An adaptive hoop installation device and fastening method

An installation device and self-adaptive technology, applied in the direction of friction clamping detachable fasteners, connecting components, mechanical equipment, etc., can solve the problems of unstable installation, potential safety hazards, small adjustment range, etc., and achieve easy operation and Use, eliminate safety accidents, and reduce the effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

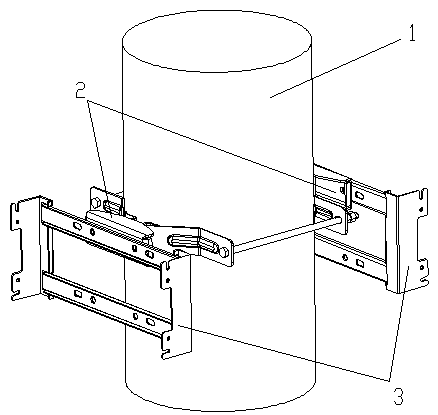

[0058] Such as figure 1 , image 3 and Figure 4 As shown, the adaptive hoop installation device includes a hoop 2 for tightening on the pile 1, and an installation base 3 for installing communication equipment, and the installation base 3 is connected to the hoop 2, in:

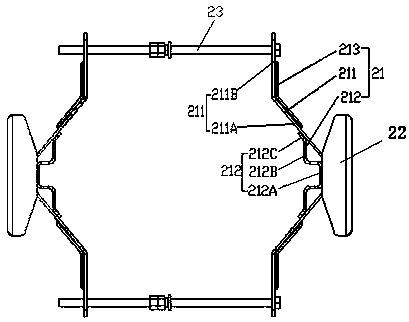

[0059] The hoop 2 includes two clamping parts 21 respectively arranged on the periphery of the pile 1, each of the clamping parts 21 includes two stirrups 211, and the two stirrups 211 are arranged obliquely to each other, and In the shape of a trumpet opening, the inclined section 211A of each stirrup 211 is straight, and the hoop 2 further includes a tension member 23 for pulling and locking the two clamping members 21 .

[0060] The installation base 3 is provided with an installation structure for connecting communication equipment.

[0061] The existing clamp has a circular arc clamp surface. When this clamp is used, the diameter of the clamp must correspond to the size of the pile to ensure that th...

Embodiment 2

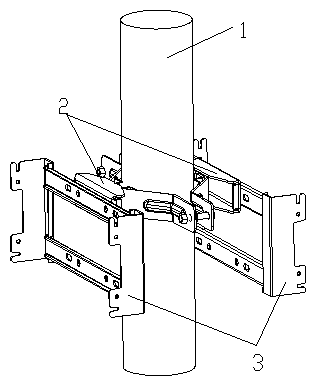

[0078] The self-adaptive hoop of this embodiment is suitable for piles of a larger size range, such as figure 2 The diameter of the pile 1 in is obviously smaller than in embodiment 1 figure 1 The diameter of pile 1 in .

[0079] The self-adaptive hoop structure of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0080] Such as figure 2 , image 3 and Figure 4 As shown, each clamping member 21 is provided with an internal hoop 212, which is installed at the intersection of the two stirrups 211, and the inner hoop 212 is provided with the hoop 211 The horn openings have the same opening direction, and the opening of the inner strap 212 is smaller than the horn opening.

[0081]As one of the implementations, the inner hoop 212 includes a right-angle groove section 212A, and a flat section 212B connected to both ends of the right-angle groove section 212A, and the flat section 212B is connected with the hoop 211 extending in the sam...

Embodiment 3

[0086] Such as figure 1 , image 3 and Figure 4 As shown, the fastening method of the adaptive hoop installation device, when using the adaptive hoop installation device as in Example 1 for fastening, the specific operation adopts the following steps:

[0087] a. Arrange the clamping part 21 on both sides of the pile 1, and install the tensioning part 23 on the clamping part 21 at the same time;

[0088] b. Use tensioning parts 23 to pull the clamping parts 21 on both sides of the pile 1, so that the clamping parts 21 move closer to the pile 1;

[0089] c. The inclined section 211A (straight section) of the stirrup 211 of the clamping member 21 is in contact with the pile 1;

[0090] d. Use fasteners to lock the tension member 23;

[0091] e. Connect the installation base 3 with the hoop 2, and fix the communication equipment on the installation base 3 through the installation structure.

[0092] The fastening method of this scheme can fix the self-adaptive hoop installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com