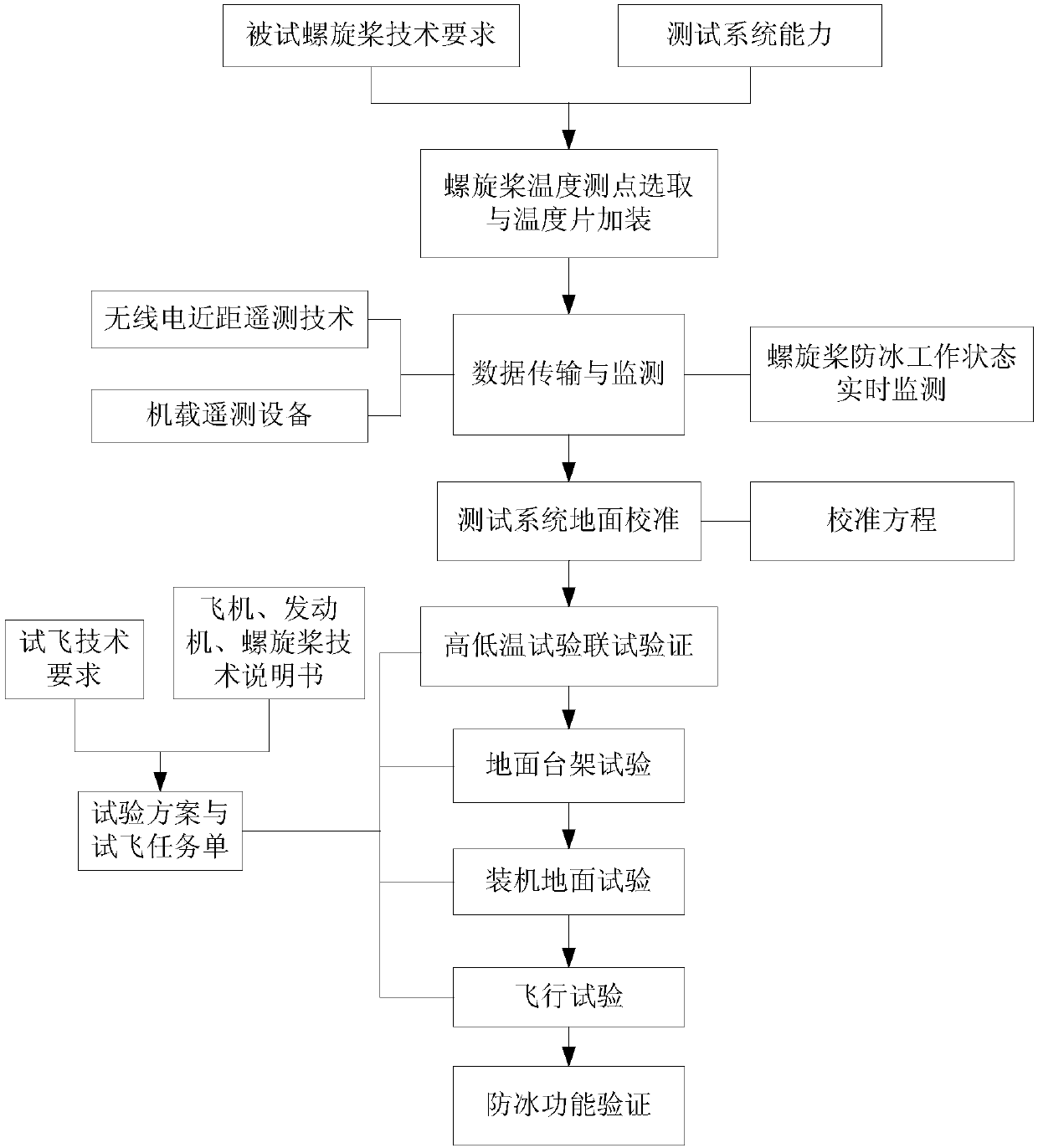

Pusher-type aero-propeller anti-icing function verification flight test method

A technology of aviation propellers and testing methods, which is applied in the testing of machine/structural components, measuring devices, measuring heat, etc., can solve the problems of unpredictable actual temperature, etc., and achieve the effect of high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

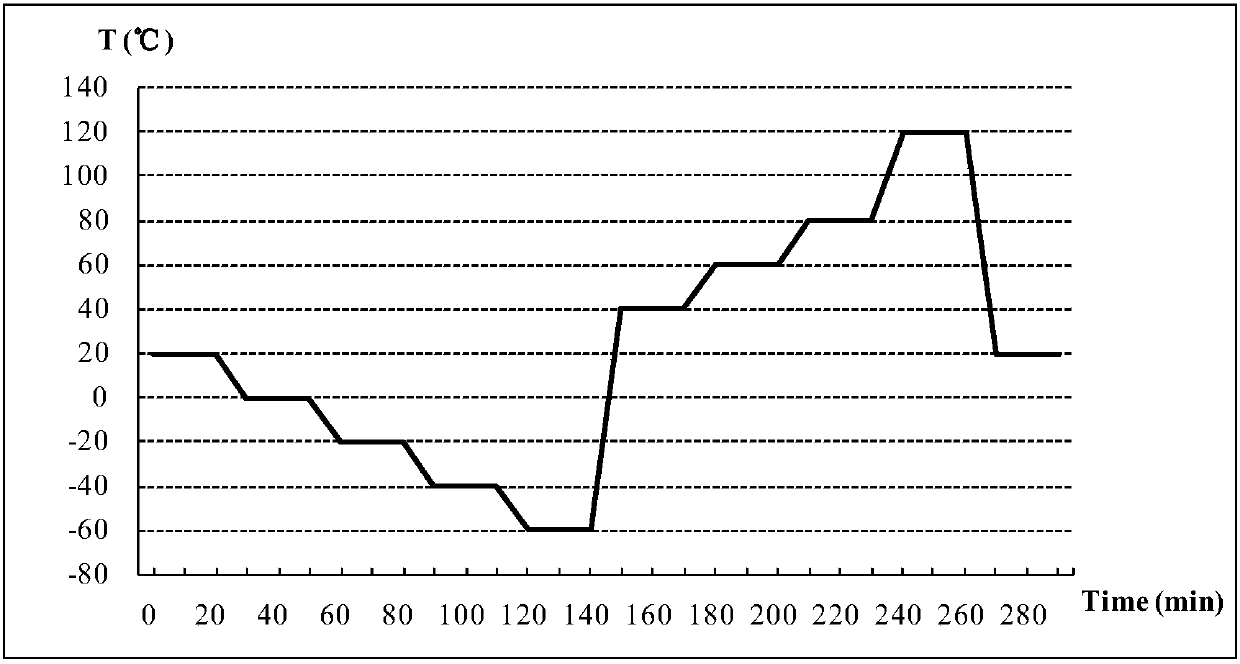

[0036] In the test flight of a certain type of propulsive aviation propeller aircraft, the method of this paper is used to test and verify the anti-icing function of the exhaust propeller of the aviation propeller. The specific implementation method is as follows:

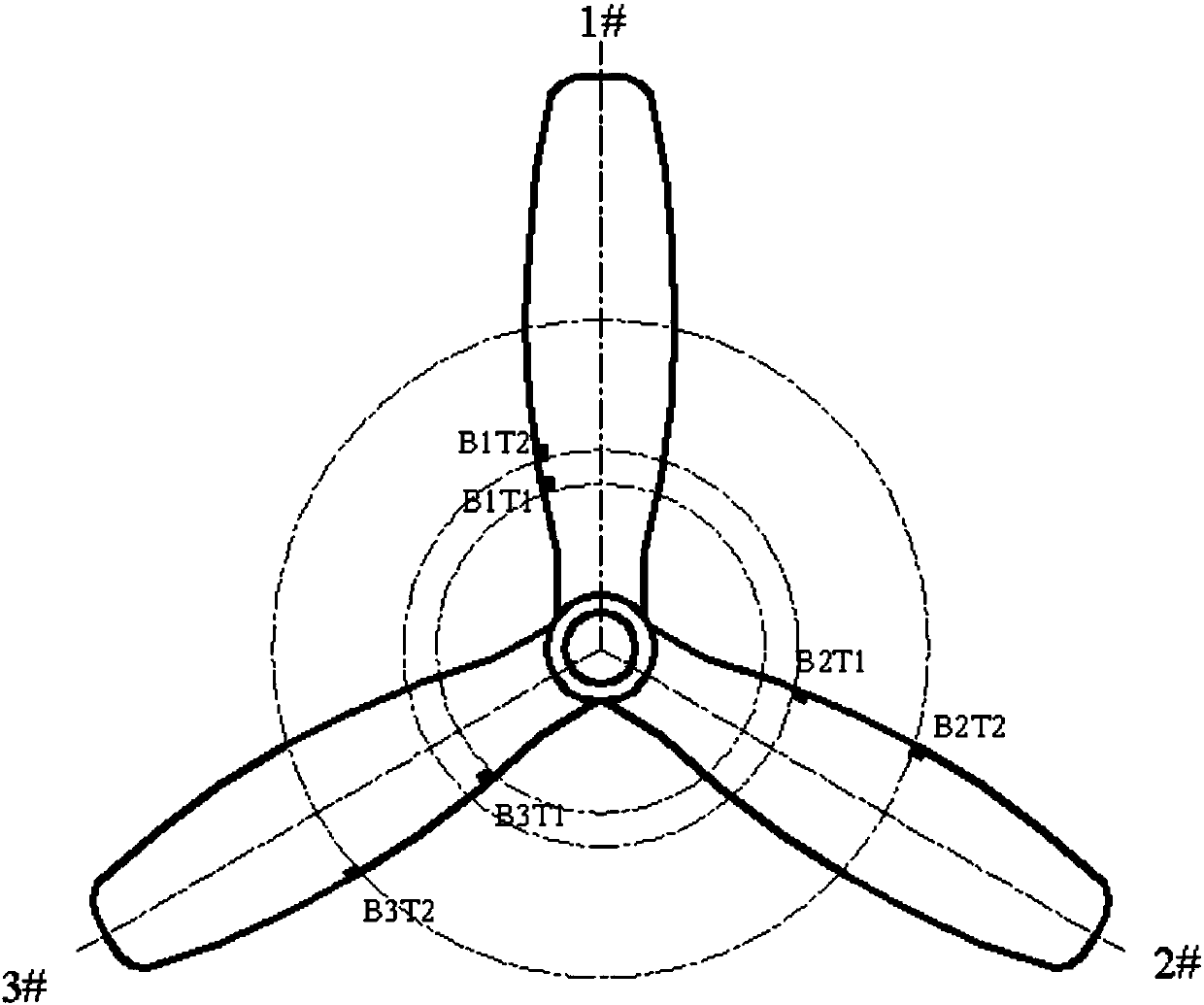

[0037] (1) Propeller temperature measuring point selection and temperature sheet installation

[0038] The tested propeller is a three-bladed propeller, such as figure 2 As shown, three sections of the propeller prone to icing are selected, and two temperature measuring points are selected on the convex front edge of each blade, and each two measuring points are mutually backup.

[0039] (2) Data transmission and monitoring

[0040] Using radio telemetry technology, a wireless telemetry transmitting device is installed on the propeller disk, and a wireless telemetry receiving device is installed at the rear end of the engine to form a test system, which realizes short-distance wireless transmission and collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com