Bolt assembly with locking function

A technology of bolt components and functions, which is applied in the field of anti-loosening bolt components, can solve the problems of reduced anti-loosening effect, processing of fixing frame, working hours and working hours, etc., and achieves the effect of easy separation and prevention of bolt loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

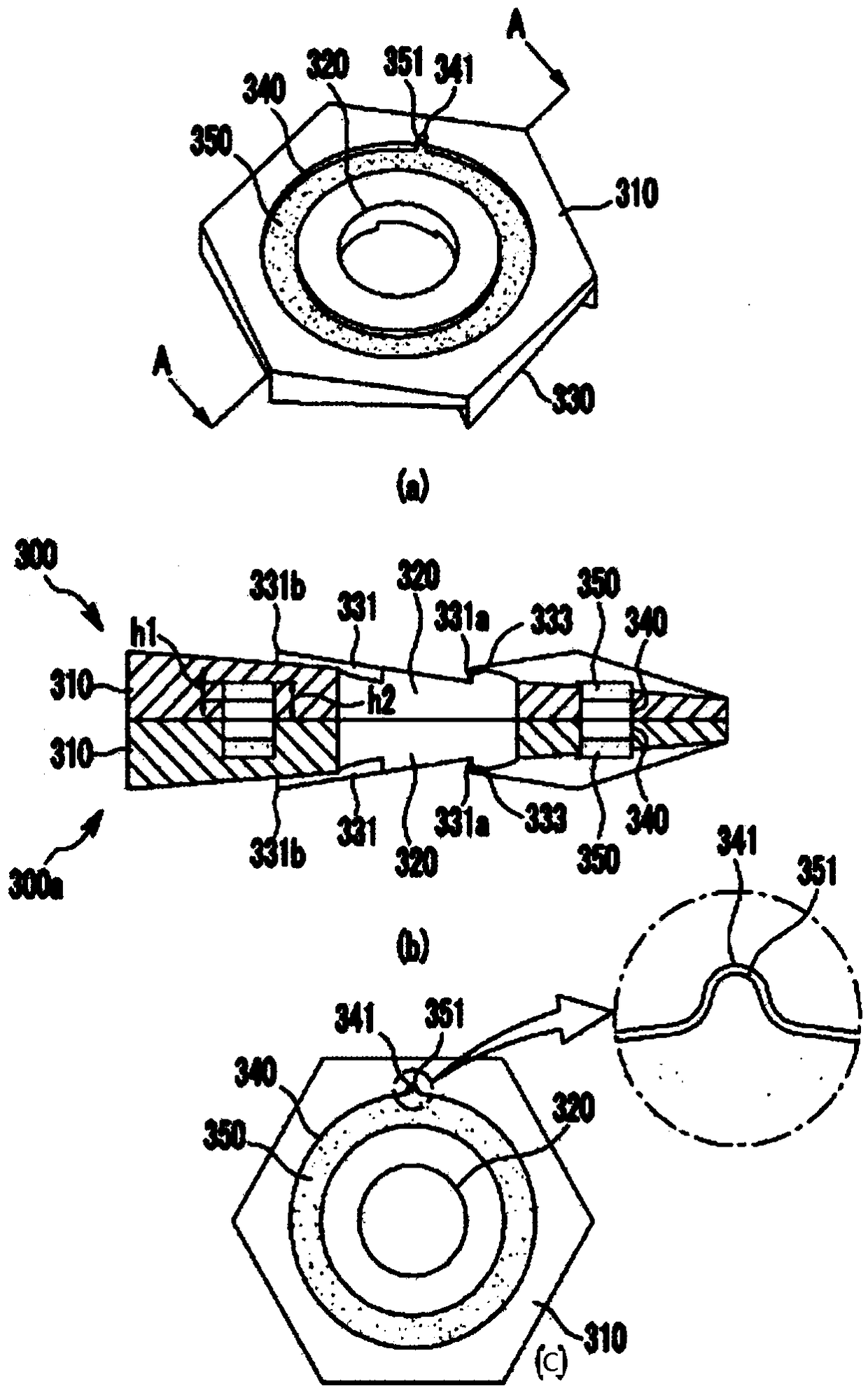

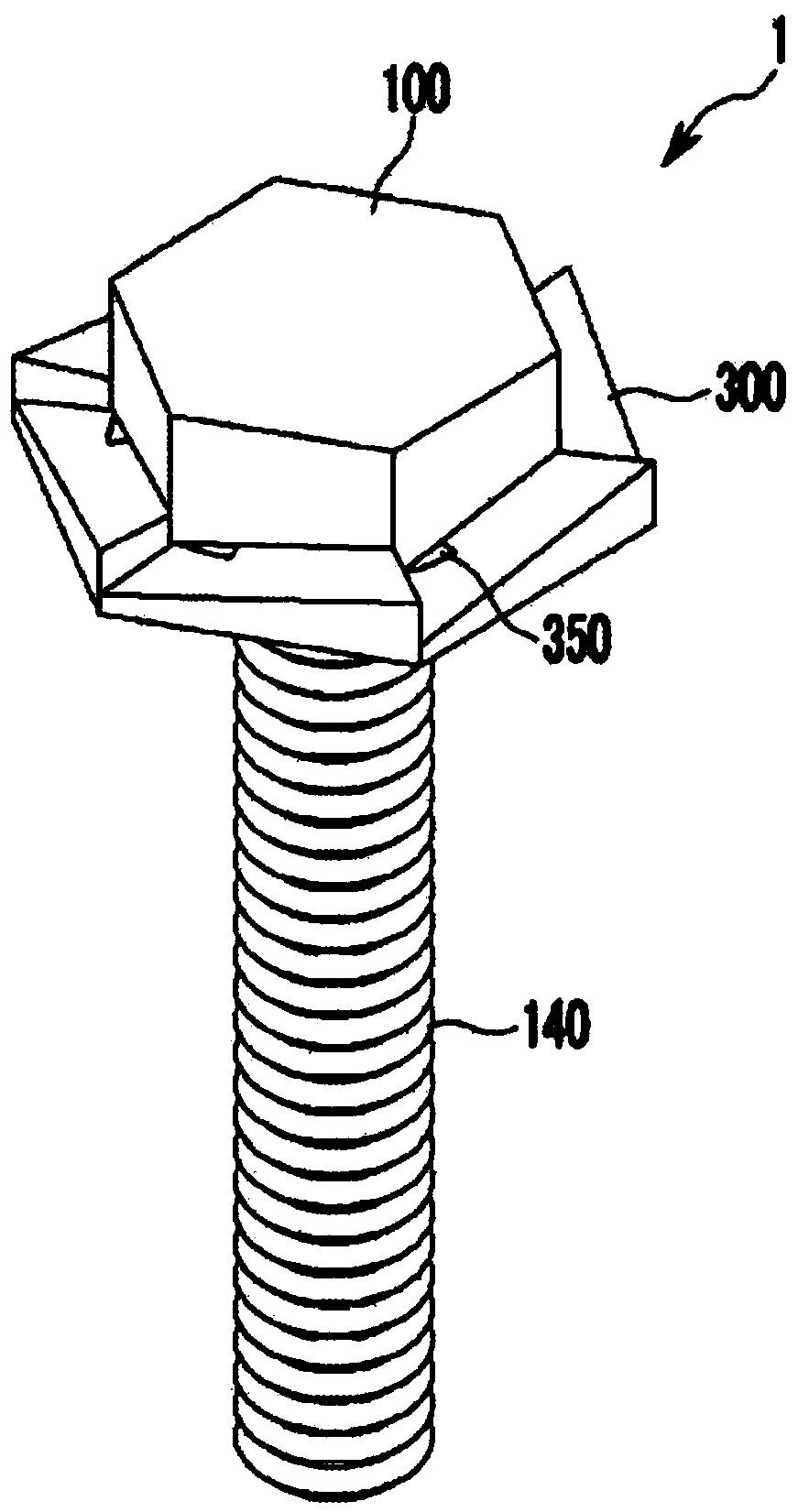

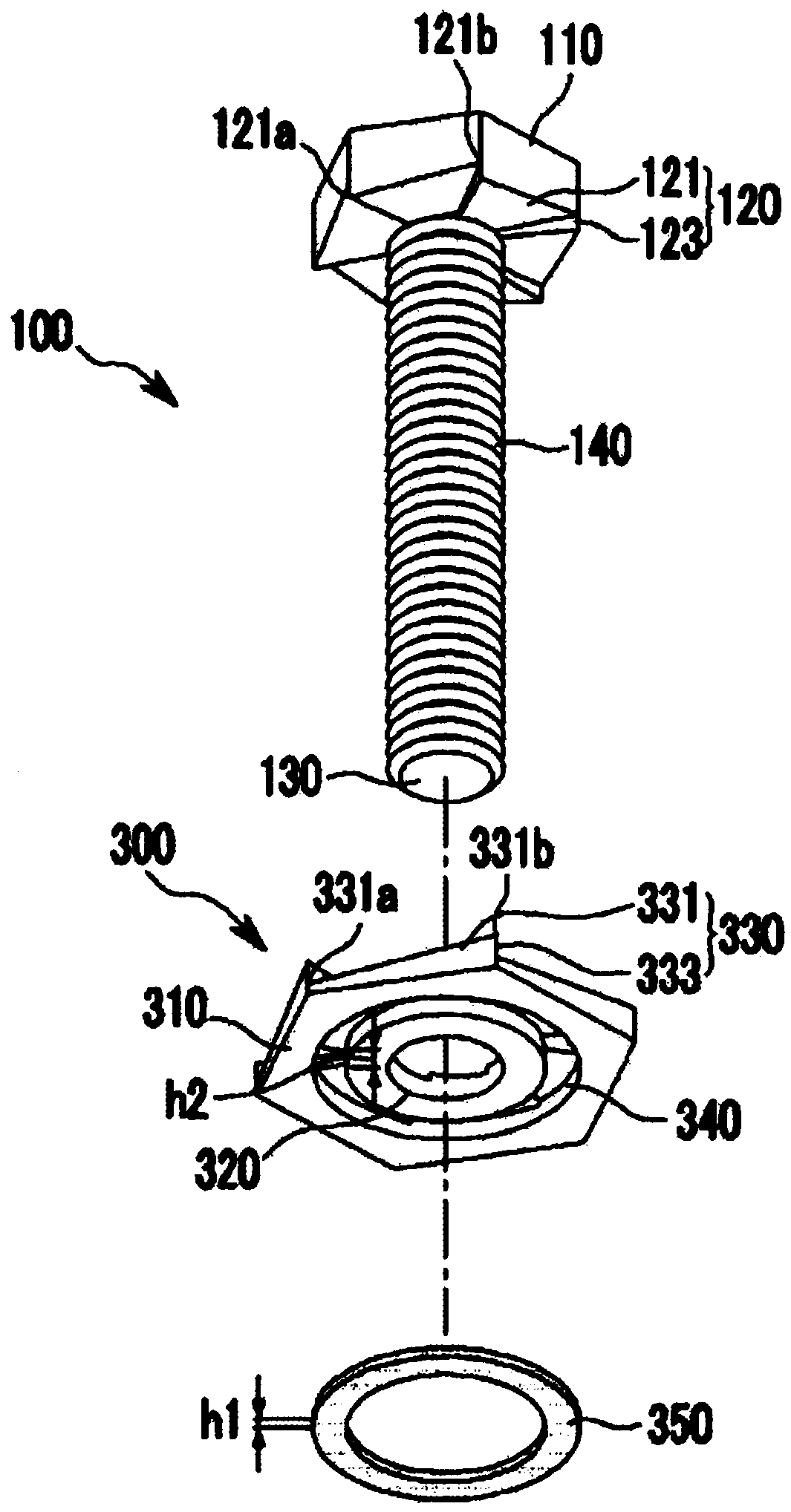

[0030] In order to fully understand the present invention, preferred embodiments of the present invention will be described with reference to the accompanying drawings. The embodiments of the present invention can be changed in various forms, and the scope of the present invention should not be construed as being limited to the embodiments described in detail below. This embodiment is provided to more completely describe the present invention to those skilled in the art. Therefore, in order to more clearly emphasize the content of description, the shapes of components in the drawings and the like may be enlarged and shown. Also, it should be noted that the same components are sometimes denoted by the same reference numerals in each drawing. Detailed descriptions of well-known functions and configurations that may obscure the gist of the present invention are omitted.

[0031] figure 1 It is a perspective view showing the structure of the anti-loosening bolt assembly 1 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com