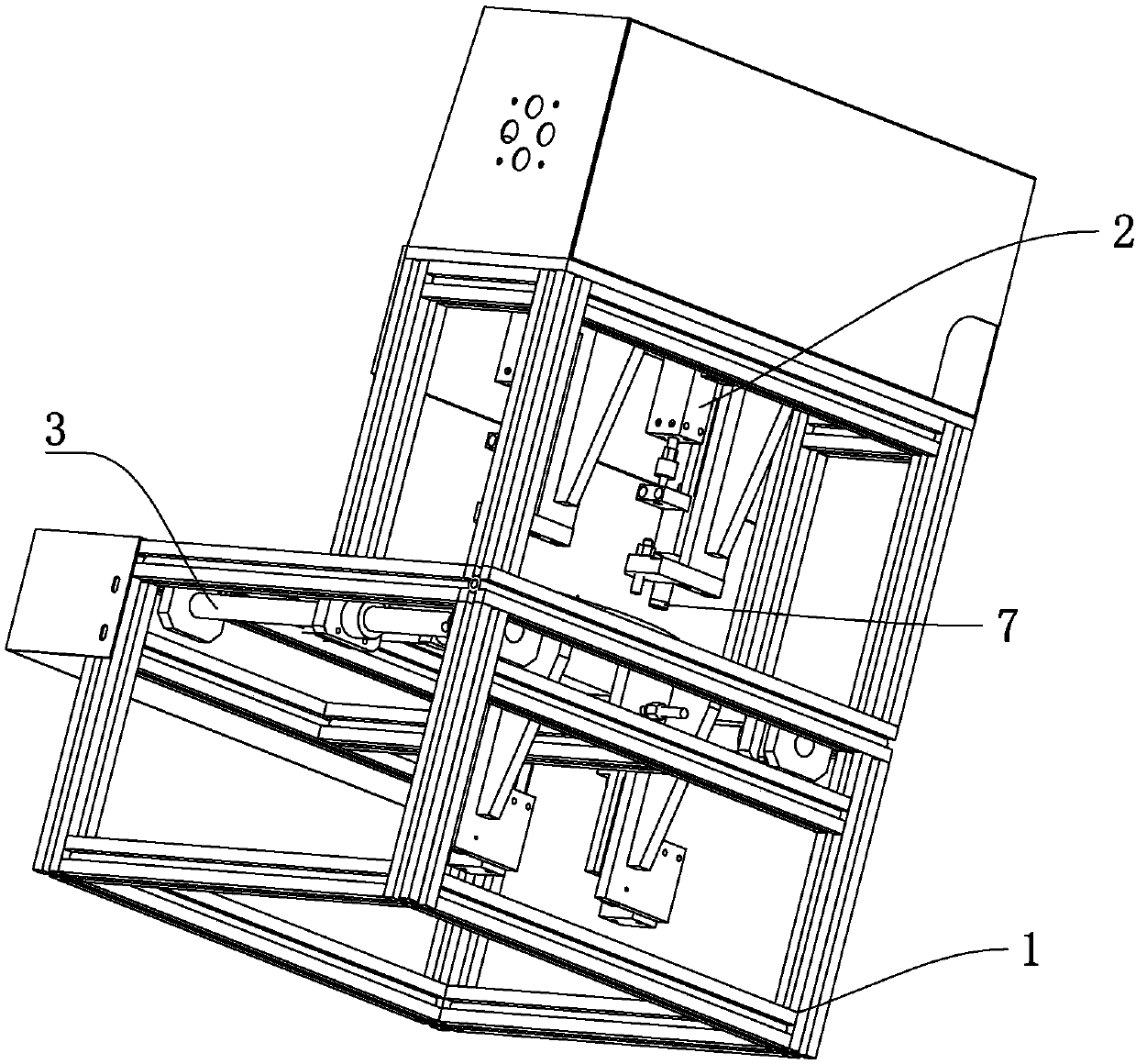

[0021] Embodiment 1: A special clapboard iron ring extrusion machine for gearbox, such as figure 1 and figure 2 As shown, a frame 1 is included, and a crimping device 2 is provided on the frame 1. The crimping device 2 includes a platform 21 positioned horizontally on the frame 1. Parts are usually processed on the platform 21, and a crimping device 2 is provided on the platform 21. There are several different station holes 22 for processing parts of different sizes. The frame 1 at the upper and lower ends of the platform 21 is also provided with a fixed mount 23. The fixed mount 23 is respectively provided with a vertically downward and vertical Straight upward cylinder 24, the outlet of cylinder 24 is provided with the extruding rod 25 that is positioned on the same straight line with station hole 22.

[0022] Extrusion bar 25 is also provided with detecting device 7, and detecting device 7 comprises the current sensor 71 that is positioned at extruding bar 25 tops and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com