Lightweight high-strength motor base

A motor base, high-strength technology, applied in the direction of motors, electric components, electric vehicles, etc., can solve the problems of reduced speed, easy loosening of bolts, large reverse potential energy, etc., to improve stability, avoid loosening of bolts, and accelerate air flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

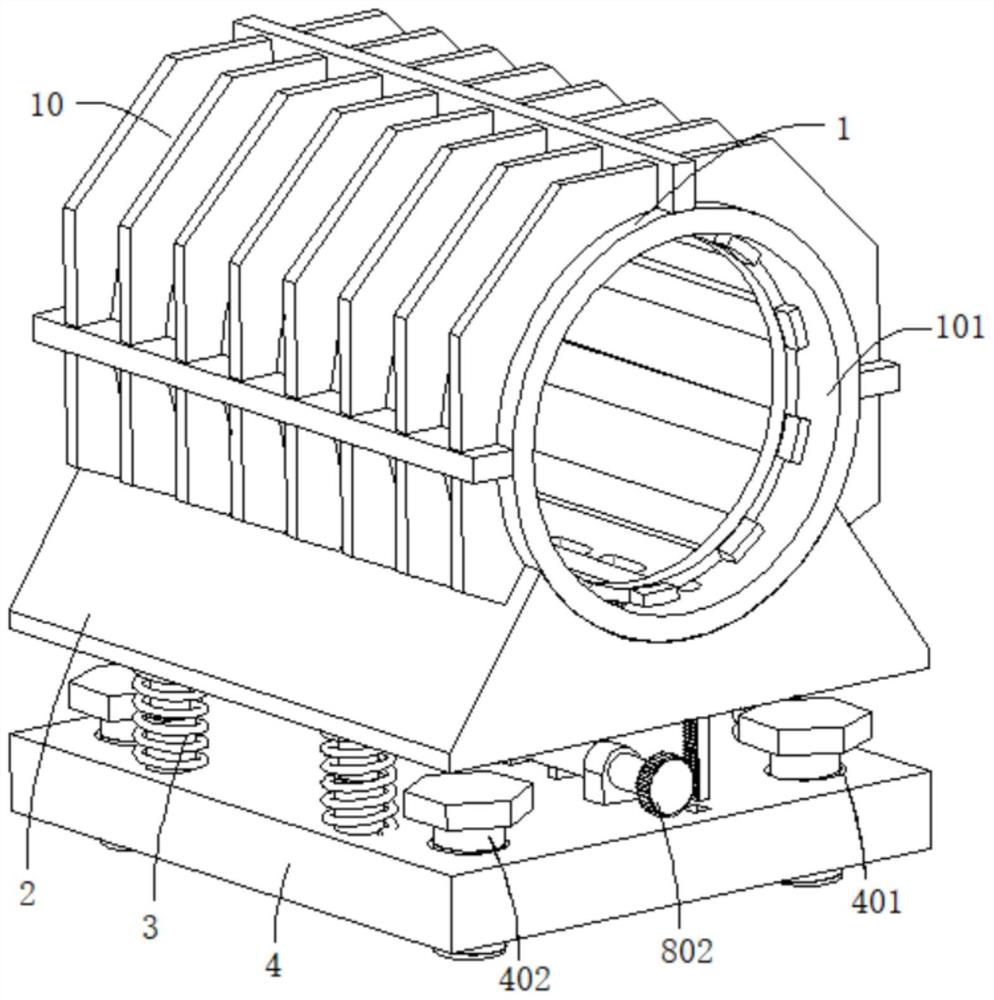

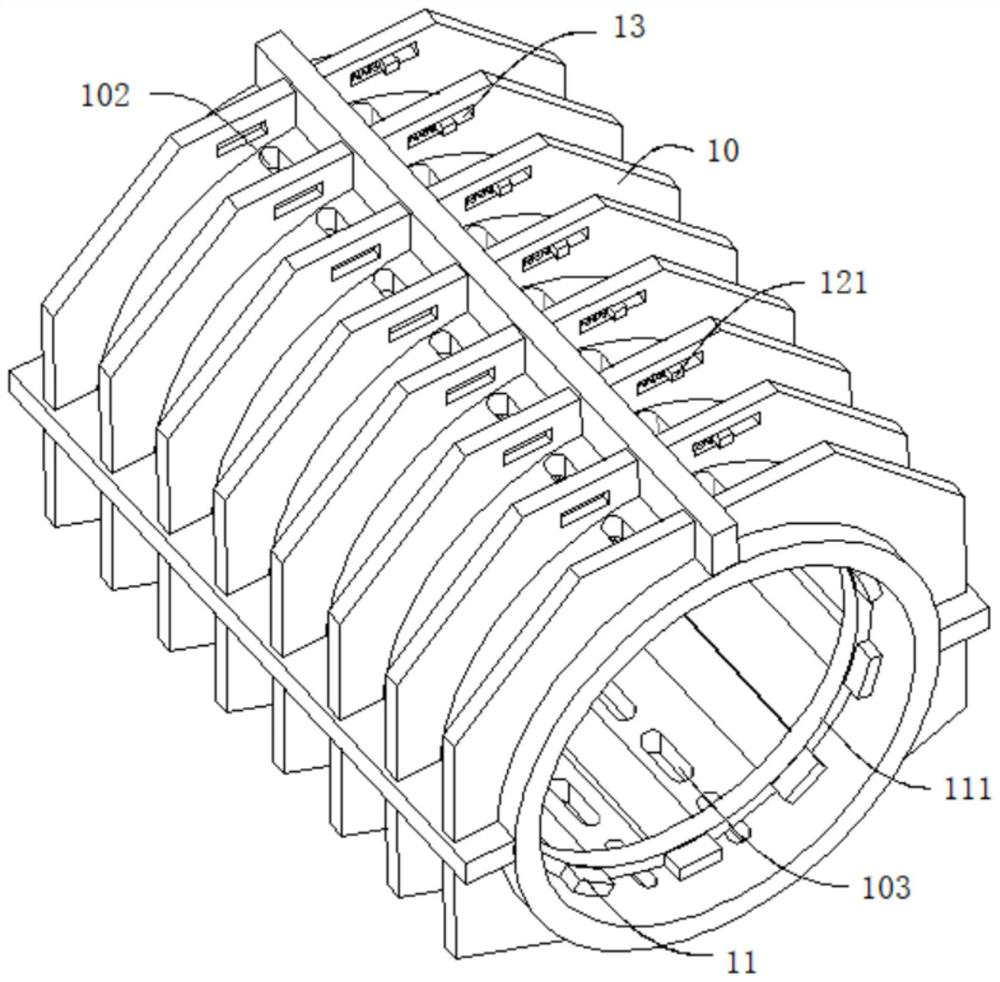

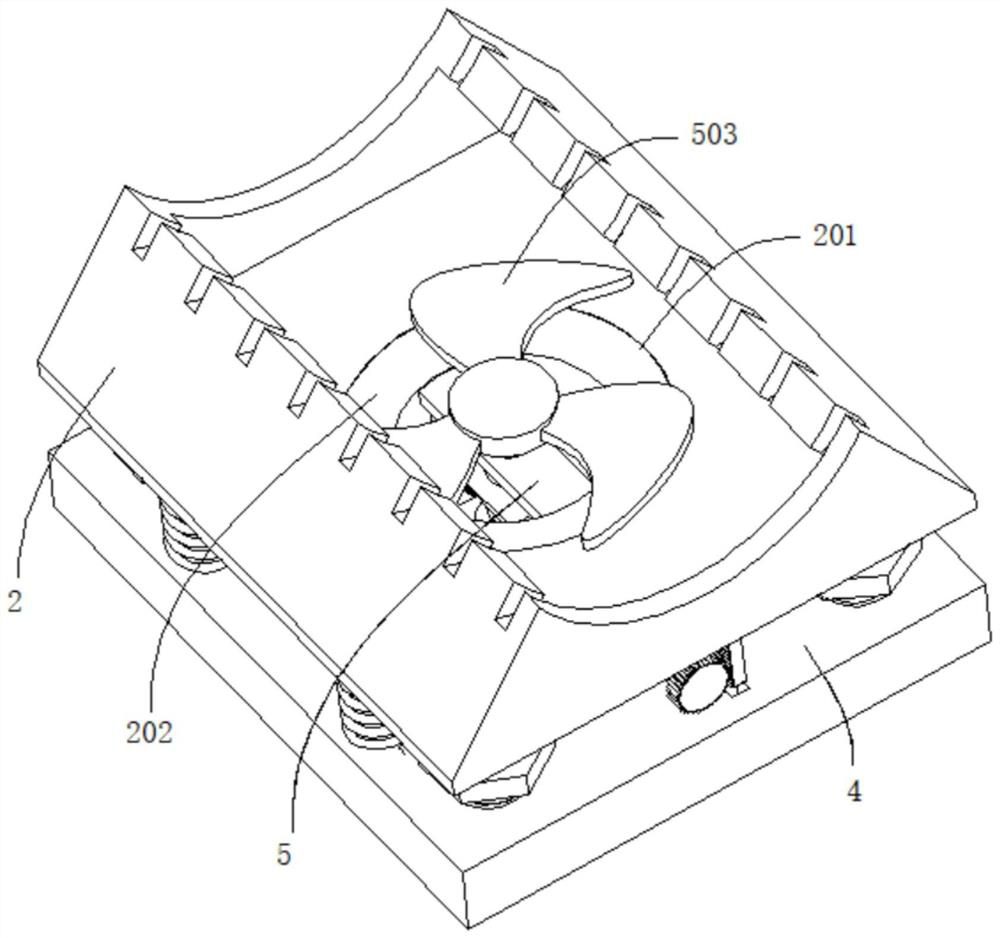

[0036] refer to figure 1 , figure 2 , image 3 and Figure 4 , a lightweight and high-strength motor base, including a protective shell 1, a mounting cavity 101 for placing a stator is arranged in the protective shell 1, and an air inlet 102 and an air outlet 103 are respectively opened at the top and bottom of the protective shell 1. The air inlet 102 is provided with a filter screen, the protective shell 1 is provided with a cleaning component for cleaning the filter screen, the bottom wall of the protective shell 1 is connected with a support shell 2, the support shell 2 and the air outlet 103 are communicated with each other, and the support shell 2 A heat dissipation assembly is arranged inside, a plurality of elastic telescopic rods 3 are connected to the bottom wall of the support shell 2, and a base 4 is connected to the end of the elastic telescopic rod 3 away from the support shell 2, and the base 4 is provided with a drive for driving the heat dissipation assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com