Air duct of sprayer

A sprayer and blower technology, applied in the direction of spraying devices, etc., can solve the problems of low working efficiency of the sprayer and loose bolts, etc., and achieve the effects of reducing vibration, avoiding desoldering of welding joints, and avoiding loosening of bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A kind of embodiment of sprayer air cylinder of the present invention will be further described below in conjunction with accompanying drawing.

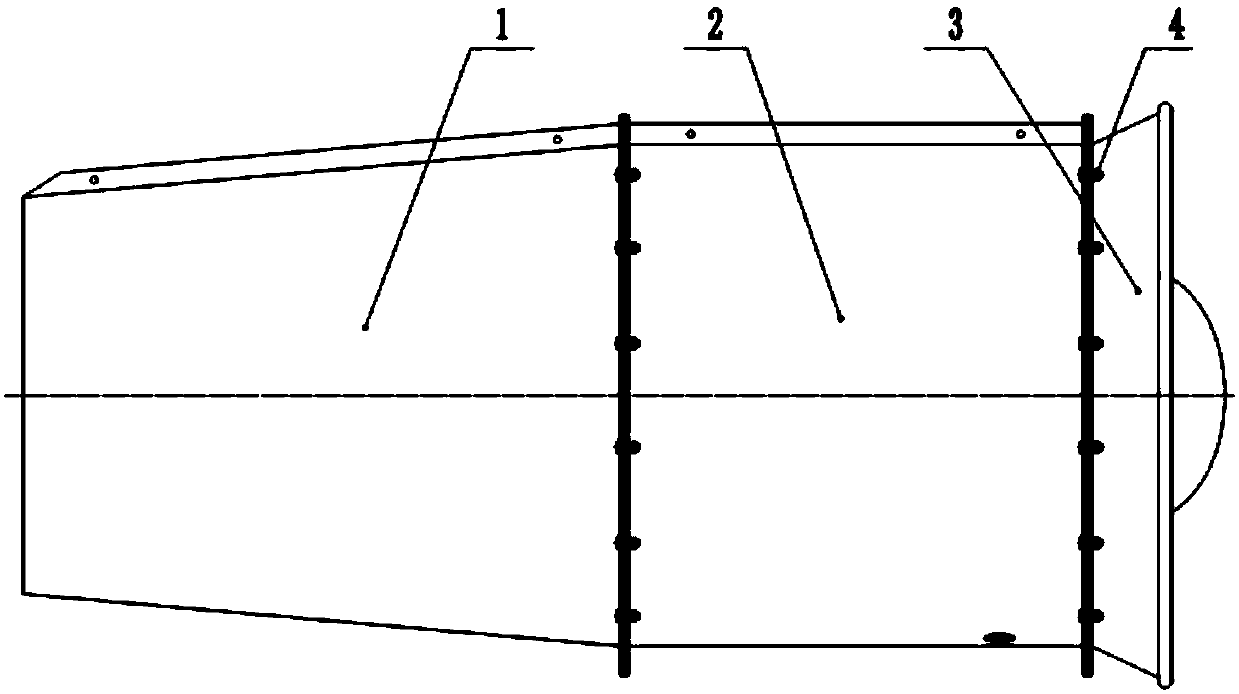

[0025] Embodiment one of the sprayer air duct of the present invention: as figure 1 As shown, the air cylinder of the sprayer consists of three parts: the front cylinder 1, the middle cylinder 2, and the rear cylinder 3, which are sequentially connected from left to right through corresponding flanges. Cylindrical, the rear tube 3 is a trumpet shape with a small left end and a large right end, and the front tube 1, the middle tube 2, and the rear tube 3 have the same axis.

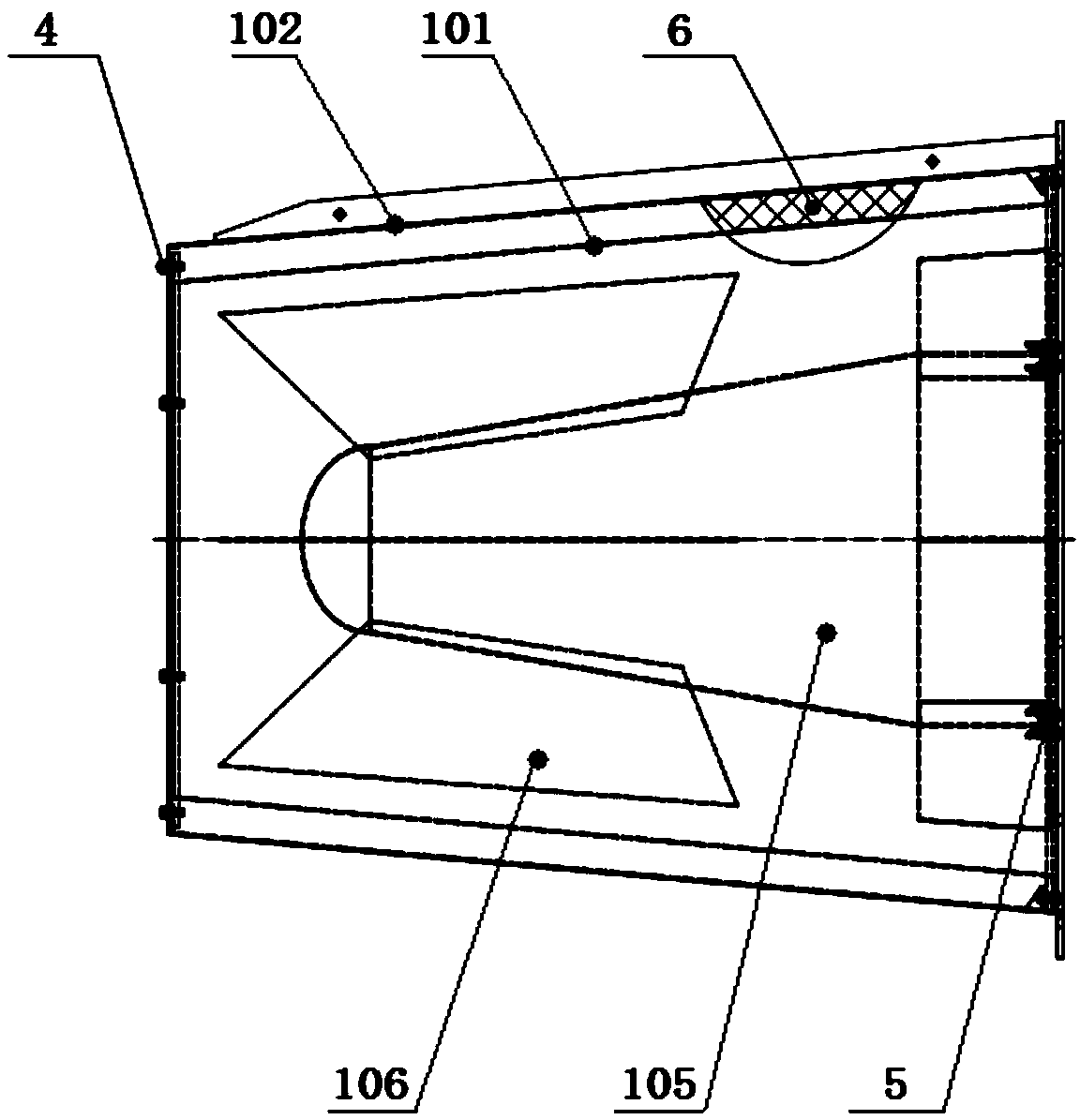

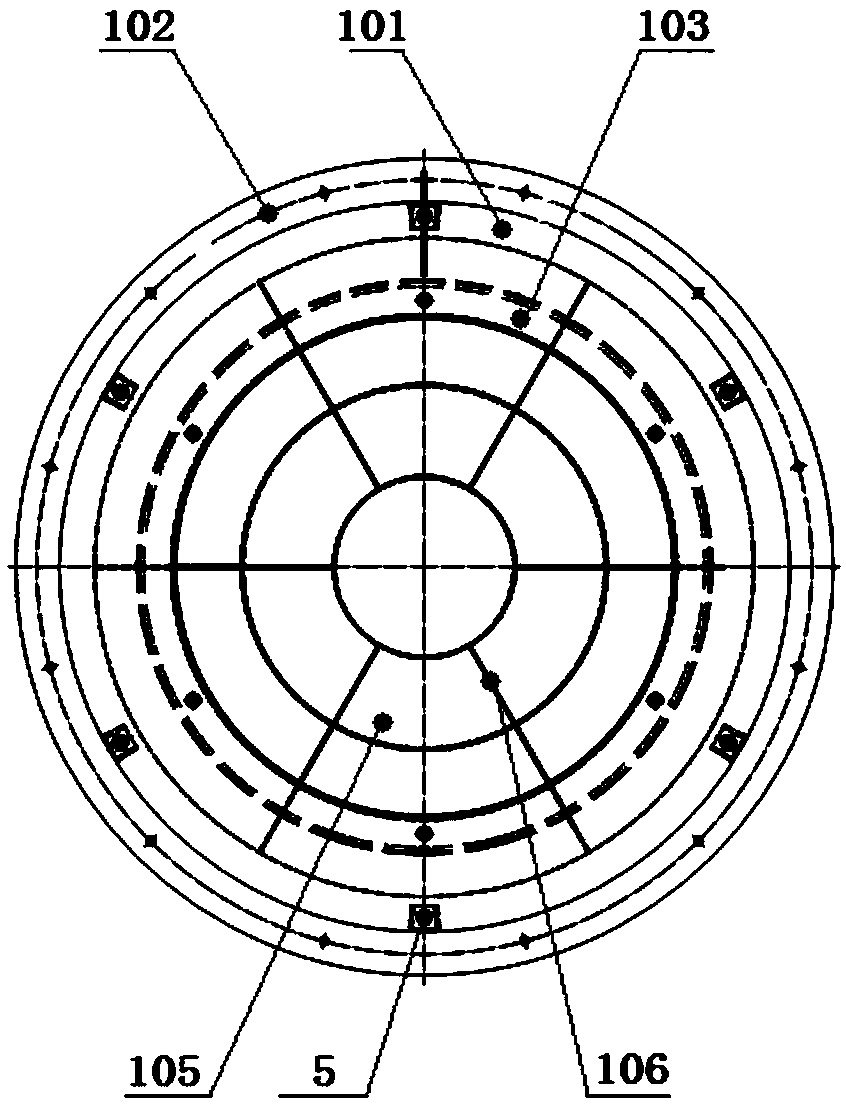

[0026] Such as Figure 6 As shown, the middle cylinder 2 is composed of a middle inner cylinder 201 and a middle outer cylinder 202. The middle inner cylinder 201 is formed by rolling a metal orifice plate into a main cylinder body and a taper sleeve 204 welded at the right end of the main cylinder body. The middle inner cylinder 201 and the A hollow cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com