A low-impact separation nut based on slow release of preload

A technology of separating nut and low impact, applied in mechanical equipment, fixtures, etc., can solve the problem of large impact of separating nut, and achieve the effect of prolonging release time and overcoming large impact response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

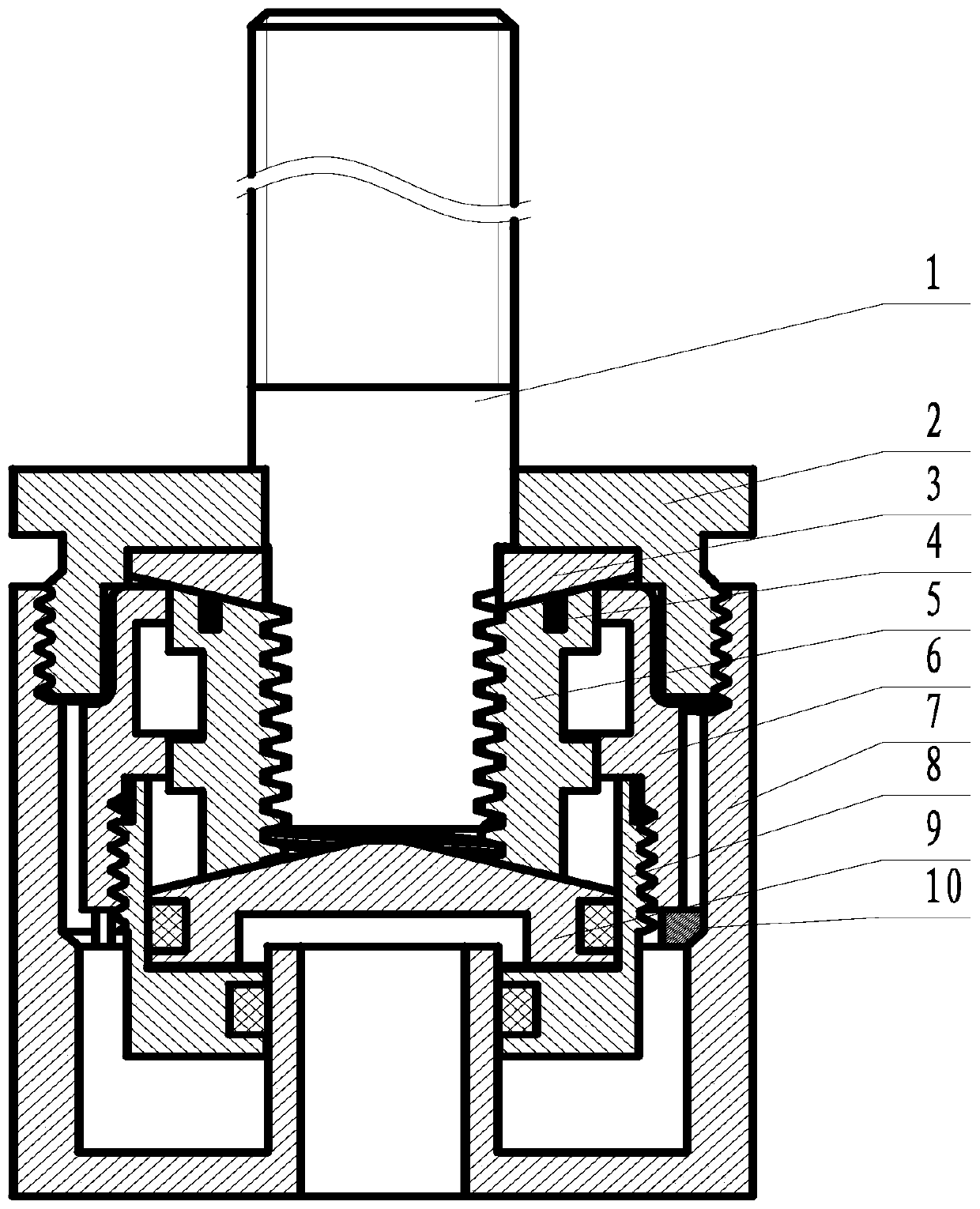

[0036] A low-impact separation nut based on slow release of pretightening force, the separation nut includes: a cover 2 and a housing 7; the lower surface of the housing 7 is provided with a hollow cylinder protruding inward;

[0037] The cover 2 is matched and fixed with the housing 7, and a cavity structure is formed between the cover 2 and the housing 7;

[0038] Inside the cavity structure are: bolts 1, stoppers 3, slow release rings 4, split nuts 5, hoops 6, pistons 8, piston discs 9 and retaining rings 10;

[0039] The center of the cover 2 is provided with a round hole, and the bolt 1 passes through the round hole in the center of the cover 2 and is matched and fixed with the split nut 5;

[0040] The stopper 3 is located between the lower surface of the cover 2 and the upper surface of the split nut 5;

[0041] The middle part of the upper surface of the split nut 5 is provided with a groove, and the slow release ring 4 is embedded in the groove of the split nut 5;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com