A lead storage battery separator, preparation method and lead storage battery

A technology for lead-acid batteries and separators, which is applied in the fields of lead-acid battery separators and lead-acid battery production and preparation, can solve problems such as low wet elasticity of separators, battery capacity decline, etc., reduce electrolyte stratification, improve wet elasticity, The effect of increasing the twist factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0041] 1) Dissolve thermoplastic polyurethane (9180AL, Shanghai Yitan New Material Co., Ltd.) in a solvent to obtain a polyurethane solution;

[0042] 2) Add clean (purified) ordinary glass fiber (29°SR, Shenyang Jiuqing Dongxiang Glass Products Co., Ltd.) into 500 mL of the above polyurethane solution, stir and disperse and immerse for 30 minutes;

[0043] 3) Quickly filter and separate glass fiber;

[0044] 4) After using a small amount of dilute solvent to remove excess polyurethane solution on the surface, the modified glass fiber is obtained by drying treatment, and fiber accumulation should be avoided during the drying process.

[0045] The dosages of the substances in the specific examples are shown in Table 1.

[0046] Table 1

[0047]

[0048]

Embodiment 6

[0050] When the mass ratio of the modified glass fiber is 1%, the separator is prepared.

[0051] 1) Weigh 2g of the modified glass fiber prepared in Example 1 and ordinary glass fiber, and control the weight ratio to 1:99;

[0052] 2) Mix and beat the modified glass fiber and ordinary glass fiber in proportion;

[0053] 3) Use sulfuric acid solution to adjust the slurry pH to 2.5;

[0054] 4) The slurry is bubbled and dispersed, stirred, filtered, and dehydrated to obtain a wet separator;

[0055] 5) The wet separator is placed in a temperature of 200 DEG C for dehydration and dried to obtain the lead storage battery separator.

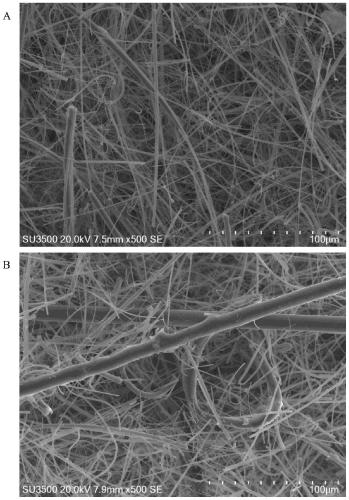

[0056] The prepared lead-acid battery separator was observed with a scanning electron microscope and compared with a separator prepared using only ordinary glass fiber. The results are as follows figure 1 Shown. figure 1 A is ordinary pure glass fiber separator, figure 1 B is the separator prepared in the experiment. by figure 1 It can be seen from B that ther...

Embodiment 7

[0058] When the mass ratio of the modified glass fiber is 5%, the separator is prepared.

[0059] 1) Weigh 2g of the modified glass fiber prepared in Example 2 and ordinary glass fiber, and control the weight ratio to 5:95;

[0060] 2) Mix and beat the modified glass fiber and ordinary glass fiber in proportion;

[0061] 3) Adjust the pH value of the slurry to 2.0;

[0062] 4) The slurry is bubbled and dispersed, stirred, filtered, and dehydrated to obtain a wet separator;

[0063] 5) The wet separator is placed in a temperature of 200 DEG C for dehydration and dried to obtain the lead storage battery separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com