Anti-looseness conjoined cap for bolts

A bolt and anti-loosening technology, applied in the directions of bolts, screws, nuts, etc., can solve the problems of low driving safety factor, high labor intensity, and large workload, and achieve the effect of wide applicability, simple structure, and preventing bolts from falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

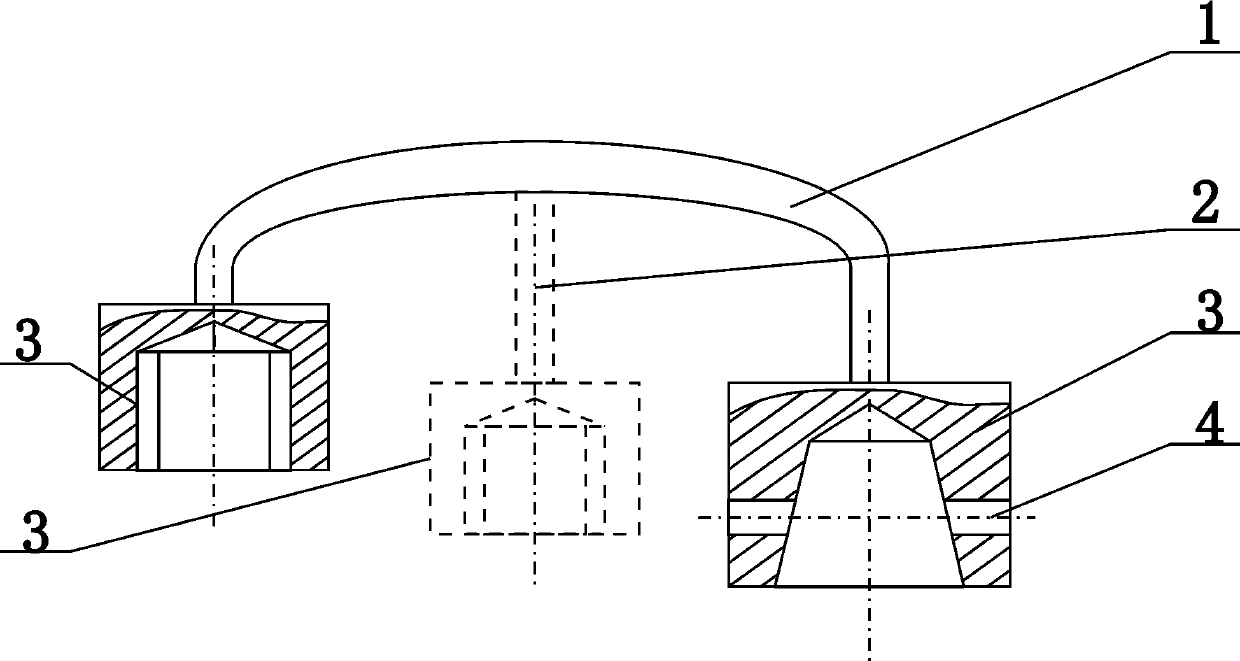

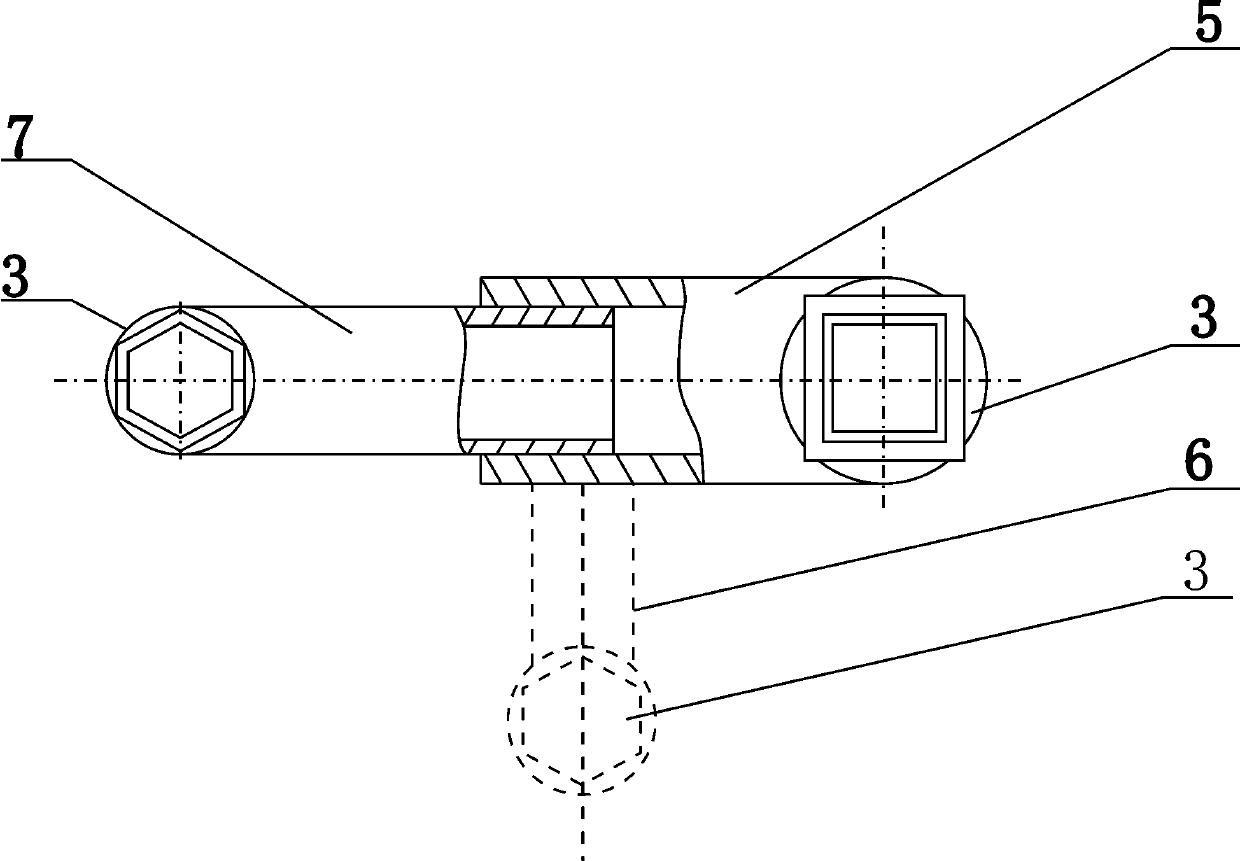

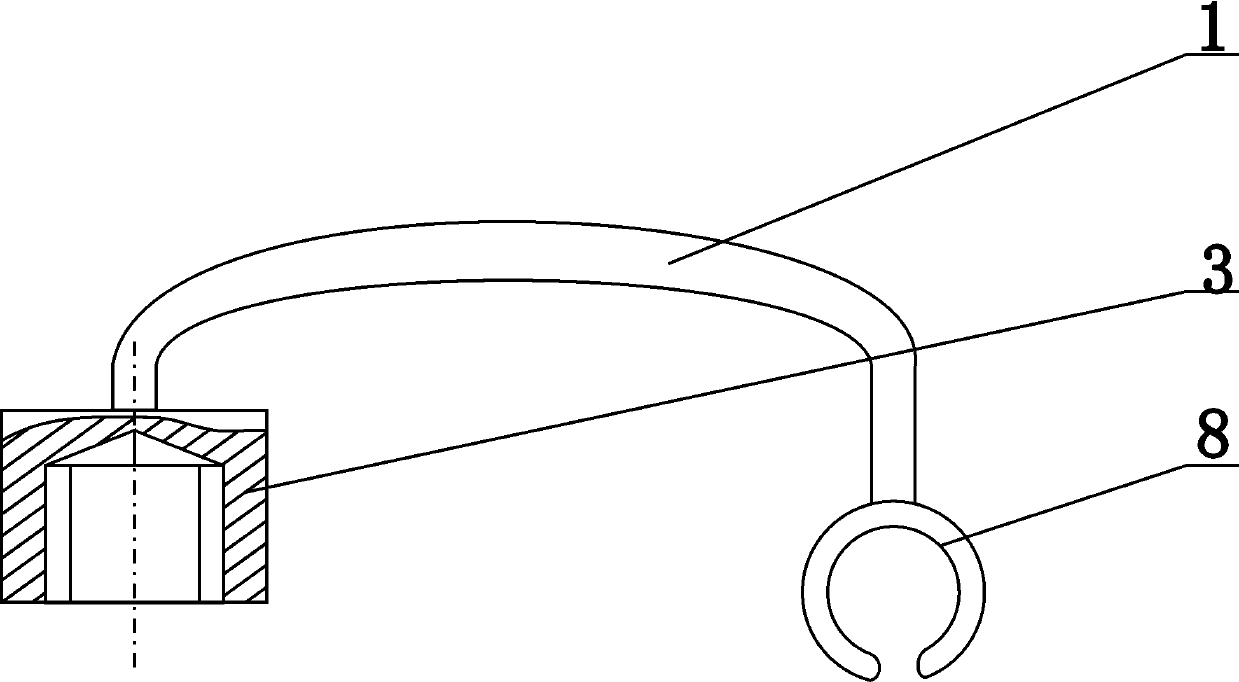

[0022] combined with Figure 1-4 Bolt anti-loosening conjoined caps, including connecting rod 1 and sleeve 3, sleeves 3 are made at both ends of connecting rod 1, and corresponding The through hole 4, the sleeve 3 is set on the outside of the bolt head of the rail fastener, and a corresponding through hole is provided on the bolt head, and the sleeve 3 is fixedly connected with the bolt head by an iron wire.

[0023] In the bolt anti-loosening one-piece cap, the through hole 4 is a light hole or a screw hole.

[0024] The bolt anti-loosening conjoined cap also includes a strut A2 arranged on one side of the connecting rod 1 and a fixing sleeve 3 made at the end of the strut 2 .

[0025] The bolt anti-loosening conjoined cap also includes a clamping ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com