Clamping device for tea carding machine

The invention relates to a technology of a tea strip organizer and a clamping device, which is applied in the field of tea equipment, and can solve the problems of tea pouring and the unstable amplitude of the strip organizer, and achieve the effect of stable amplitude.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

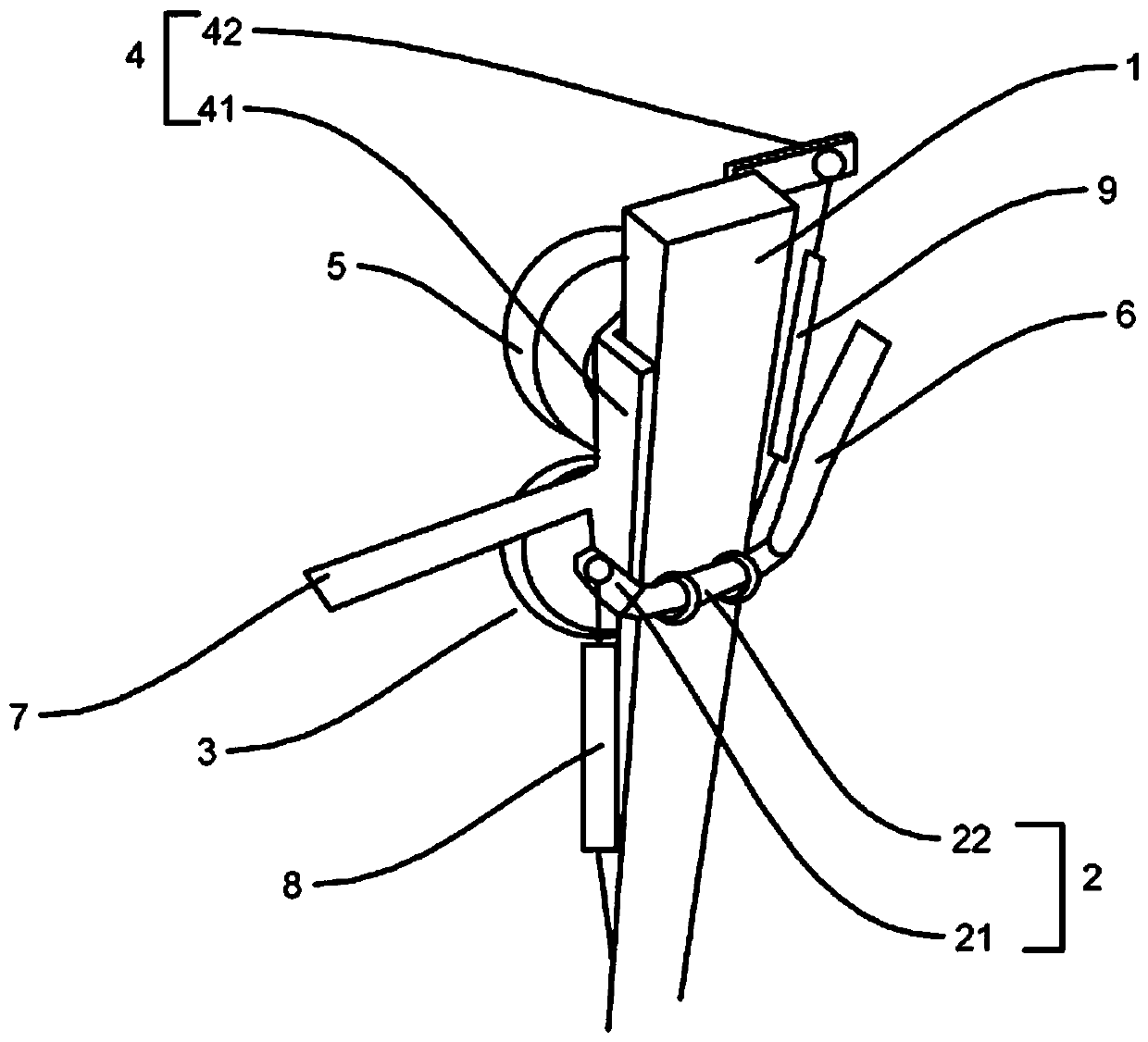

[0018] see figure 1 , the present invention is a kind of clamping device used for tea slivers, used to be fastened on the body, comprising: a bracket 1; a first fixed wheel 3, fixed on the bracket 1; a reset plate 4, hinged On the bracket 1; a second fixed wheel 5, fixed on the reset plate 4, used to be driven to the clamping position or the loosening position by the rotation of the reset plate 4, the clamping position is the second fixed wheel 5 and the first fixed The position where the width of the fastening channel enclosed between the wheels 3 is relatively small, and the loosening position is the position where the width of the fastening channel enclosed between the second fixed wheel 5 and the first fixed wheel 3 is relatively large; The elastic member 9 is used to produce the ability to drive the reset plate 4 to rotate so that the second fixed wheel 5 is in the released position; and a locking member 2 is used to press the second fixed wheel 5 in the clamping position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com