Multi-degree-of-freedom palm based on rod type ultrasonic motor and operation method thereof

A technology of ultrasonic motors and degrees of freedom, applied in the field of machinery, can solve problems such as joints not being completely independent, coupling phenomena, large redundant structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

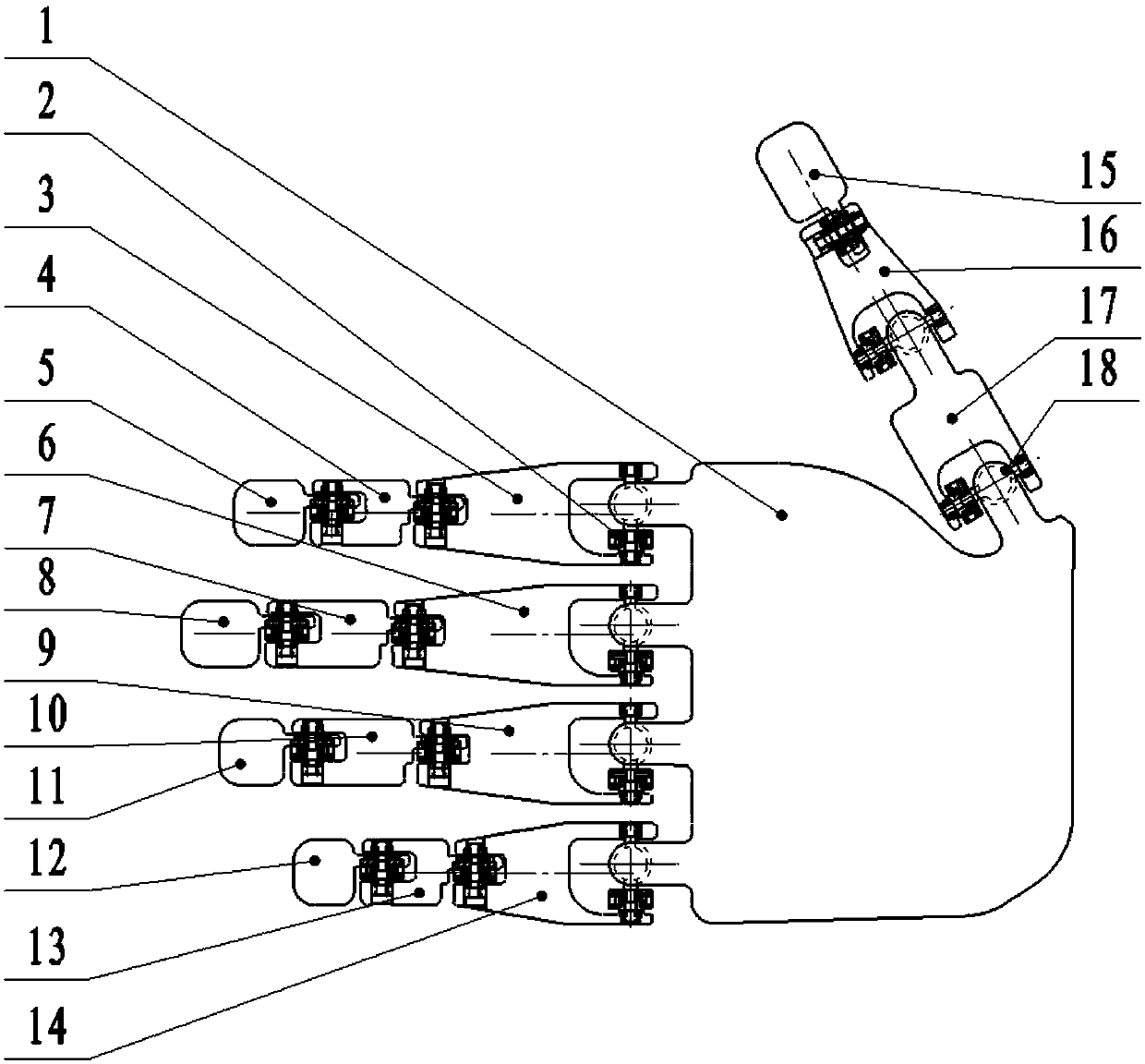

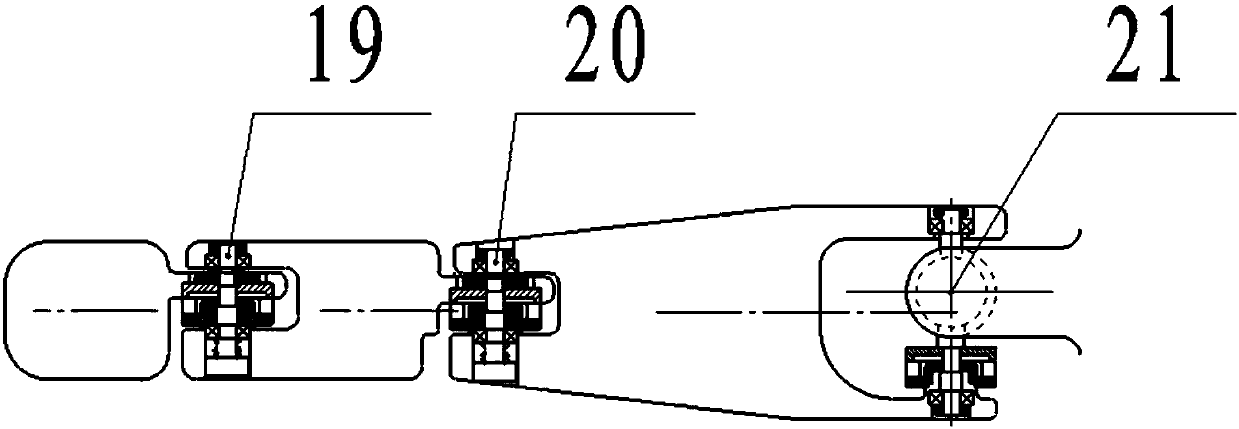

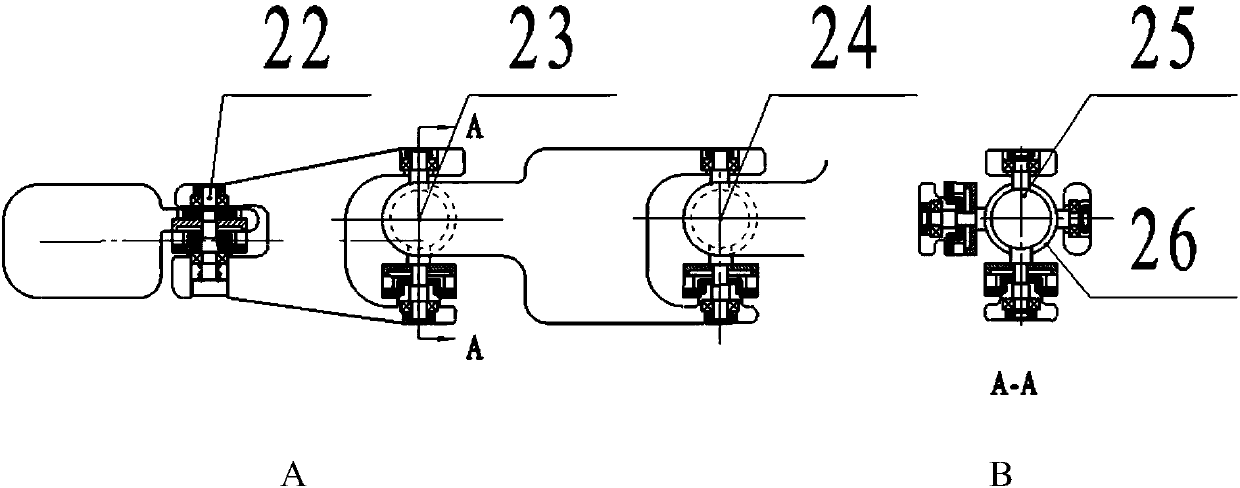

[0021] refer to figure 1 , a multi-degree-of-freedom palm based on a rod-type ultrasonic motor, including a palm 1, a 10mm ultrasonic motor 2, a proximal end of the index finger 3, a middle finger end of the index finger 4, a distal end of the index finger 5, a proximal end of the middle finger 6, and a middle finger end of the middle finger 7 , Middle finger distal end 8, ring finger proximal end 9, ring finger middle finger end 10, ring finger distal end 11, little finger distal end 12, little finger middle finger end 13, little finger proximal end 14, thumb distal finger end 15, thumb middle finger end 16. The proximal end of the thumb 17 and the spherical hinge 18; the first joints of the palm 1 thumb, index finger, middle finger, ring finger and little finger are all connected to the spherical hinge 18, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com