Injection molding machine safety door adopting linear ball bearing

A ball bearing and injection molding machine technology, applied in the field of injection molding machine safety doors, can solve problems such as short service life, safety accidents, and poor safety performance, and achieve the effects of long service life, improved safety, and low frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

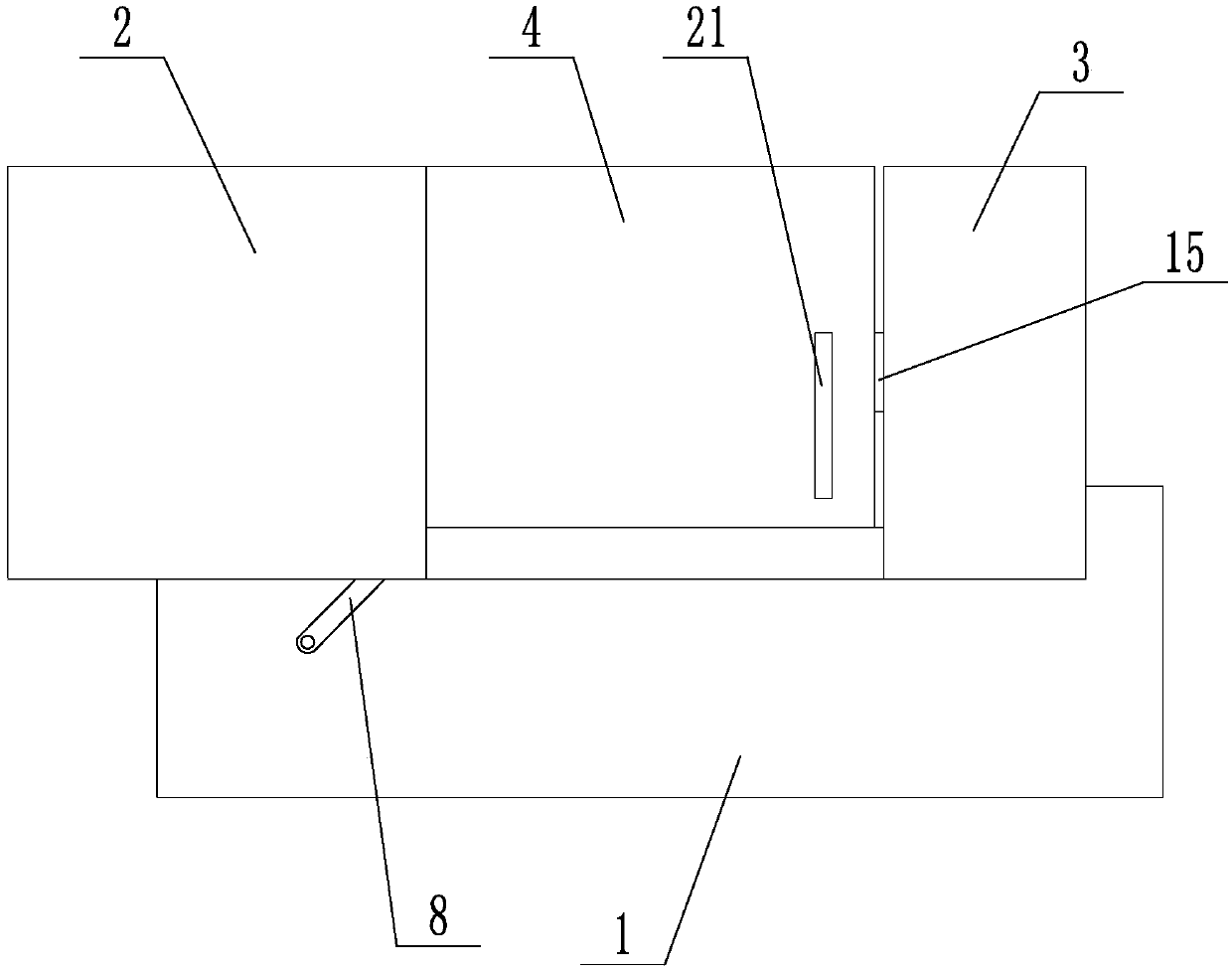

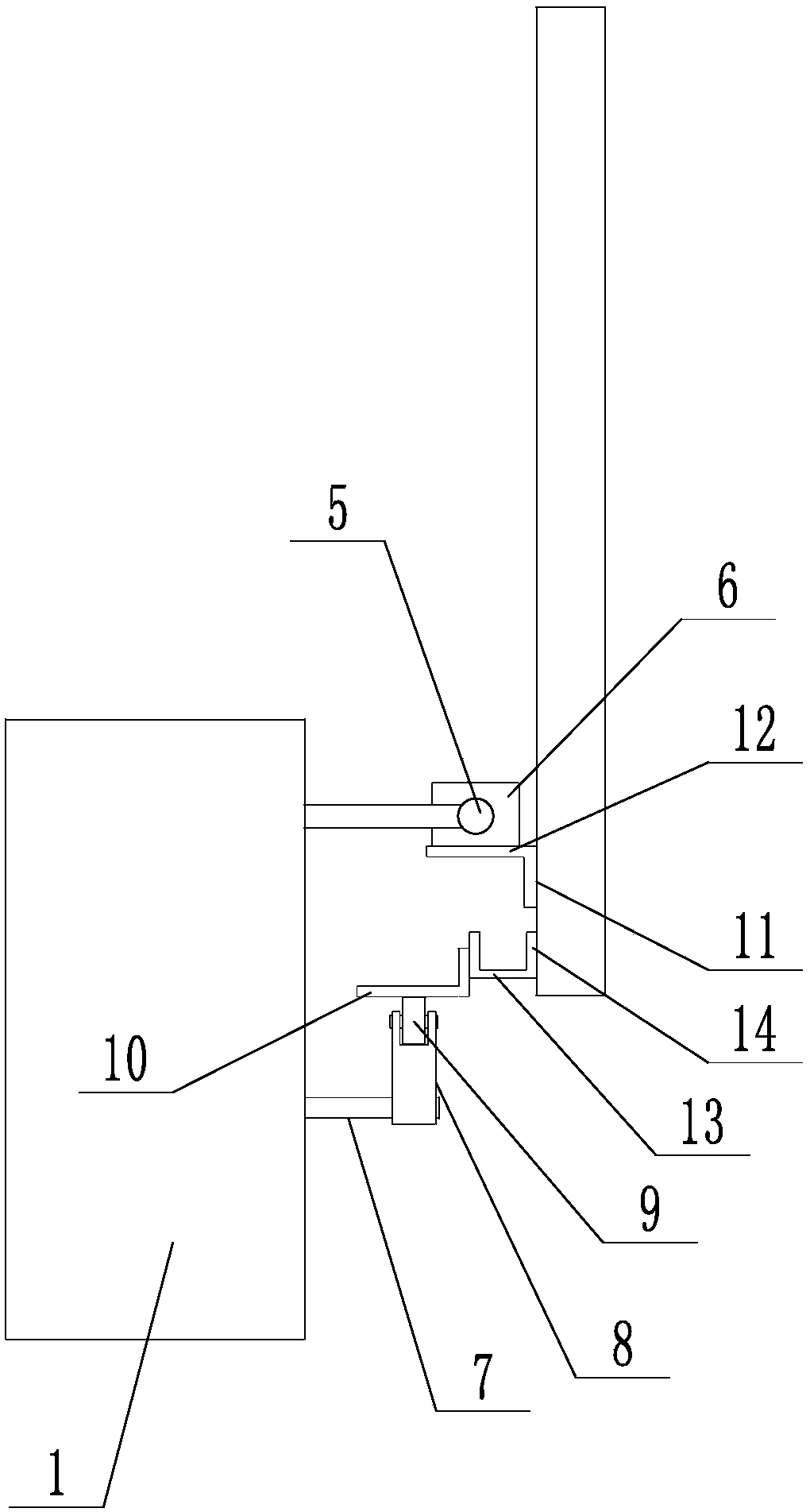

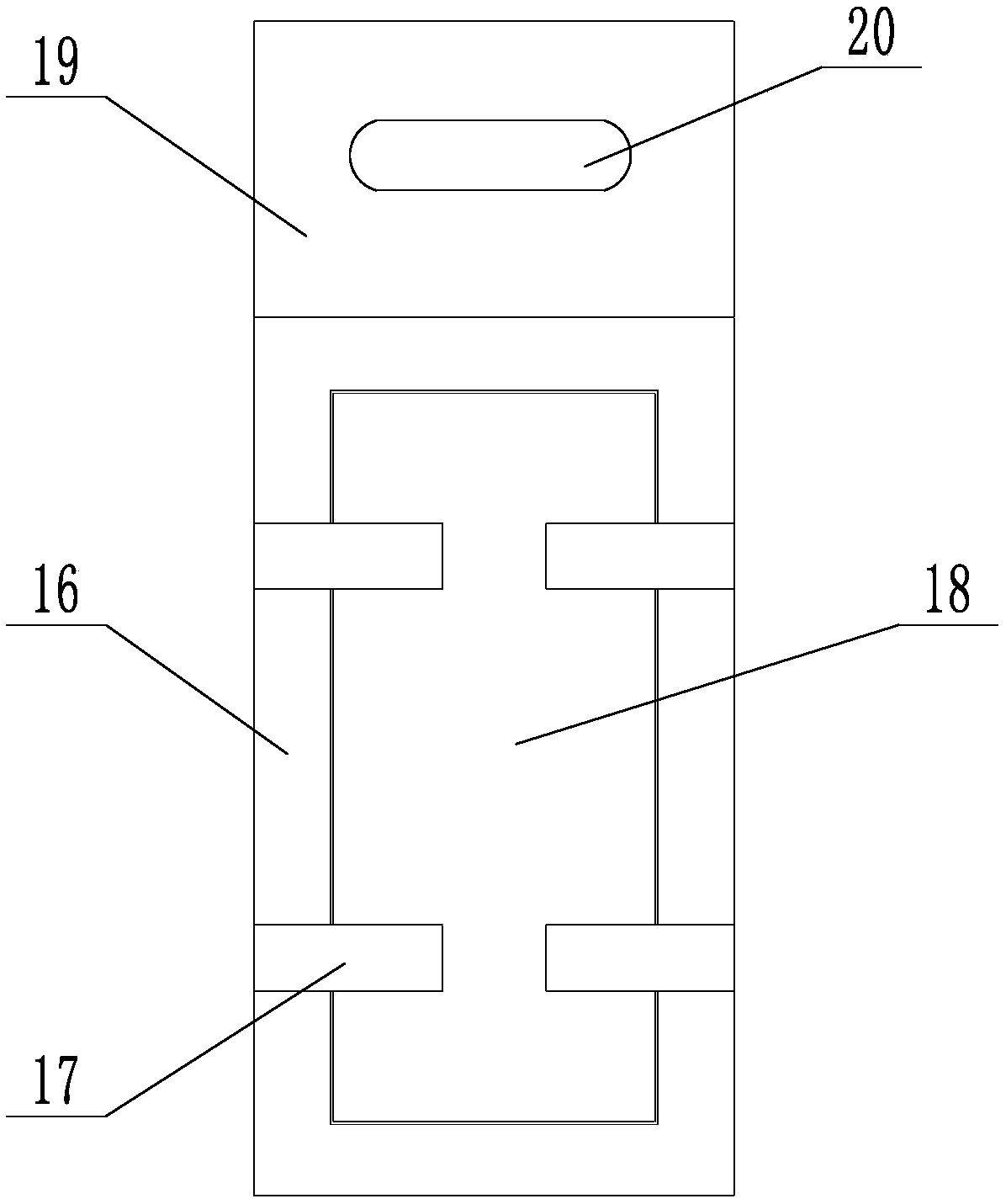

[0017] Such as figure 1 with figure 2 As shown, a safety door for an injection molding machine using a linear ball bearing includes a base 1, the edge of the base 1 is fixedly provided with a left side plate 2 and a right side plate 3, and the left side plate 2 and the right side plate 3 can slide Adjusting door panel 4 is provided in the injection molding machine, in order to make the appearance of the injection molding machine more beautiful, and to protect the connection structure of the adjusting door panel 4, the bottom of the adjusting door panel 4 can be provided with a baffle plate, and the two sides of the baffle plate are connected with the left side panel 2 and the right side panel respectively. The side panels 3 are connected, and the adjusting door panel 4 can move toward the left side panel 2 and the right side panel 3 respectively. When the adjusting door panel 4 moves toward the left side panel 2, the adjusting door panel 4 is gradually opened. During movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com