Wire spool of 3D printer

A technology of 3D printers and winding reels, applied in the field of 3D printing, can solve problems such as the inability to guarantee the normal transmission of multi-color materials and affect product quality, and achieve the effects of low cost, strong practicability, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

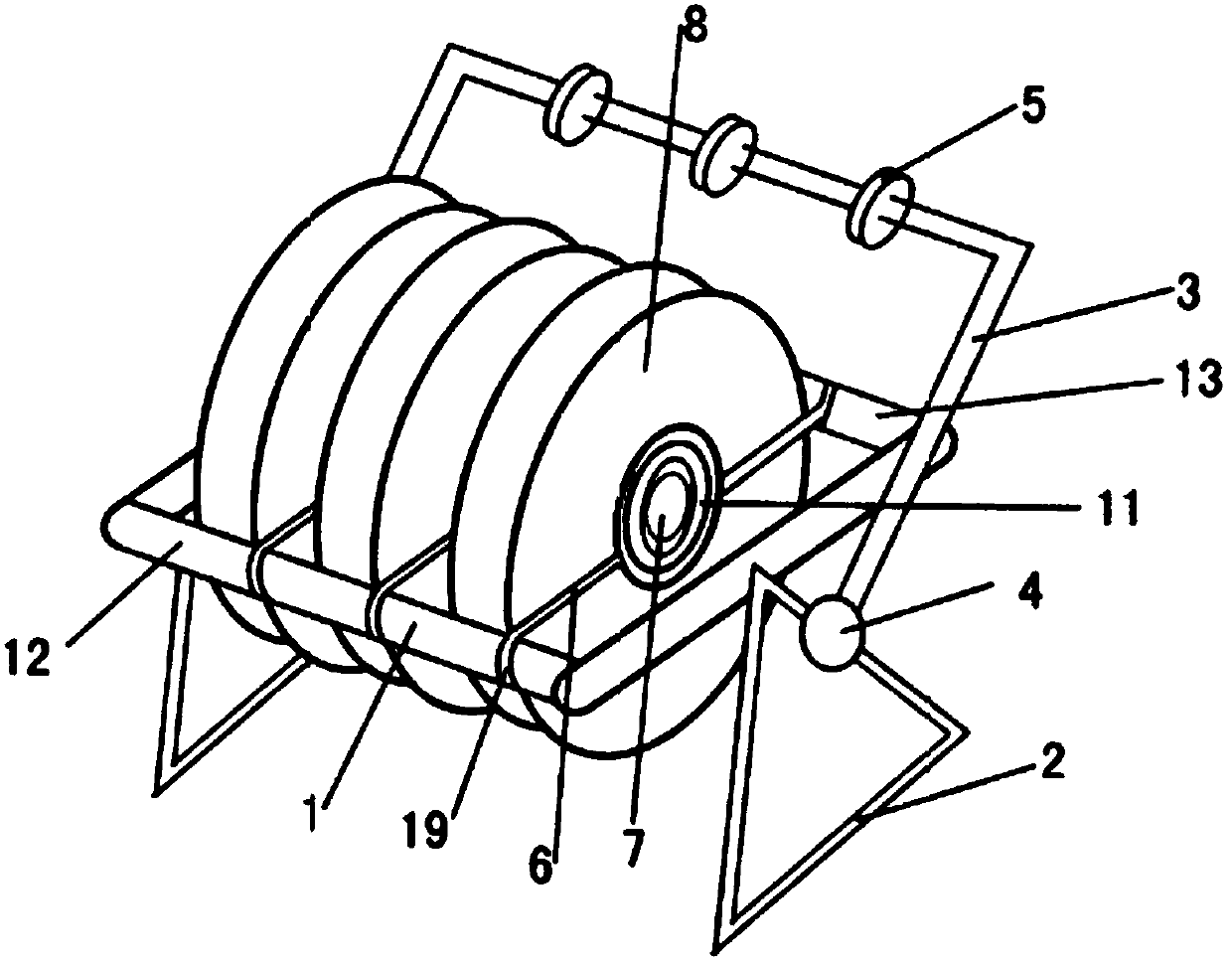

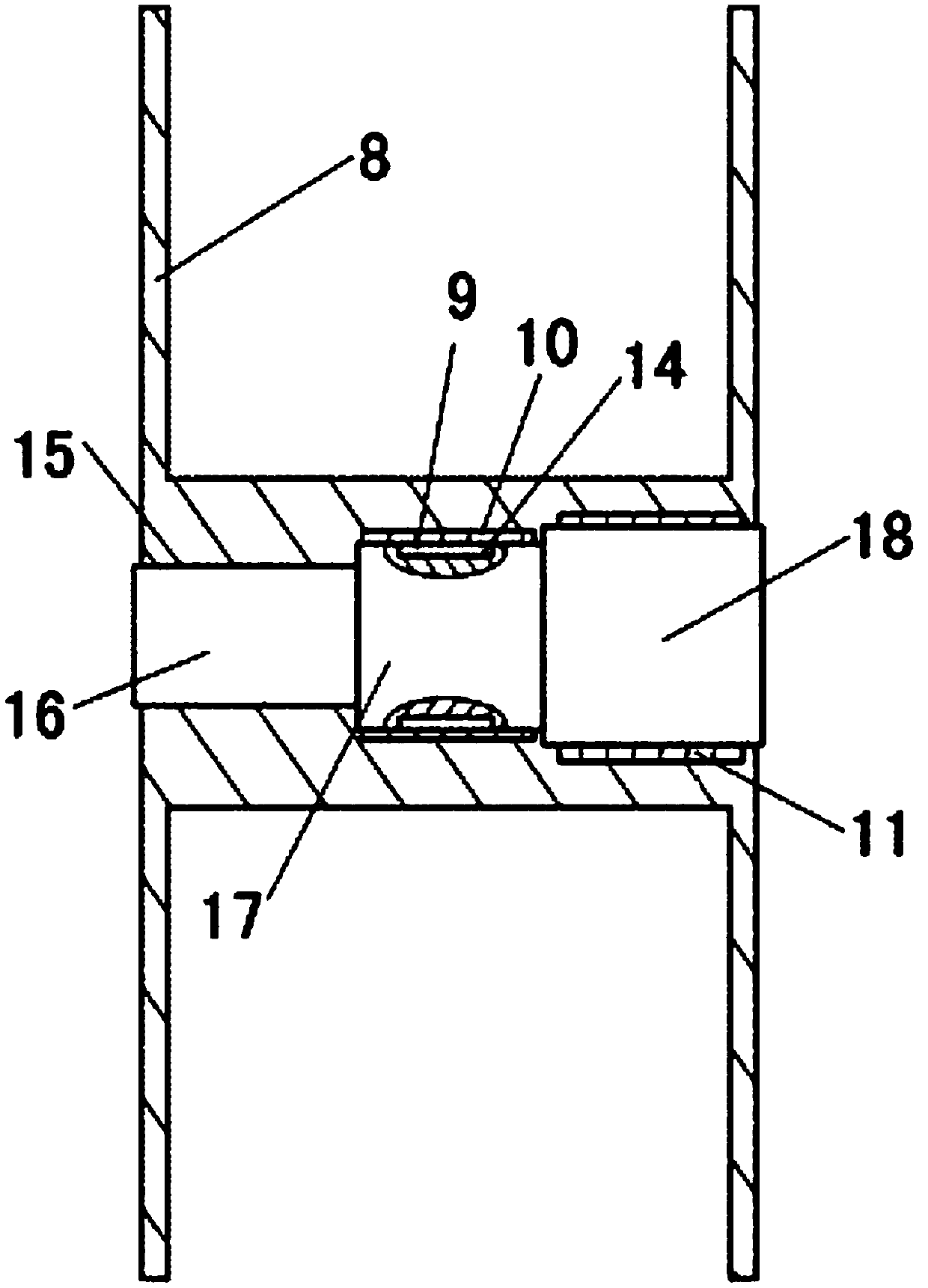

[0020] refer to Figure 1-2 , a 3D printer winding reel described in this specific embodiment, including a bracket 1, a tripod 2, a roller frame 3, an angle adjustment device 4, a guide roller 5, a spacer 6, a rotating shaft 7, a turntable 8, Magnets 9, iron rings 10 and bearings 11, a tripod 2 is arranged at both ends of the bracket 1, a roller frame 3 is arranged on one side of the tripod 2, the roller frame 3 is connected with the tripod 2 through an angle adjustment device 4, and the roller frame 3 Three guide rollers 5 are evenly distributed on the top, and the bracket 1 includes a track A12 and a guide rail B13 parallel to each other. There are three spacers 6 connected between the track A12 and the guide rail B13, and the rotating shaft 7 is installed on the spacer through a bearing 11. 6, a detachable turntable 8 is set on the rotating shaft 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com