Space material passive experiment sample installation structure, sample module and test box

A technology for installing structures and samples, which is applied in the field of aerospace material exposure experiments, can solve problems such as material aging and embrittlement, structural deformation, radiation heat transfer effects, etc., and achieve reliable mechanical properties, compact structure, and low weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

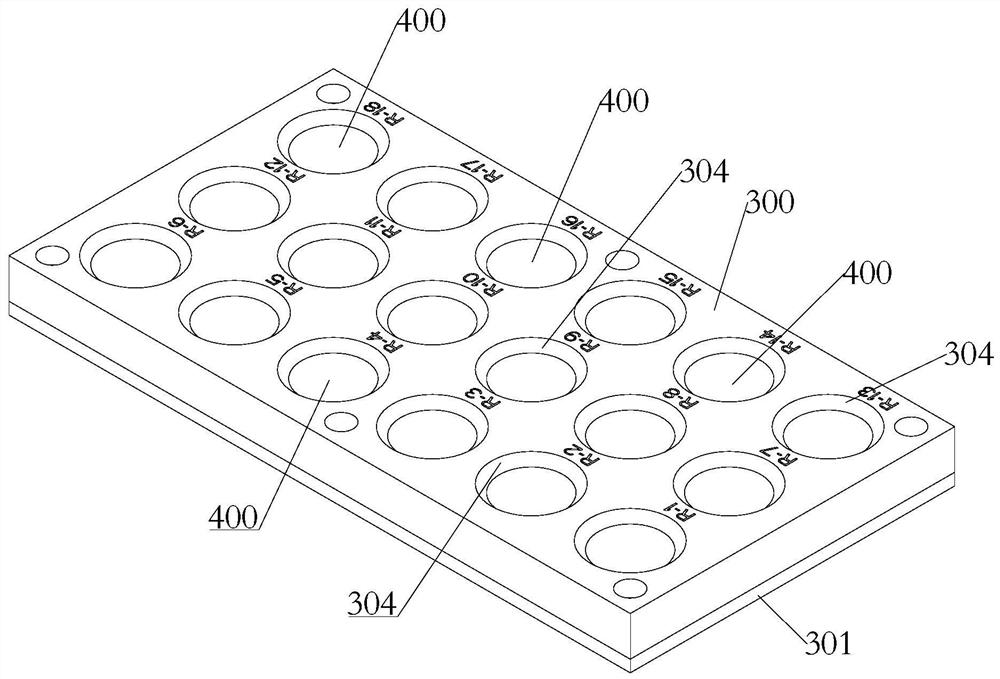

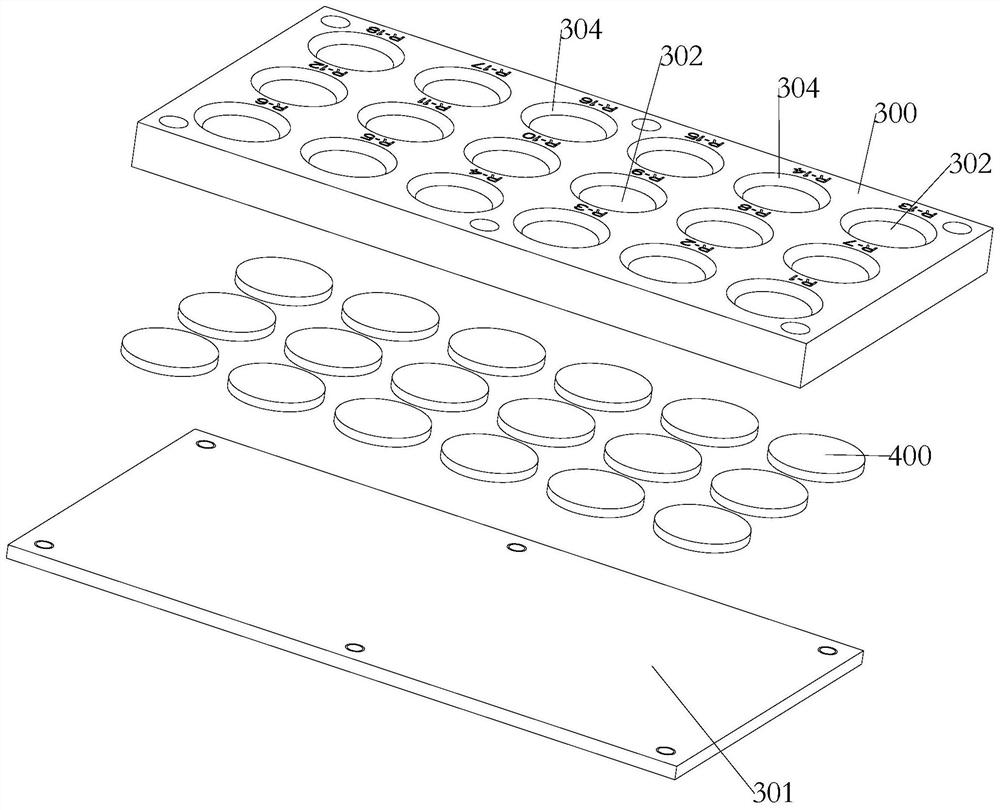

[0070] like Figure 1-Figure 3 As shown, a space material passive experimental sample installation structure in this embodiment includes an upper cover plate 300 and a lower cover plate 301, the upper cover plate 300 is provided with a number of exposure holes 302, and the upper end of the exposure holes 302 is inner ring There is a ring of pressing edge 303 on the side, the upper end of the pressing edge 303 is provided with a circle of chamfers 304 near the exposure hole 302, and the specific design chamfer is 45°; the lower cover 301 can be detachably installed on the upper cover At the lower end of the plate 300 , an installation space for installing materials is formed between the lower cover plate 301 and the pressing edge 303 .

[0071] like Figure 1-Figure 3 As shown, a material passive experiment sample module in this embodiment includes a sample material and the above-mentioned material passive experiment sample installation structure, and the sample material is ad...

Embodiment 2

[0073] like Figure 4-Figure 7 As shown, a space material passive experimental sample installation structure in this embodiment includes an upper cover plate 300 and a lower cover plate 301, the upper cover plate 300 is provided with a number of exposure holes 302, and the upper end of the exposure holes 302 is inner ring There is a ring of pressing edge 303 on the side, the upper end of the pressing edge 303 is provided with a circle of chamfers 304 near the exposure hole 302, and the specific design chamfer is 45°; the lower cover 301 can be detachably installed on the upper cover At the lower end of the plate 300 , an installation space for installing materials is formed between the lower cover plate 301 and the pressing edge 303 .

[0074] like Figure 4-Figure 7 As shown, the sample module of this embodiment further includes an O-ring 305, a spacer 306 and a support plate 307, the O-ring 305 is located below the blank holder 303, and the spacer 306 is located at the O-ri...

Embodiment 3

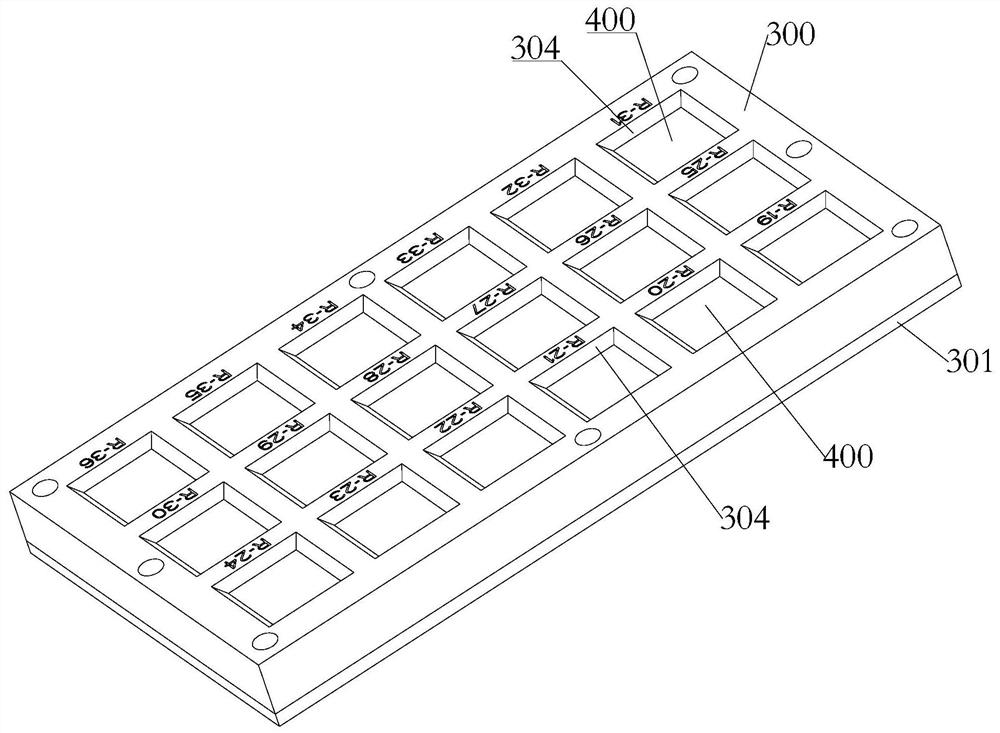

[0079] like Figure 8-Figure 10 As shown, a space material passive experimental sample installation structure in this embodiment includes an upper cover plate 300 and a lower cover plate 301, the upper cover plate 300 is provided with a number of exposure holes 302, and the upper end of the exposure holes 302 is inner ring There is a ring of pressing edge 303 on the side, the upper end of the pressing edge 303 is provided with a circle of chamfers 304 near the exposure hole 302, and the specific design chamfer is 45°; the lower cover 301 can be detachably installed on the upper cover At the lower end of the plate 300 , an installation space for installing materials is formed between the lower cover plate 301 and the pressing edge 303 .

[0080] like Figure 8-Figure 10 As shown, the sample module of this embodiment further includes a spacer plate 308 and an elastic support plate 309, the elastic support plate 309 is located above the lower cover plate 301, and the spacer plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com