Wooden threaded pipe having homology restoration performance

A threaded pipe and wood technology, applied in the direction of pipe elements, furniture connections, pipes/pipe joints/fittings, etc., can solve the problems of cracks, expensive wooden threaded pipes, and reduced service life of wooden threaded pipes, etc. The effect of improving fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of the present patent will be described in further detail below in conjunction with specific embodiments.

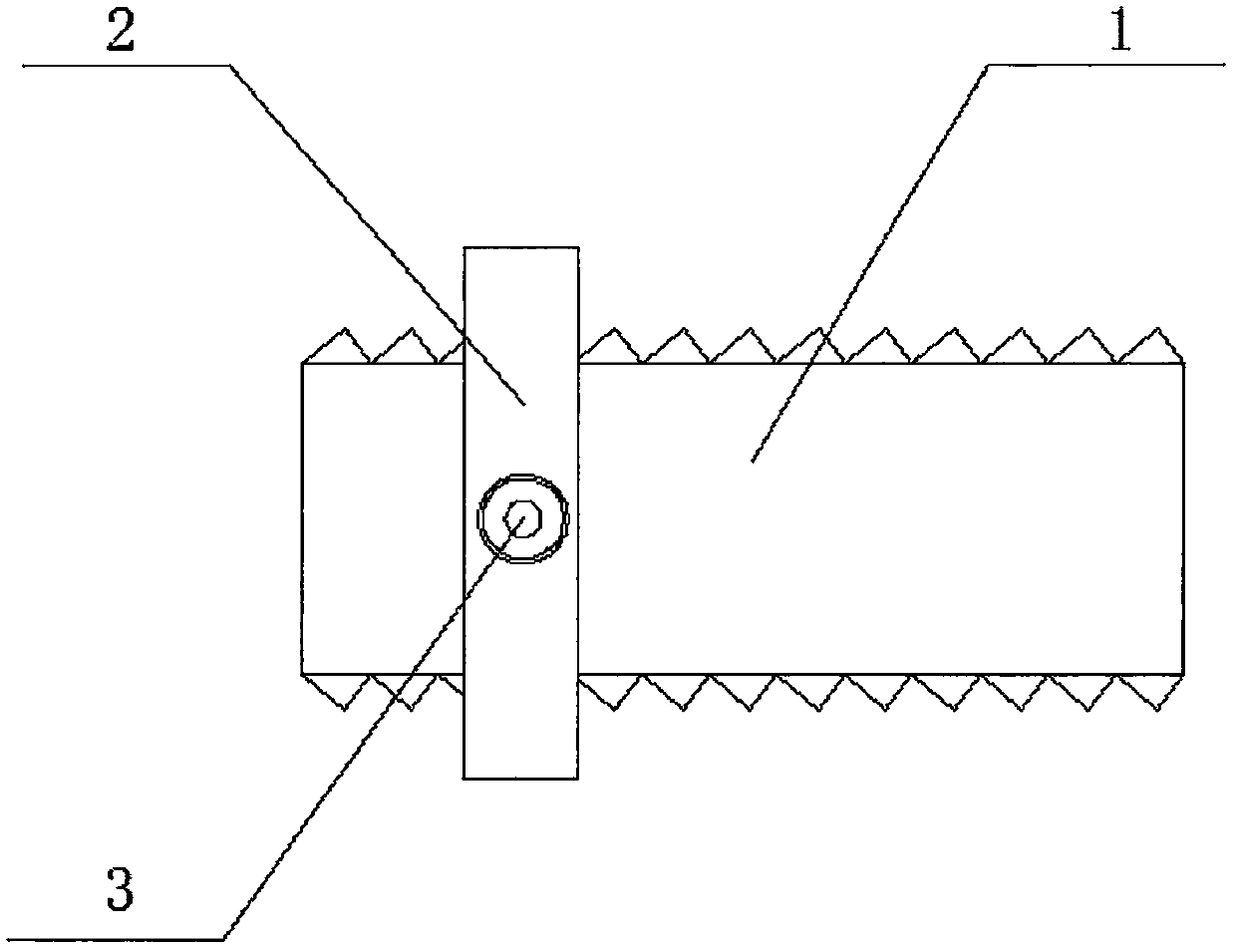

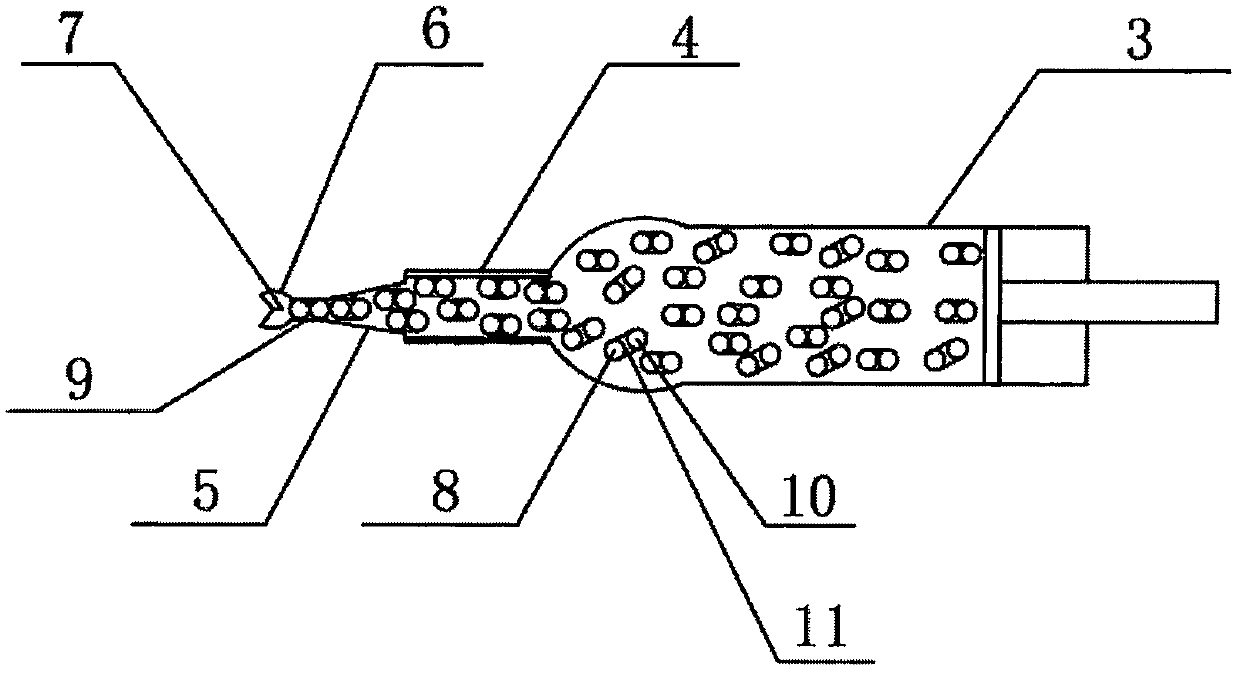

[0012] see figure 1 , 2 , a wooden threaded pipe with homologous repair performance, comprising a wooden threaded pipe 1, a nut 2 is screwed on the outer periphery of the wooden threaded pipe 1, the radial side wall of the nut 2 is provided with a screw hole, and the screw hole is threadedly connected with a leak trap device. The leak trapping device includes a connecting tube 4 screwed into a screw hole, and both ends of the connecting tube 4 are respectively provided with a syringe 3 and a needle 5 of integral structure. The syringe 3 and the needle 5 are filled with a film-coated repair capsule 11 . The repair capsule 11 contains a first film ball 8 and a second film ball 10 , the first film ball 8 contains a urea-formaldehyde resin adhesive, and the second film ball 10 contains lignin.

[0013] As a structure, the needle head 5 is pre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap