Guide rail assembly type light module

An assembled and guide rail technology, applied in the direction of lighting devices, fixed lighting devices, lighting auxiliary devices, etc., can solve the problems of unreasonable, unfavorable adjustment of light intensity, heavy workload, etc., and achieve adjustable light intensity and fast maintenance of lights Group, compact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

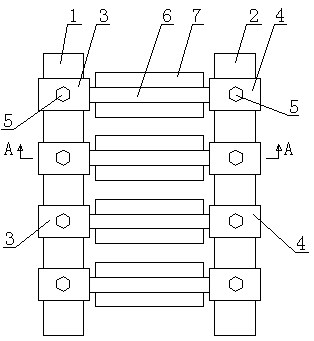

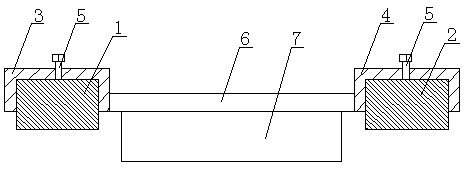

[0013] Such as Figure 1~2 As shown, a guide rail assembled lamp module includes a left guide rail 1 and a right guide rail 2, the left guide rail 1 and the right guide rail 2 are arranged parallel to each other, and the left guide rail 1 is covered with a plurality of sliding sleeves A3. The spacing between adjacent sliding sleeves A3 is equal, and the right guide rail 2 is covered with multiple sliding sleeves B4, the spacing between adjacent sliding sleeves B4 is equal, the sliding sleeves are concave parts, and the sliding sleeves are fastened on the top of the guide rail. There is a locking screw 5 on the top of the top, and the locking screw 5 passes through the sliding sleeve and is pressed against the guide rail. A mounting plate 6 is fixed between the sliding sleeve A3 and the sliding sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com