Looseness proof structure of bolts on water pump pipeline

A water pump pipe, anti-loosening technology, applied in the direction of bolts, screws, nuts, etc., can solve the problems of bolt assembly loosening, pipeline leakage, etc., and achieve the effect of avoiding bolt loosening and good anti-seismic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

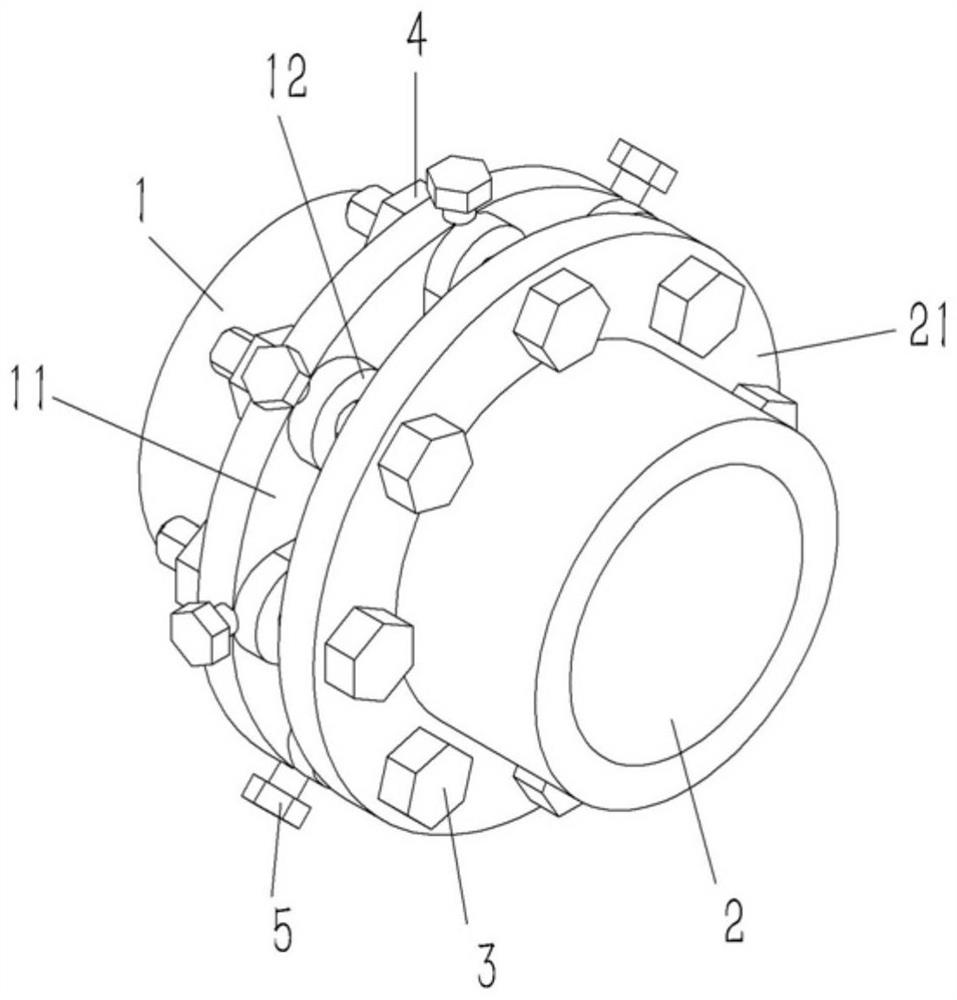

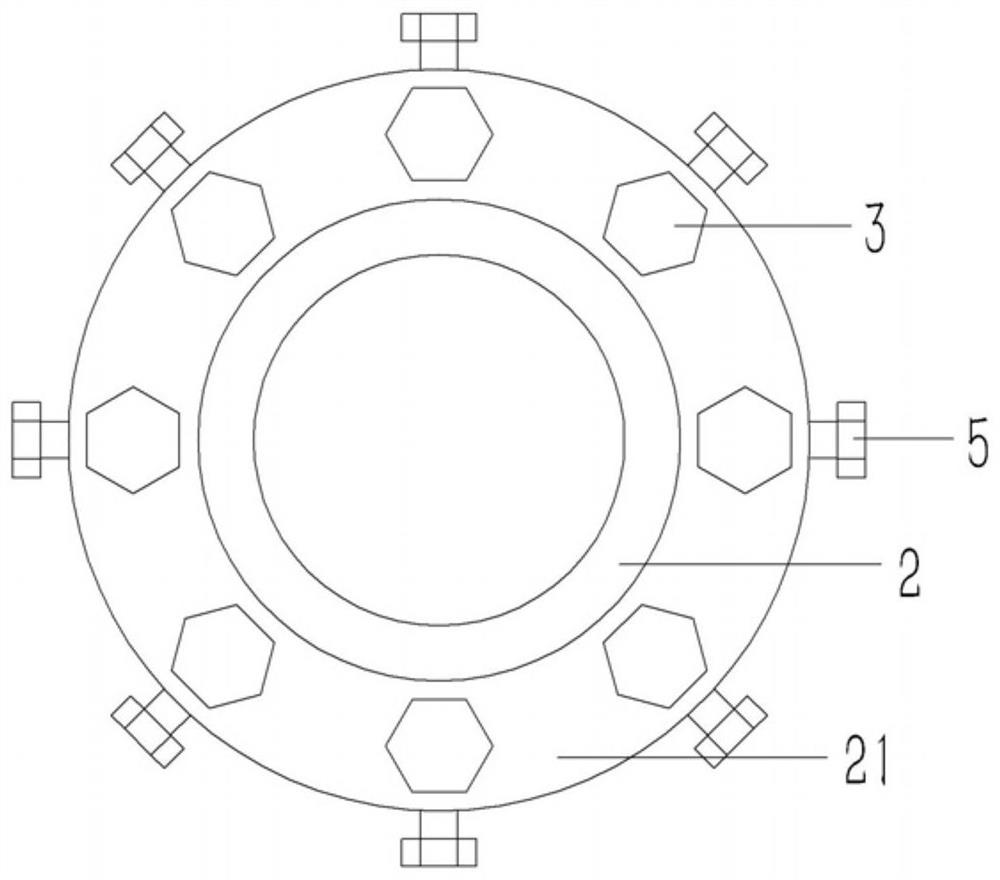

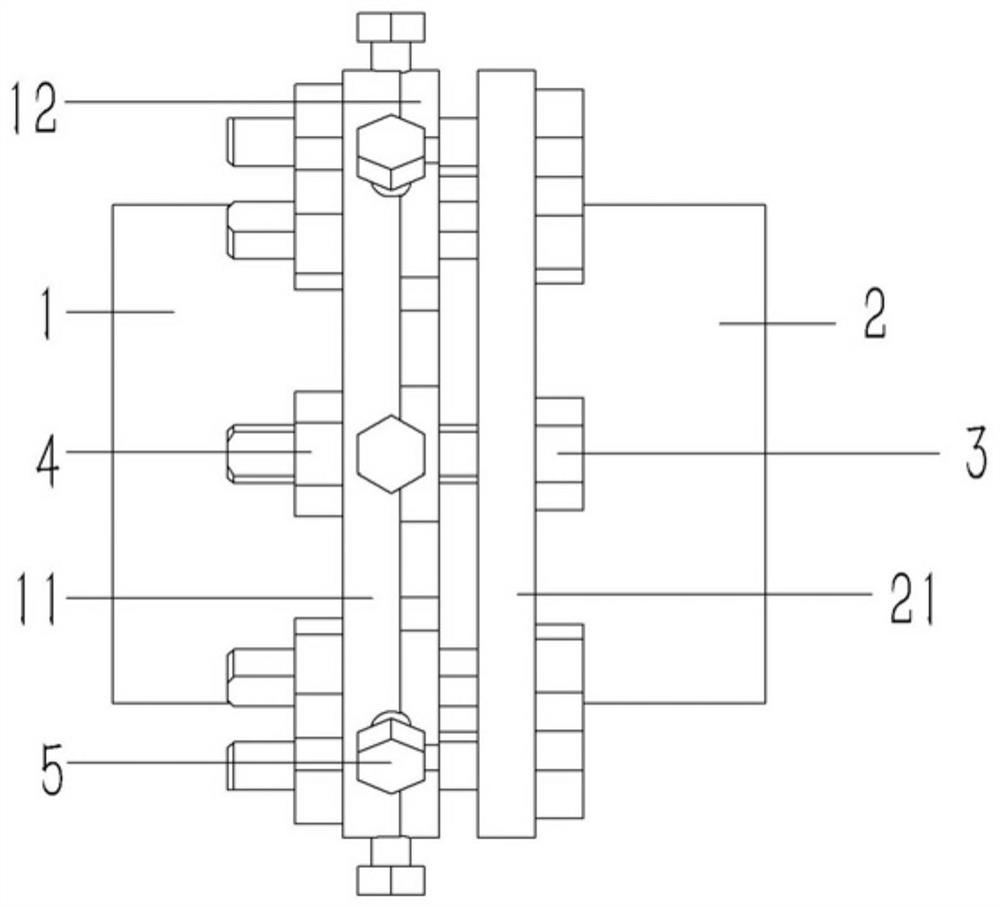

[0018] Example: see Figures 1 to 4 As shown, an anti-loosening structure for bolts on a water pump pipeline includes a first water pipe 1 and a second water pipe 2, and the outer walls of the first water pipe 1 and the second water pipe 2 near the ends are formed with a first flange 11 and a second water pipe respectively. Two flanges 21, the first flange 11 is formed with several protrusions 12 on the end surface close to the second flange 21, and the positioning holes 13 passing through the first flange 11 are formed on the protrusions 12, and the inner wall of the upper end of the positioning holes 13 There are threaded holes 14 through the outer wall of the second flange 21 formed on the top, and several bolt through holes 22 opposite to the positioning holes 13 are formed on the second flange 21, and the end surface of the second flange 21 is against a tight The fastening bolt 3 is formed with a D-shaped stud 31 on the fastening bolt 3. The stud 31 passes through the bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com