Cam rotor hydraulic motor for distributing oil in abdominal cavity

A cam rotor, hydraulic motor technology, applied in the direction of rotary piston engine, rotary or oscillating piston engine, machine/engine, etc., can solve the problem of processing difficulty and processing cost, increasing equipment volume and energy consumption, and difficult sealing problems. Solve and other problems to achieve the effect of easy processing, reduced volume, and effective sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

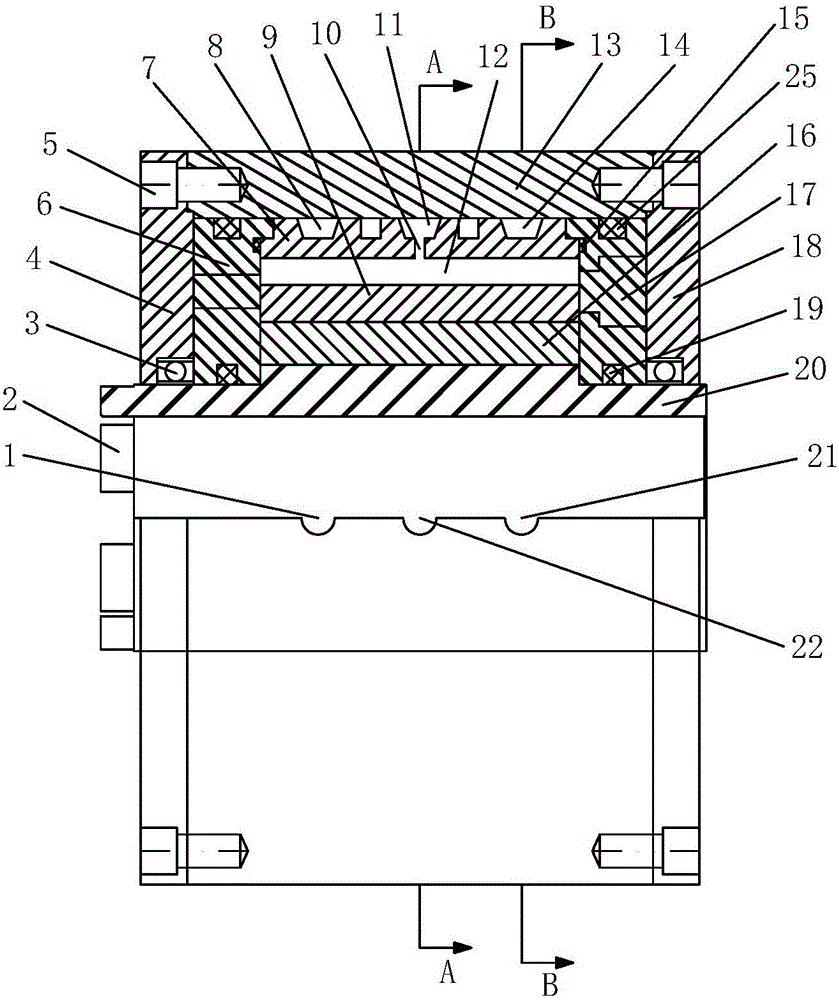

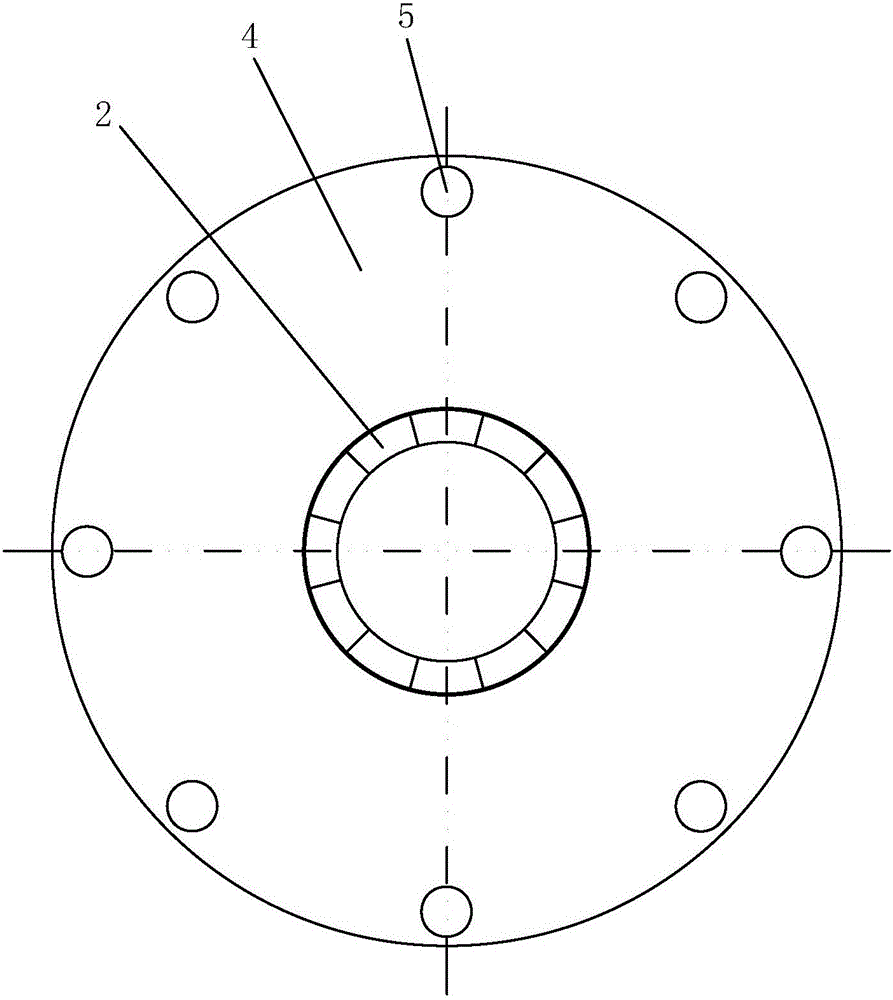

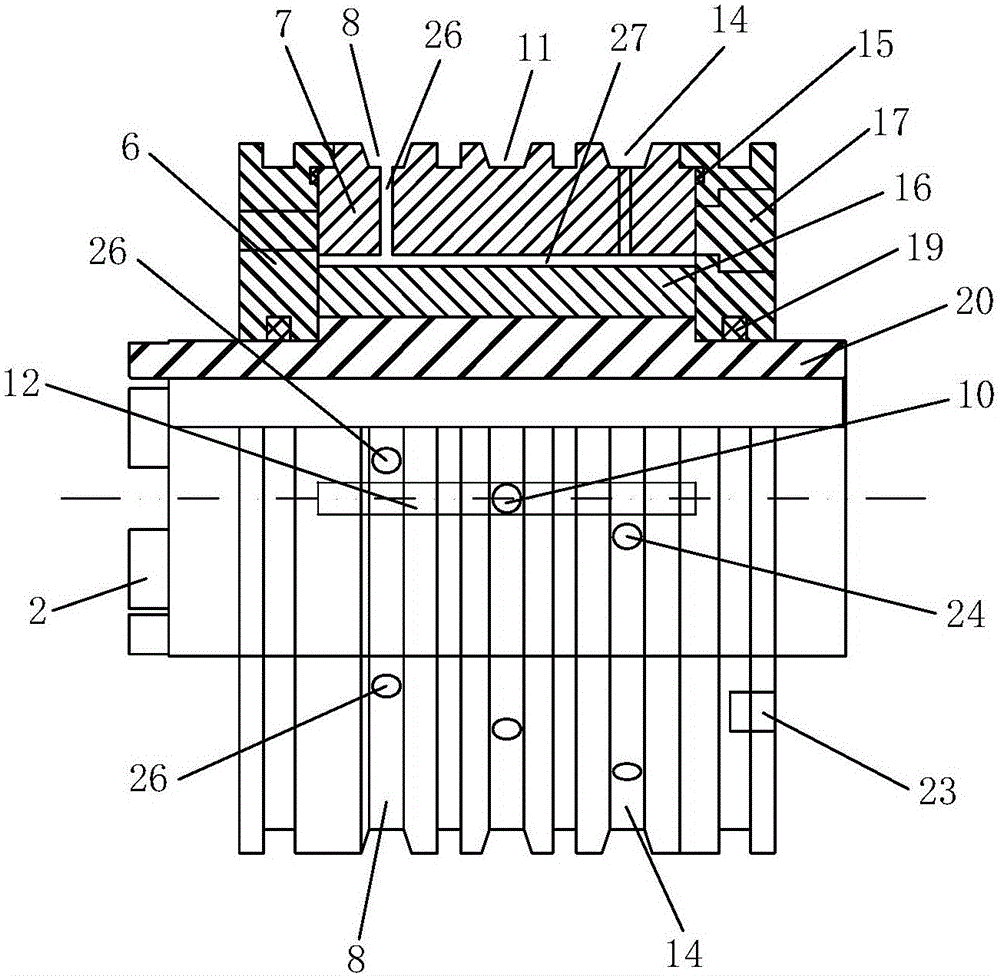

[0047] Such as Figure 1 to Figure 5 As shown, the present invention includes a shaft sleeve 20 and a concave cam rotor 16 fixedly installed on the shaft sleeve 20, a left stopper 6 and a right stopper 17 are rotatably installed on the shaft sleeve 20, and the left stopper 6 and the right stopper The stoppers 17 are located at the left and right ends of the concave cam rotor 16 respectively, a stator 7 is fixed between the left stopper 6 and the right stopper 17, and the stator 7 is sleeved outside the concave cam rotor 16, and the outside of the stator 7 A housing 13 is fixed, and the housing 13 is provided with a housing oil return interface 1, a blade oil inlet interface 22 and a housing oil inlet interface 21. The stator 7 is a hollow cylindrical structure, and an annular return port is provided on the outer wall of the stator 7. Oil groove 8, annular vane oil groove 11 and annular oil inlet groove 14, the inner wall of the stator 7 is provided with a plurality of vane oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com