Mold pressing mechanism of full-automatic disc shoe upper injection molding machine

An injection molding machine, disc-type technology, applied in the field of compression molding mechanism, can solve problems such as impractical, time-consuming and labor-consuming, and dangerous to operators, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

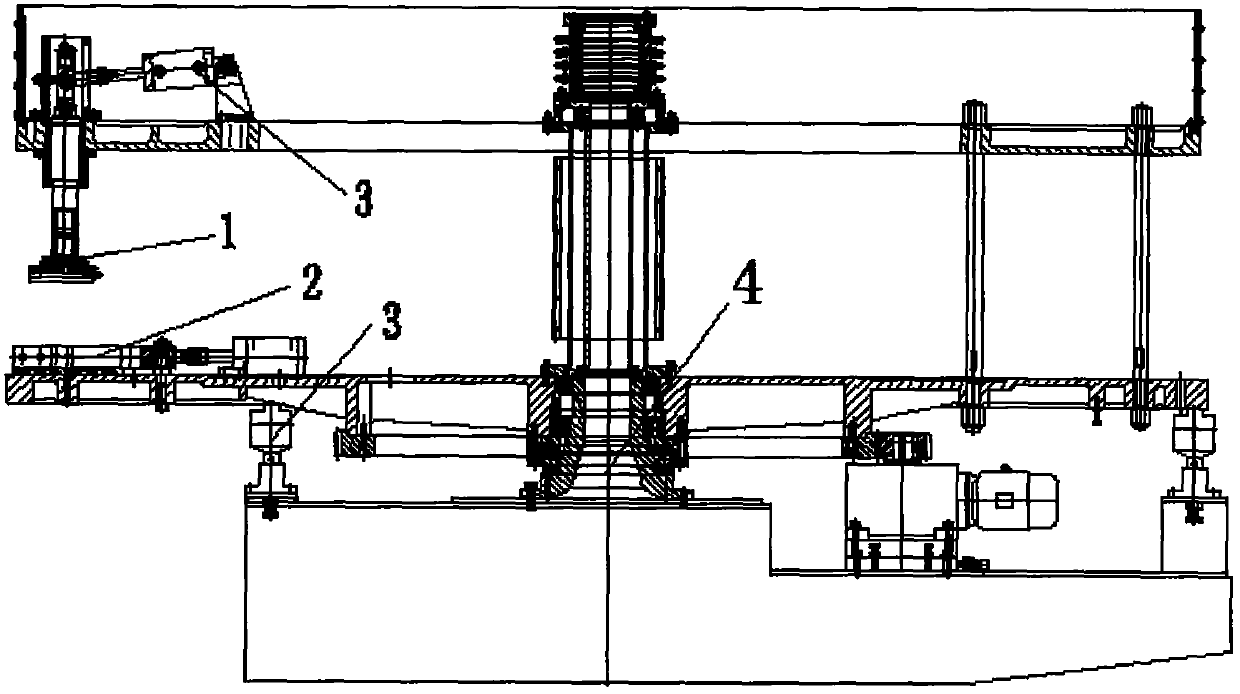

[0009] Such as figure 1 As shown, a compression molding mechanism of a fully automatic disc-type footwear upper injection molding machine includes an injection molding machine, and the injection molding machine includes an injection molding mechanism and a workbench, and the compression molding mechanism is provided on the workbench. The platform includes an upper disc and a lower disc, and the upper disc and the lower disc cooperate with the motor drive through the valve core 4. The mold pressing mechanism includes an upper pressing mechanism 1 and a lower pressing mechanism 2, and the upper pressing mechanism 2 The pressing mechanism 1 is arranged at the lower end of the upper disc, and the described lower pressing mechanism 2 is arranged at the upper end of the lower disc. The position of the described upper pressing mechanism 1 corresponds to that of the lower pressing mechanism 2. The hydraulic press 3 can control the upward and downward movement of the upper pressing mec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap